What is Multi Effect Evaporator in Zero Liquid ETP Plant?

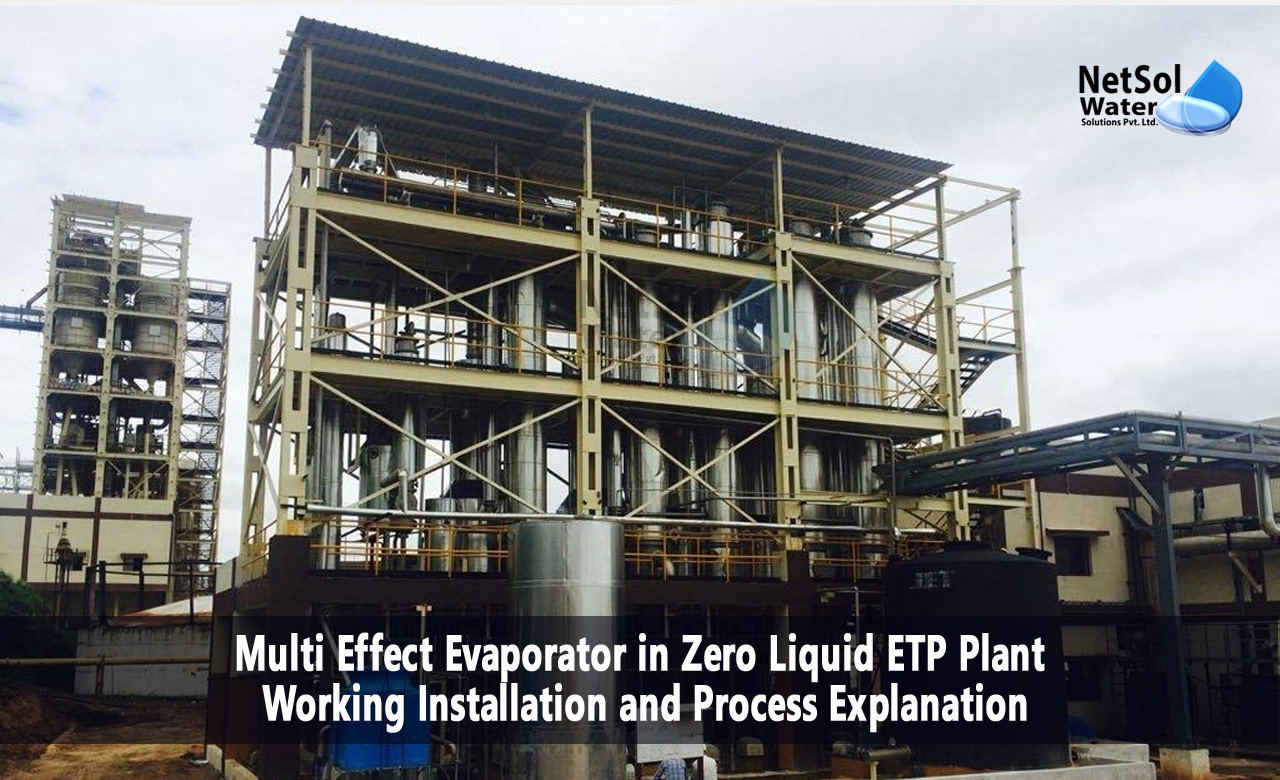

Zero Liquid Effluent Treatment Plant is an important aspect of environmental management in industries. The Multi Effect Evaporator (MEE) is an essential component of such plants, and it plays a crucial role in the effective treatment of effluents.

In here, we will discuss how MEE works in Zero Liquid Effluent Treatment Plant, and we will explain the process flow diagram in detail. We will also discuss the installation process of the Multi Effect Evaporator in the Effluent Treatment Plant.

How does Multi Effect Evaporator work in Zero Liquid Effluent Treatment Plant?

The Multi Effect Evaporator (MEE) is a process that concentrates the effluent by evaporating the water content. The MEE operates under vacuum conditions, which helps in reducing the boiling temperature of the liquid, thereby reducing the energy requirement.

MEE is designed in such a way that it recovers almost 95% of the water from the effluent, and the remaining 5% gets converted into solid waste. This makes MEE a highly effective tool for Zero Liquid Effluent Treatment Plants.

The MEE process involves multiple stages, and each stage is called an effect. The number of effects in an MEE is determined by the concentration ratio required to achieve the desired concentration of the effluent. In a typical MEE, there are 3-5 effects, and each effect is a heat exchanger and a flash chamber.

The MEE works on the principle of the heat transfer from one effect to another. The concentrated effluent from the first effect is fed to the second effect, and the steam generated in the second effect is used to heat the feed for the third effect. This process is repeated for all the effects until the final product is obtained.

Installing a multi-effect evaporator

Let us see the steps involved in installing a multi-effect evaporator in an effluent treatment plant:

Step 1: Site Preparation

Before installing the multi-effect evaporator, you need to prepare the site by ensuring a level ground, sufficient space, and access to utilities such as electricity, water, and compressed air. It is essential to ensure that the site is safe and complies with local regulations.

Step 2: Unpacking and Inspection

Once the site is ready, unpack the multi-effect evaporator carefully, and inspect all the components for any damages that may have occurred during transportation. Ensure that all the components are intact and free from any defects before proceeding to the installation.

Step 3: Installation of the Evaporator

Begin the installation of the evaporator by assembling the individual components, such as the heat exchanger, vapor separator, and condenser. Install the piping, valves, and pumps to connect the various components. Ensure that all the connections are tight and leak-free.

Step 4: Electrical and Instrumentation Connections

Once the evaporator is installed, make the electrical connections as per the manufacturer's instructions. Install the necessary instrumentation such as temperature, pressure, and level sensors to monitor the system's performance.

Step 5: Commissioning and Testing

Before commissioning the system, conduct a thorough inspection and testing of all the components. Check for any leaks, malfunctioning equipment, and proper functioning of the control system. Once satisfied with the results, commission the system and start the operations.

Step 6: Operation and Maintenance

After commissioning the system, operate the multi-effect evaporator as per the manufacturer's instructions. Regularly monitor the system's performance, including temperature, pressure, and flow rates, and take corrective action if necessary. Conduct regular maintenance of the system to ensure its longevity and efficient performance.

Process steps of Multi Effect Evaporator:

The process of MEE is shown below in a flow diagram:

Summary:

In conclusion, the installation of a multi-effect evaporator in an effluent treatment plant requires careful planning, preparation, and execution. It is essential to follow the manufacturer's instructions and local regulations to ensure the safety and efficient operation of the system. Regular maintenance and monitoring will help ensure the system's longevity and optimal performance.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.