What are Rotating Biological Contactors?

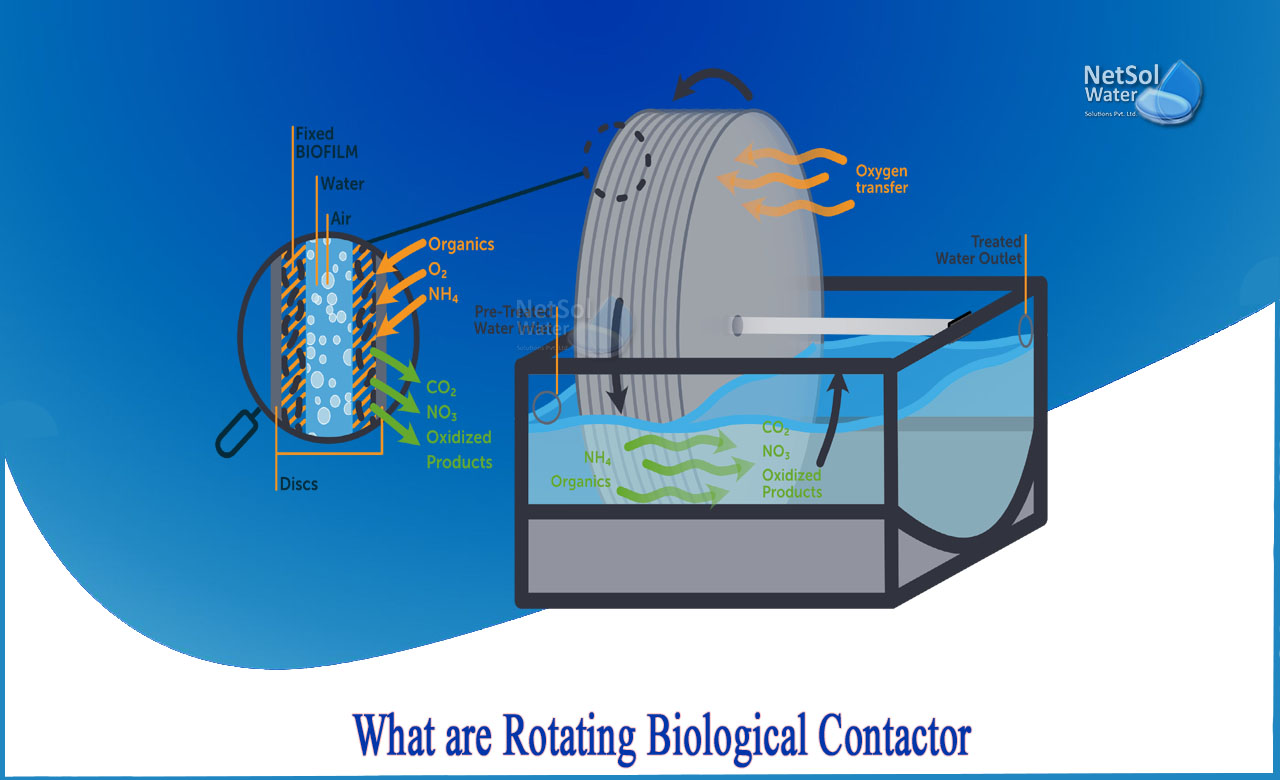

Rotating biological contactors (RBCs) are biological solid membrane treatment processes used in the secondary treatment of wastewater after the primary treatment.

The pre-treatment process includes the removal of sand and coarse suspended solids by the screening process, followed by the sedimentation of suspended solids. The RBC process removes pollutants from wastewater by contacting it with a biological film before the treated wastewater is discharged into the environment [usually a body of water (river, lake, or ocean)].

What are RBC’s made up of?

Rotating biological contactors are a type of secondary (biological) processing process. It consists of a series of dense parallel discs mounted on a rotating shaft that is carried just above the surface of the sewage. Microorganisms grow on the surface of pane, where biological degradation of wastewater pollutants takes place. The Rotary Biological Contactor (RBC) can withstand overvoltage in the event of organic loads.

Working of Rotating Biological Contactors

1. For microorganisms to succeed, they need both oxygen to live and food to grow. As the disc rotates, oxygen is extracted from the atmosphere. As the microorganism grows, it accumulates on the medium until the shear forces of the rotating disc shed the microorganism in the wastewater. The wastewater from the RBC then passes through a purifier, where flaky biological solids settle in suspension as sludge.

2. Rotating disc packages (so-called media) are placed in tanks or tabs and rotate at 2-5 revolutions per minute. Commonly used plastics for media are polyethylene, PVC, and Styrofoam. The shaft is aligned with the sewage stream so that the disc rotates at right angles to the flow, and usually several packings are combined to form the sewage pipe. About 40% of the disk surface is submerged in wastewater.

3. Biological growth deposits on the surface of the disc, forming a layer of mucus. The disc brings wastewater into contact with the atmosphere for oxidation as it spins. Rotation helps loosen excess solids. The disc system can be daisy-chained to achieve almost any degree of residence or removal required. The system is layered so that later stages of culture can become accustomed to slowly deteriorating materials.

What are discs made up of?

Discs are made of plastic sheets up to 2-4 m in diameter and 10 mm thick. Multiple modules can be placed in parallel or in series to meet flow and processing requirements. The disc is submerged in sewage up to about 40% of its diameter. Therefore, about 95% of the surface isalternately submerged in wastewater and then exposed to the atmosphere above the liquid. Carbon-containing substrates are removed in the early stages of RBC. Carbon conversion can be completed in the first stage of a series of modules and nitrification is completed after the fifth stage.

How does RBC’s attain nitrification of waste water?

Most RBC systems contain at least four or five modules in series to achieve nitrification of wastewater. As biofilm biomass changes from carbon metabolism to nitrification, there is a visual colour change from Grey/beige to brown. The left-to-right colour change of the biofilm from Grey/beige to brown indicates a slow change from carbon-metabolizing bacteria to nitrogen-metabolizing bacteria.

The biofilm, which is a biological growth that adheres to the pane, absorbs organic matter (measured as BOD-5) in the wastewater. Aeration is carried out by a rotational process in which the media is exposed to the air after it meets the sewage, thereby facilitating the decomposition of the pollutants removed. The degree of wastewater treatment depends on the surface of the medium and the quality and quantity of inflowing wastewater.

The RBC regularly achieves the following emission parameters for treated wastewater:

BOD-5: 20 mg/L, suspended solids: 30 mg/L, and Ammonia N: 20 mg/L.

Due to the slow rotation of the rotor (25rpm), it consumes very little power and is quiet. These are generally considered to be very robust and low maintenance systems. Better drainage parameters can be achieved by adding a tertiary polishing filter after the RBC to lower BOD-5, SS, and ammonia nitrogen. Additional UV or chlorination steps can be used to achieve wastewater parameters that make the water suitable for irrigation or toilet flushing.

For designing, manufacturing and installation of RBC’s, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.