Use of commercial RO Filter systems in textile industry

The textile industry is one of the largest consumers of water worldwide, with water being used in every step of the textile manufacturing process. The industry requires high-quality water for various processes, including dyeing, printing, finishing, and more. However, the use of water in the textile industry also results in the generation of significant amounts of wastewater that needs to be treated before discharge. Commercial Reverse Osmosis (RO) filter systems have emerged as an effective solution for the textile industry to treat their wastewater and provide high-quality water for their processes.

In this blog, we will discuss the use of commercial RO filter systems in the textile industry, along with a flow chart outlining the process.

RO Technology for Textile Industry

Reverse Osmosis (RO) technology is a water purification process that removes impurities from water by forcing it through a semipermeable membrane. RO technology is highly effective in removing dissolved salts, minerals, and other impurities from water. Commercial RO filter systems are designed to handle high volumes of water and are scalable to meet the demands of the textile industry.

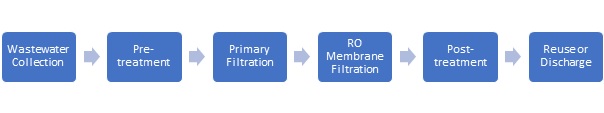

Flow Chart of RO Process for Textile Industry

- Wastewater Collection: The first step in the RO process for the textile industry is the collection of wastewater generated during the various stages of textile manufacturing.

- Pre-treatment: The wastewater collected needs to undergo pre-treatment to remove any large particles, sediments, and other contaminants that may damage the RO membrane. This process involves the use of screens, grit chambers, and settling tanks.

- Primary Filtration: The pre-treated wastewater is then sent through a primary filtration system, which involves the use of multimedia filters to remove any remaining suspended solids, oils, and grease.

- RO Membrane Filtration: The primary filtered water is then fed into the RO system, where it passes through a semipermeable membrane that removes dissolved salts, minerals, and other impurities from the water.

- Post-treatment: Once the water has passed through the RO membrane, it undergoes post-treatment to improve its quality. This process may involve adjusting the pH level, adding minerals back to the water, and disinfecting the water to remove any remaining bacteria or viruses.

- Reuse or Discharge: The purified water can either be reused in the textile manufacturing process or discharged into the environment, depending on the regulatory requirements and the quality of the water.

Benefits of Commercial RO Filter Systems for Textile Industry

- Cost-effective: The use of commercial RO filter systems for the textile industry is cost-effective as it reduces the need for freshwater intake and lowers the cost of wastewater treatment.

- Environmentally Friendly: The use of commercial RO filter systems in the textile industry is environmentally friendly as it reduces the amount of freshwater required for textile production, conserves natural resources, and reduces the amount of wastewater discharged into the environment.

- High-quality Water: Commercial RO filter systems produce high-quality water that meets the regulatory requirements for discharge into the environment or reuse in textile production.

- Scalable: Commercial RO filter systems can be scaled up or down to meet the demands of the textile industry, making it an ideal solution for businesses of all sizes.

- Low Maintenance: Commercial RO filter systems require minimal maintenance, with most systems only needing filter changes and occasional membrane replacement.

- Increased Efficiency: The use of commercial RO filter systems in the textile industry can increase the efficiency of the manufacturing process by reducing the need for water and wastewater treatment, leading to cost savings and improved productivity.

Conclusion

The textile industry requires large volumes of high-quality water for various processes, resulting in the generation of significant amounts of wastewater that needs to be treated before discharge. Commercial RO filter systems have emerged as an effective solution for the textile industry to treat their wastewater and provide high-quality water for their processes. The use of commercial RO filter systems is cost-effective, environmentally friendly, and produces high-quality water that meets regulatory requirements. With minimal maintenance and scalability, commercial RO filter systems are a smart investment for the textile industry looking to improve their water management practices.

For any other support, inquiries, or product purchases, call on +91-9650608473 or email at enquiry@netsolwater.com