What are Biofilms and what role do they play in wastewater treatment?

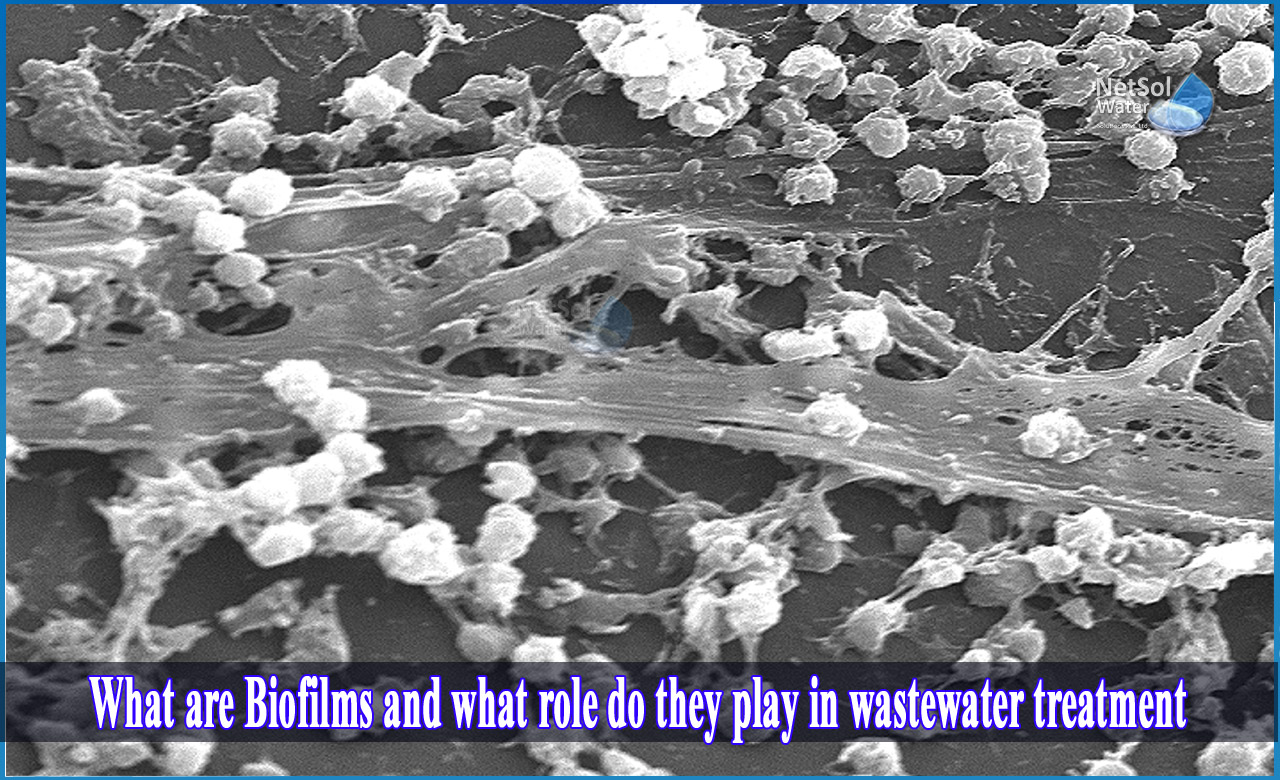

A biofilm is any syntrophic consortia of microorganisms in which cells adhere to one another and, in certain cases, to a surface. These adhering cells are encased in a slimy extracellular matrix made up of extracellular polymeric molecules or EPS. The EPS components are often a polymeric agglomeration of extracellular polysaccharides, proteins, lipids, and DNA produced by the cells inside the biofilm.

Biofilms may form on live or non-living surfaces and are common in natural, industrial, and medical environments. Microbial cells developing in a biofilm differ physiologically from planktonic cells of the same organism, which are single cells that may float or swim in a liquid media.

Why do microbes produce biofilms?

Microbes produce biofilms in response to a variety of circumstances, including cellular identification of particular or non-specific attachment sites on a surface, nutritional signals, and, in certain cases, exposure of planktonic cells to sub-inhibitory antibiotic doses. When a cell converts to the biofilm mode of development, it experiences a phenotypic shift in behaviour that involves the differential regulation of a large number of genes.

Biofilm production in wastewater treatment systems

Biofilm systems are well-developed technologies in which solid media are added to suspended growth reactors to provide attachment surfaces for biofilms in order to increase microbial concentrations as well as rates of contaminant degradation to take advantage of a number of removal mechanisms, including biodegradation, bioaccumulation, biosorption, and biomineralization.

The microbial populations in the biofilm degrade several nutrients, including phosphorus and nitrogen-containing chemicals, carbonaceous materials, and pathogens trapped in the wastewater. Following the removal of contaminants, cleaned water from a biofilter is either released into the environment or used for agricultural and other recreational activities.

What are the advantages of such systems?

Wastewater treatment with biofilm systems has several advantages, including operational flexibility, low space requirements, reduced hydraulic retention time, environmental resilience, increased biomass residence time, high active biomass concentration, enhanced ability to degrade recalcitrant compounds, and a slower microbial growth rate, which results in lower sludge production.

Biofilm formation on various filter media

The basic unit of connected growth wastewater treatment methods is packing or filter media. It gives a surface for the biofilm to develop on.

1: The filter media must be long-lasting, insoluble, and chemically resistant. It is chosen based on its size, porosity, density, and resistance to erosion and chemicals.

2: The ideal medium has a high specific surface area, a cheap cost, and a high porosity to prevent clogging and facilitate airflow. The surface area and shape of the support materials influence the hydrodynamic conditions in the reactor, which in turn influence biofilm growth, which in turn influences wastewater treatment.

3: Various synthetic and natural materials are used. Polystyrene, polypropylene, tire-derived rubber, and pebbles have all been employed as bio-filter medium in fixed biofilm reactors for wastewater treatment by various companies.

4: The chemical composition of the filter medium is particularly important in terms of compatibility with growing biofilms.Various spectroscopic methods, like as X-ray photoelectron spectroscopy (XPS) and energy-dispersive X-ray spectroscopy, can be used to identify and quantify components in a filter media (EDS or EDX or XEDS).

Role of Netsol in Wastewater Treatment

Netsol Water's wastewater treatment solutions include neutralization, filtration, extraction, separation, and recycling of wastewater streams. Our hazardous and non-hazardous wastewater handling facilities provide environmentally pleasant wastewater solutions. We also employ tried-and-true procedures and cutting-edge equipment’s to produce regulatory-compliant effluent.

For further information or product purchase related questions, call on +91 9650608473 or email at enquiry@netsolwater.com.