Introduction

Increased effectiveness and efficiency have been carefully considered, when developing new treatment technologies. The main treatment stage, when significant amounts of particulates are separated and removed from the influent solution, is the one particular area that can be improved. Before coagulation was developed and demonstrated to reduce detention time, sedimentation had been utilized independently for some time.

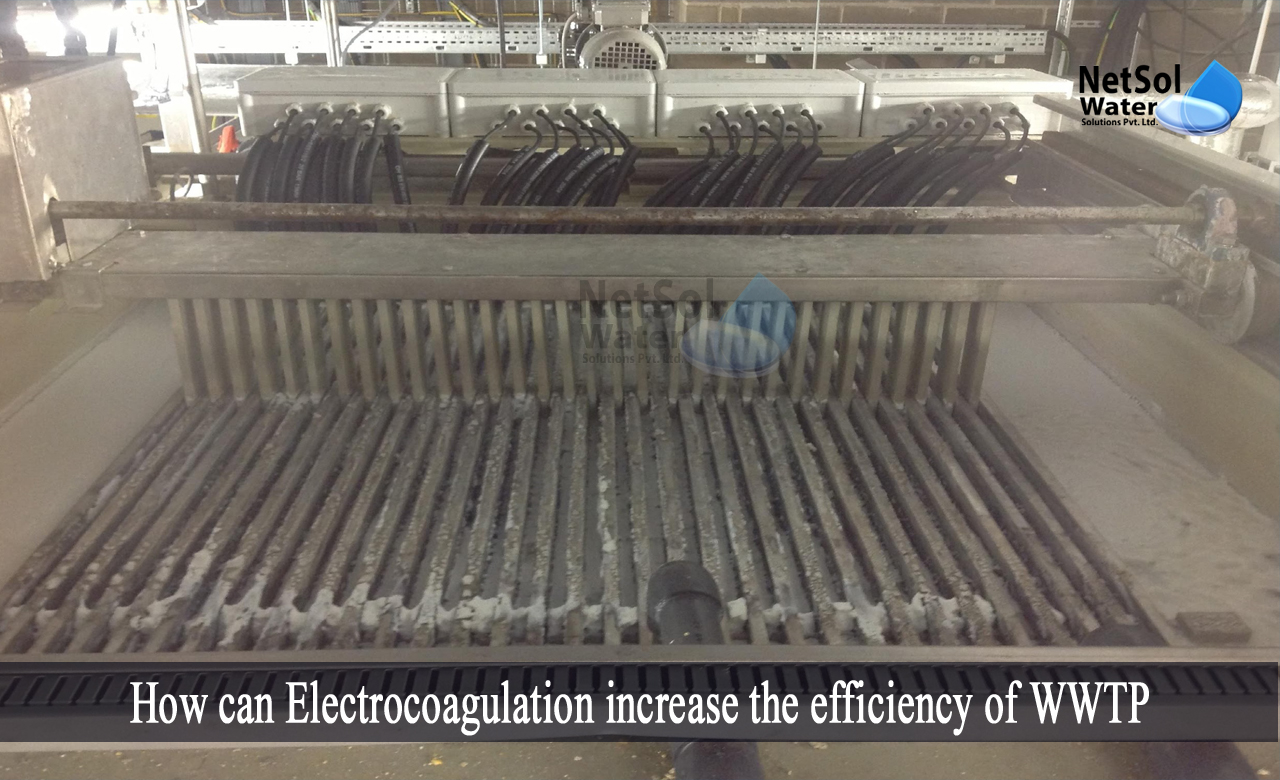

Even more recently, an upgraded coagulation technique—an electrochemical variation of the old, i.e., electrocoagulation is unveiled. For many industrial and municipal client applications, adding electrocoagulation to a wastewater treatment process can increase treatment effectiveness, in the main or tertiary treatment stages.

What is electrocoagulation?

The purpose of electrocoagulation is to destabilize pollutants and increase particle size, to facilitate simpler settling and filtering. Due to their similar charges, particles will naturally settle on their own, but it may take some time. The particles will reject one another if their charges are comparable, making it challenging for them to settle to the bottom of their container.

When electricity is given to the electrodes, the cathode oxidises, causing corrosion. The metallic particles are discharged into the solution, neutralizing the solution's overall charge. When this occurs, the particles start to gather and are propelled towards the system's top by hydrogen bubbles, before eventually falling or settling. In this process, even some of the smallest particles are engaged.

How can Electrocoagulation increase the efficiency of WWTP?

There are several ways that electrocoagulation might improve the effectiveness of an industrial wastewater treatment:

· TSS and TDS reduction

The decrease of solids, both suspended and dissolved, is one of the main objectives of EC. TSS is effectively removed by EC, and TDS reduction depends on the TDS composition of the particular wastewater stream.

This technique makes it possible for the subsequent phases, in the wastewater treatment process to go without a hitch. This method allows for a more effective reduction of TSS and TDS in fewer steps. If fewer impuritiesare present, the more efficiently the manufacturing process can operate, if the company chooses to reuse the water.

· Less amount of sludge is produced

The large amounts of sludge produced by alternative treatment methods, are a significant problem as well. After that, the sludge needs to be dewatered and disposed of. Some sludge may be more challenging to dewater than others, and some sludge may be too dangerous to be disposed of, without incurring additional costs.

Much of this can be avoided using electrocoagulation. Sludge is produced by EC, although it is much less abundant and easier to dewater. Due to the sludge's non-toxicity, disposal would not incur any additional costs. Instead of only being dumped in a landfill, the EC sludge may also be used as a useful soil enhancer.

· Use of less chemicals

Chemical coagulation, which is the traditional equivalent of electrocoagulation, needs a lot of chemicals to produce the coagulation effect. Contrarily, EC only needs chemicals for occasional electrode cleaning, and straightforward pH changes. The sludge is dangerous because of the chemical additives used, in the chemical coagulation process.

· Maintenance is less

EC's simplicity is another great asset. Due to the low number of parts and ease of maintenance, industrial wastewater treatment efficiency is optimized. The electrodes must be cleaned appropriately to ensure their longevity. This calls for a dilute acid rinse and electrode polarity adjustment, initiated by the system control panel.

· Simple Operation

There is no extensive training needed to operate an EC machine. With the capacity for remote monitoring, most of it can be configured to be done automatically. Additionally, as this procedure uses almost no chemicals, any impurity modifications only requires a quick pH change or a change in power.

Conclusion

Electrocoagulation is a cutting-edge method for treating wastewater, and excels in many areas where chemical coagulation falls short. Many businesses and municipalities, may easily boost the efficacy of their wastewater treatment process, by putting in place an EC system.

How can we assist?

Industrial enterprises and municipal clients can get the industrial wastewater treatment process efficiency they need, by utilizing a tailored EC system from Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.