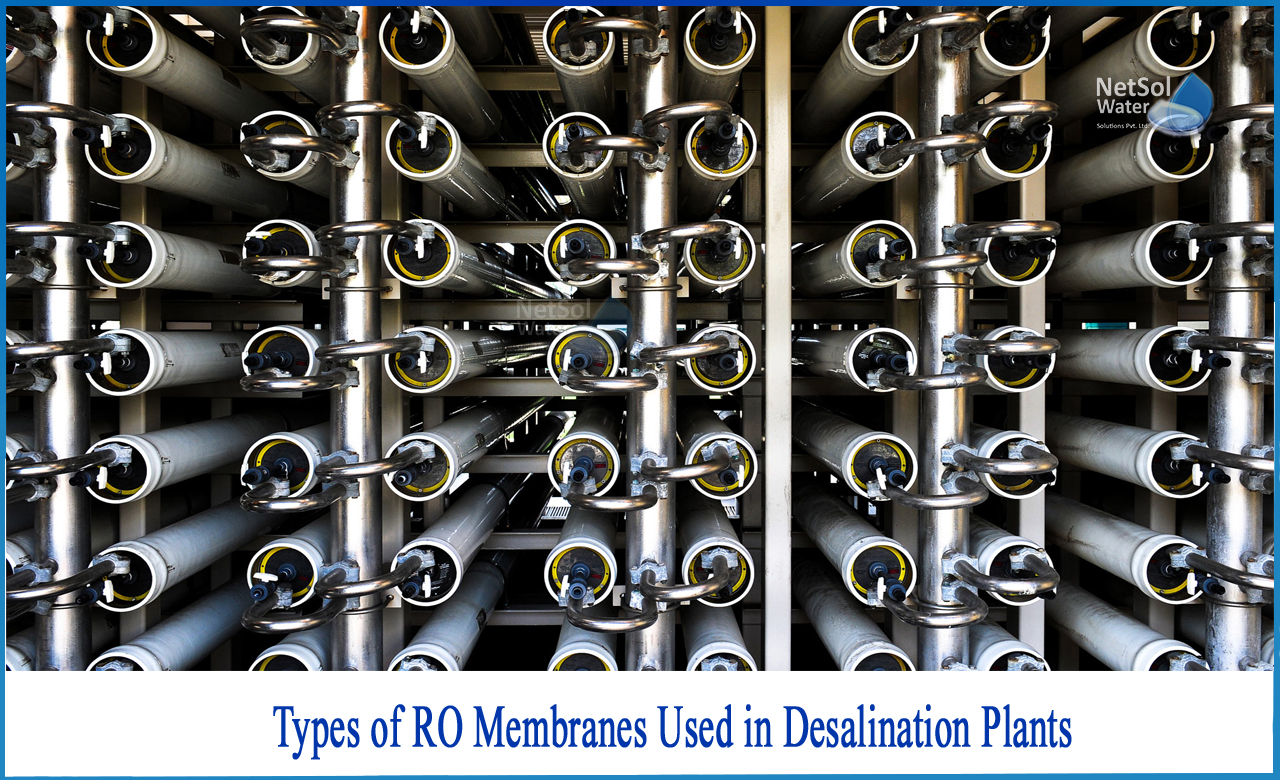

How many Types of RO membranes used in desalination plants?

Due to a growing scarcity of fresh water supplies, a movement for alternate resources such as ocean water has gained traction. Membranes for water desalination were first investigated in the 1970s. Membranes became a viable alternative to evaporation-based technologies in the water treatment business after proving effective at creating pure water from salt water.

Types of RO membranes used in desalination plants

1: Cellulose-Based Membranes

These membranes are made up of acetylated cellulose. These membranes are mechanically resilient because they are made of a linear, rod-like substance that is relatively inflexible.

The degree of acetylation in commercial CA membranes used for reverse osmosis is around 2.7. The salt rejection and permeate flow are well balanced in this mixture. CA and CTA mixes are also used in certain membranes. Combining CA with CTA improves mechanical stability and hydrolysis resistance while lowering permeability.

These membranes provide a number of benefits over other RO membranes now available in the market. They are simple to construct and have great mechanical qualities. They're also relatively resistant to chlorine damage. These membranes can survive up to 5 ppm of free chlorine, which is far more than other membranes, such as those made of aromatic polyamides, can endure.

These membranes have flaws as well, which modern membranes have attempted to overcome. They membranes have a tendency to hydrolyse with time, reducing selectivity. They are also exceedingly sensitive to pH fluctuations, being stable only in the pH ranges of 4 to 63. As the temperature rises, the salt rejection of CA membranes diminishes. As a result, the temperature of the input water rarely exceeds 35°C.

2: Thin Film Composite Membranes

Until the introduction of thin film composite (TFC) RO membranes in 1972, cellulose acetate membranes were the most popular choice for RO membranes.

A porous, highly permeable support, such as polysulphone, is covered with a cross-linked aromatic polyamide thin film in most TFC membranes. The membrane's salt rejection characteristics are provided by the coating.

TFC membranes provide several benefits over CA membranes, in addition to high rejection and flux. They can, for example, reject certain organics with low molecular weight. They're also more stable at greater temperatures and over a wider pH range than CA. TFC membranes, on the other hand, have a sensitivity to chlorine. Chlorine is very damaging to these membranes. Ring chlorination is thought to occur in the polyamide, disrupting hydrogen bonding between chains and degrading the polymer matrix. Salt rejection is drastically reduced as a result of this occurrence.

Unfortunately, most TFC membranes can only withstand chlorine exposure for up to 1000 ppm-hours. Because this limit is much lower than the CA tolerance, further pre-treatment processes to eliminate chlorine are required.

Membrane Characteristics in Desalination Plants

Membranes are often classed as isotropic or anisotropic. Isotropic membranes have the same composition and physical properties across their whole cross-section. Anisotropic membranes have layers that differ in structure and/or chemical composition and are non-uniform across the membrane cross-section.

The polymer precipitates to create the membrane when it comes into contact with water. The track-etched membrane is another sort of microporous membrane. This membrane is made by bombarding a polymer film with charged particles, which attacks the polymer chains and leaves behind broken molecules. After that, the damaged molecules dissolve in an etching solution, resulting in cylindrical holes, many of which are perpendicular to the membrane surface. An expanded-film membrane is a type of microporous membrane that is less prevalent. Extrusion and stretching generate gaps in expanded film membranes, which are oriented crystalline polymers.

What can we offer?

Netsol Water, is a well-known water and wastewater management company based in Greater Noida, India. We offer a variety of water and wastewater treatment services throughout India, utilizing the most up-to-date equipment and advanced technologies.

We provide innovative RO Plant services, Water Softeners, sewage treatment plant design, effluent recycling treatment, and a variety of other services. Our water and wastewater treatment systems are highly effective at removing a wide range of chemical, physical pollutants, and biological contaminants.

Call us on +91 9650608473 or contact via email at enquiry@netsolwater.comfor more information.