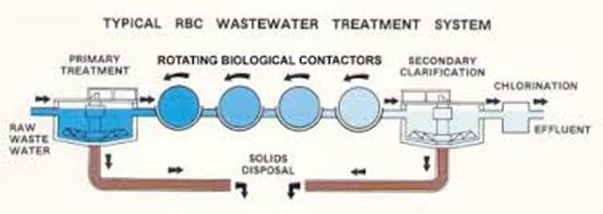

Sewage is treated using rotating biological contactors (RBCs) as a secondary treatment procedure. The RBC process involves enabling wastewater to come into touch with a biological medium, to eliminate pollutants in sewage prior to being released to the environment.

In this blog, we will understand what rotating biological contactors are, their design process and working in detail.

What are rotating biological contactors based sewage treatment plants?

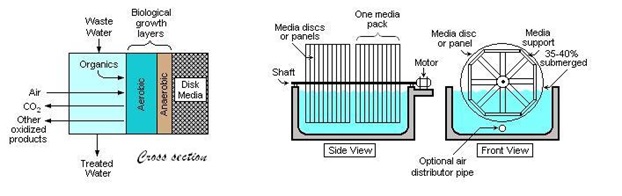

RBCs are fixed-bed reactors made up of stacks of spinning discs set on a horizontal shaft. They are also known as rotating biological filters. As wastewater passes through, they are rotated and partially submerged. After primary sedimentation of household grey or blackwater or any other biodegradable effluent, they are employed in typical wastewater treatment plants as secondary treatment process.

As the microbial community is alternatively exposed to the air and the sewage, dissolved organic contaminants and nutrients necessary for their breakdown, can be aerated and assimilated. These have been discovered to be especially successful for decentralised applications, on the level of a small to medium community or industry/institution, where electricity and skilled personnel are accessible.

Which processes mostly employ rotating biological contactors?

The RBC method may be employed where wastewater can be treated biologically. To reduce carbonaceous or nitrogenous oxygen demand to varying degrees, the RBC process can be applied in a variety of ways.

Because, there is no need to recycle effluent or sludge, the process is easier to run than activated sludge. Returning sludge digestion process supernatant to the RBCs requires special caution. Longer contact lengths (8 to 10 times longer than trickling filters) and a higher level of treatment are the two benefits of RBC technology.

Which factors consider the process selection of Rotating biological contactors or RBC’s in sewage treatment plants?

The level and consistency of treatment required, the type of waste to be treated, site restrictions, and capital and operational expenses, will all have an impact on the process mode that is most appropriate.

1: A precise determination of the influent, side-stream loadings, appropriate media sizing, equipment staging to meet effluent requirements, air requirements, and selection of an overall plant layout that will allow for flexibility in operation and maintenance, are all part of the process design of RBC facility.

2: To accurately obtain information for RBC design, it is advised to conduct a thorough on-site pilot plant evaluation that takes into account the variables, influencing the RBC performance.

3: Other methods to estimate RBC efficacy could be based on the outcomes of comparable full-scale installations, or meticulously documented pilot tests with the specific effluent. The treatment ability of sewage can be assessed using RBC pilot units with a small diameter. To reduce scale-up issues, each stage must be loaded below the oxygen transfer capability of a full-scale unit, while operating small-diameter units to gather design data.

The primary elements influencing the effectiveness of treatment in all RBC systems are:

· Wastewater properties are influenced by organic and hydraulic loading rates

· Wastewater temperature

· Biofilm control

· Dissolved oxygen levels

· Operation flexibility

Pretreatment in rotating biological contactors in STPs

Prior to the RBC process, effective grit, debris, and excessive oil or grease removal requires the use of primary settling tanks. Fine screens (0.03-0.06 inches) may be considered in some circumstances. In order to prepare materials for RBC units, screening and comminution are insufficient.

The RBC system design must take sulphide production into account. Where there is a risk of sulphide generation or increased organic and ammonia nitrogen loadings, separate facilities to accept and control feeding of septage waste or in-plant side streams, should be taken into account.

Design considerations of Rotating biological contactors or RBCs

· Unit's size

The main design factor for the RBC process is organic loading. The organic loading per unit of medium surface area per unit of time, or as BOD-5 per thousand square feet per day, is a common way to express this.

However, below 55°F, manufacturers must be contacted to get the various correction factors that must be used to establish, the required additional media surface area. Wastewater temperatures over 55°F have a little impact on organic removal and nitrification rates.

The following variables should be used to calculate design-loading rates for RBCs:

• Design flow rates

• The concentration of soluble influent BOD-5

• Temperature of sewage

• Primary effluent oxygen concentration

• Media surface area

• The number of stages

• The layout of the media within each stage

• The speed at which the medium rotates

• The duration of retention in the RBC tank

• Peak loading, maximum BOD-5/average BOD-5

In addition to the aforementioned variables, influent DO concentration, influent ammonia nitrogen concentration, influent total Kjeldahl nitrogen (TKN), diurnal load changes, pH and alkalinity, and the permitted effluent ammonia nitrogen concentration, will all affect loading rates for nitrification. Since, soluble BOD-5 loading is an important factor in the design of RBC units, it should, if possible, be confirmed by influent sampling.

· Peak/average rates

For design purposes, typical conditions can be taken into account when the peak :average flow ratio is 2.5:1.0 or below. Flow equalisation should be taken into consideration for larger flow ratios.

Here, the first-stage standard density media should receive an organic loading of 1.5 to 2.5 pounds of soluble BOD-5, or 3.5 to 6.0 pounds of total BOD-5 per thousand square feet per day. When first-stage organic loadings exceed 6 pounds of total BOD-5 or 2.5 pounds of soluble BOD-5 per thousand square feet per day, there is a higher chance that issues such as excessive biofilm thickness, dissolved oxygen depletion, nuisance species, and deteriorated process efficiency would arise.

Now, on the first-stage shaft(s) of any treatment train, the design loading should not be greater than 2.5 pounds of soluble BOD-5/1,000 square feet of standard media surface per day. The first-stage shafts may need further aeration on occasion, when heavy organic loadings are present. The first-stage RBCs shouldn't be cultured in high-density medium.

Also, design loading for first high-density media shaft encountered after the first two shafts, or rows of shafts in a treatment train for peak conditions, shall not be greater than 2.0 pounds of soluble BOD-5/1,000 square feet.

Finally, the total system loading for average conditions shall not be greater than 0.6 pounds of soluble BOD-5/1,000 square feet of medium. The total number of shafts needed should be calculated, using this soluble BOD-5 loading to all shafts.

· RBC medium

To maximise the elimination of BOD and ammonia nitrogen (NH3-N), staging of RBC medium is advised. RBCs must be built with a minimum of three steps per flow route in secondary treatment applications.

It is advised to use a minimum of four steps per flow channel for combined BOD-5 and NH3-N removal. As long as inter stage baffles are built inside the tank and the flow is introduced parallel to the shaft, multiple stages on a single shaft are acceptable for minor installations.

Also, when using numerous process trains, it is recommended to introduce the flow channel perpendicular to the shafts, and to spread the wastewater equally across the face of the RBCs, whenever there are three or more shafts in a row.

When possible, influent sampling must be used to correctly define the organic loading. It is undesirable to determine simply the estimated load on the shafts for existing facilities, which are to be enlarged or renovated. After initial clarity, flow and load samples are required to show the load, which is often achieved via composite sampling. The influent and effluent soluble:total BOD-5 ratio, can be taken to be 0.5 in order to estimate effluent quality for a variety of loadings.

· Surface flow rate (SOR)

When primary clarification is performed before the final stage of RBC system treating municipal wastewater or sewage, the concentration of suspended particles that exits the system is typically less than 200 mg/l.

Secondary clarifiers must be utilised with RBCs for secondary effluent quality standards to be met. For secondary clarifiers, the surface overflow rate typically shouldn't exceed 800 gallons per day per square foot. To increase effectiveness, you can think about covering the clarifiers.

How do Rotating biological contactors work in sewage treatment plants?

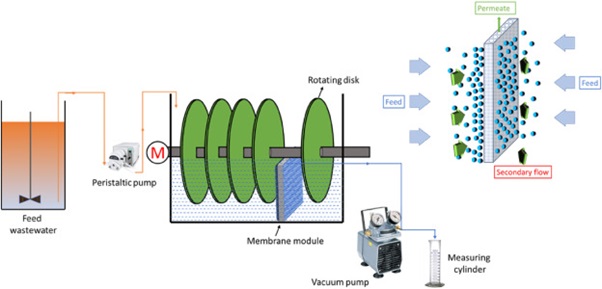

1: It consists of a shaft through which wastewater runs and is equipped with a number of lightweight circular revolving discs. The discs slowly rotate through the sewage while being partially immersed. The discs are typically ridged, corrugated, or lattice-like to improve the specific surface area. They are most frequently formed of high-density plastic sheets such as polyethylene, polystyrene, or polyvinyl chloride.

2: Bacteria can cling to the discs' surfaces, and as the discs rotate, a layer of biomass builds up there. The rotation of this biofilm exposes it alternately to the air and to the wastewater.

3: As the biofilm on the disc is rotated out of the liquid, the oxygen required for the growth of these microorganisms is absorbed from the air. The biofilm absorbs nutrients and organic contaminants, as it moves through the liquid phase.

4: The growth of the microbe and the conversion of the organic matter to CO2 require all available oxygen, nutrients, and organic contaminants. Nitrification removes nitrogen by turning it into gaseous N2, which is then released into the atmosphere, and denitrification follows. By altering the rotational speed and submersion depth, the process is optimised.

5: To give more oxygen in the event of high-strength influents, air is sometimes injected to the tank's bottom.

6: A typical spinning speed is between 1 and 2 rpm and the submerging level ranges from 40 to 80%. The typical disc diameter ranges from 0.6 to 3 metre.

7: Due to the longer contact duration in rotating blood cells (RBCs), sewage treatment levels can be up to 8 to 10 times greater than in trickling filters. RBCs are typically more dependable than other fixed-film materials, because the rotation permits both optimal wetting and oxygen supply.

8: Additionally, the disc's design allows for the attachment of substantial volumes of biofilm, indicating the presence of substantial biological mass capable of degrading the contaminants.

9: In comparison to traditional activated sludge processes, the substantial volume of biomass and the stability of contact also lead to greater stability, and a decreased vulnerability to fluctuations in hydraulic or organic loading.

10: As with all fixed-film processes, excessive oil, grit, and debris must be removed through initial settling or screening. Anaerobic reactors, Imhoff tanks, or septic tanks are common examples of such primary treatments. A post-settling unit (i.e., a clarifier) is also necessary to remove excess sludge.

11: The shearing forces generated by the rotating discs combined with gravity cause extra biomass to slough off the discs. Sloughed solids are kept in suspension by the rotation movement, so they can be transported to a clarifier (gravity settler) for secondary settling.

12: For stabilisation, the clarifier's collected sludge needs additional treatment, such as anaerobic digestion, composting, artificial wetlands, ponds, or drying. Accumulated sludge is frequently returned to the septic tank for storage, and partial digestion in small installations.

13: Although they are a supply of water, RBC's effluents do not contain significant amounts of nutrients, and are hence not very interesting for agriculture. RBC effluents need to undergo additional treatment, such as sand filtering, artificial wetlands, RO Plants, or another type of disinfection such as chemical disinfection or UV disinfection, to reduce elimination of microorganisms.

14: RBCs are frequently covered with a fibreglass casing to shield the discs from sunshine, wind, rain, and cold temperatures.

Applications of Rotating Biological Contactors

RBCs may effectively remove biodegradable organic contaminants from both home black or greywater, and highly concentrated industrial wastewater from sources like bakeries, dairies, food processors, pulp, and paper mills, etc.

Numerous uses are recognised, including decentralised applications at the level of small to medium-sized communities, companies, or institutions, as well as post-treatment for activated sludge operations in traditional household wastewater treatment facilities. They are primarily designed for urban environments, where there is little need for land but a constant need for energy and, thus, for semi-skilled labour.

Advantages of Rotating Biological Contactors

· High effluent quality, i.e., both BOD as well as nutrients and high contact time

· High process stability, stress resistance, and organic or hydraulic loading

· The vast active surface necessitates short contact times

· Low need for space

· Excess sludge that drains readily accumulated in clarifier

· There is no channelling risk

· Low generation of sludge

Disadvantages of Rotating Biological Contactors

· Continuous electricity supply is necessary, albeit it consumes less energy for equivalent degradation rates, than trickling filters or activated sludge processes

· No contact media available at the neighbourhood market

· High initial investment and on-going operating and maintenance expenses

· Protection from the sun, wind, and rain is required particularly in cold climates to prevent freezing

· Odour issues could arise

· Operation and maintenance require permanent expert technical manpower

Learn more about our advanced treatment options for sewage

Sewage is harmful to the environment and to people's health. To prevent pollution from sewage, poisonous and dangerous substances that are released into the water must be eliminated.

That is why; Netsol Water provide various sewage treatment solutions for treating sewage. We also provide outstanding wastewater solutions for any sector with high-quality, as well as dependable products and a knowledgeable engineering group. To find out more, get in touch with us at +91 9650608473 or email at enquiry@netsolwater.com.