Top Sewage Treatment Plant Manufacturer in Noida

Noida has seen rapid industrialization and urbanization over the past two decades. This has led to a massive strain on water resources and the generation of large quantities of sewage and industrial wastewater. While Noida has several decentralized Sewage Treatment Plants (STPs) across the city, there is an urgent need for more significant capacity expansion and treatment solutions considering the rising sewage load. Moreover, the quality of sewage treatment also needs enhancement as many existing STPs do not conform to the discharge norms laid out by pollution control boards.

There are technology oriented companies providing the fascinating technologies to treat the sewage treatment Plant. Indigenous manufacturing capabilities for STP components such as bioreactors, clarifiers, aeration systems, etc., aligned to the latest techniques like Moving Bed Biofilm Reactor (MBBR), Membrane Bioreactor (MBR), and Sequential Batch Reactor (SBR) is the need of the hour.

Companies like Netsol Water, with expertise in STP turnkey solutions, including design, engineering, installation, operations and maintenance, can exploit the Noida market to cater to the vast upcoming demand while creating local employment.

About sewage treatment plant

In Noida 2-2.5 meter of water is laying down every year, that is the biggest concern for Government and Authorities to save the water.

The most important resource is water. It is widely used for both commercial and general uses, as well as for industrial applications.

Even yet, less than 2% of the water on Earth's surface is fit for human use. As a result, to meet the world's water needs, treated water must now be used as a substitute. Industries constantly use freshwater as a solvent and coolant to improve the quality of their output.

This used water can get seriously intoxicated if it is exposed to the environment directly. Industries must build a wastewater treatment plant on their property to ensure discharge laws and safety requirements are followed. Establishing a waste water treatment plant at its location helps businesses and Industries to avoid damaging the environment.

Wastewater is collected, cleaned, and released by sewage treatment plants, which offer a crucial environmental and public health service. Sewage leaks into the atmosphere and contaminates ecosystems if not adequately treated. Sewage, for instance, includes chemicals and bacteria that decompose in the water. They deplete the oxygen, fish and other aquatic species require for survival, necessitating treatment to protect the environment. The most essential function of a sewage treatment plant is to treat the sewage or wastewater to a certain standard for safe release or reuse.

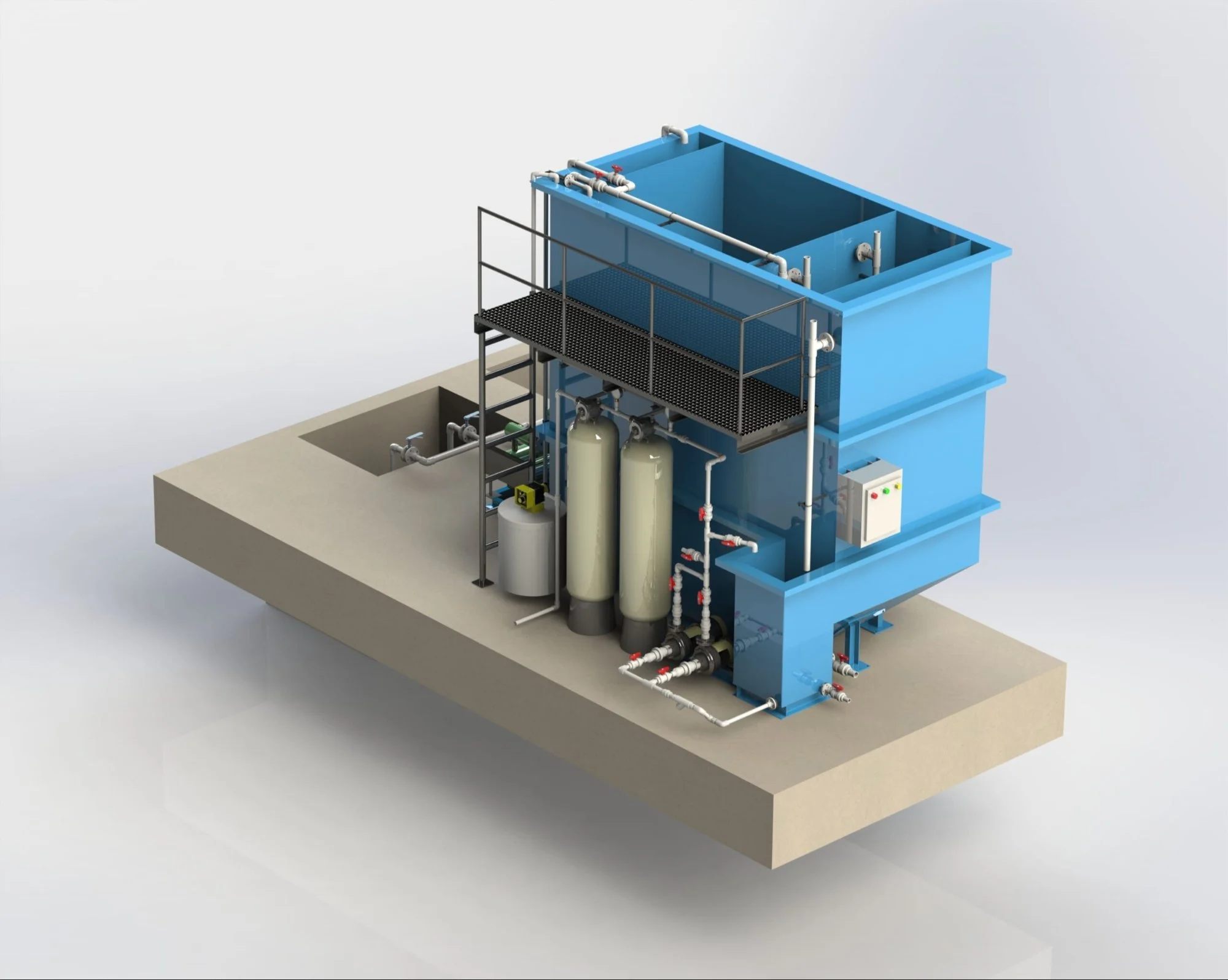

Modular sewage treatment plants (MSTPs)

Wastewater may be inexpensively treated with modular sewage treatment systems. The design's modularity makes installation and upkeep simple. They can be integrated into more extensive systems or utilized as standalone components.

Modular sewage treatment plants (MSTPs) are pre-engineered wastewater treatment systems manufactured by standardizing treatment components like tanks, bioreactors, pumps, pipes, etc, in a factory. These standardized modules are transported and installed onsite to commission a complete treatment plant. MSTPs offer flexibility to scale up operations by adding more modules as sewage flows increase at a site.

Compact modules also overcome land space constraints and enable decentralized installations near waste generation sources. Modular construction substantially reduces the time and costs of conventional civil constructed plants.

MSTPs incorporate advanced treatment technologies such as MBBR, SBR and MBR systems within compact modular units that are easy to operate with process automation. Benefits like modular expandability, rapid commissioning, compact footprint and process automation make MSTPs well-suited for clusters, small communities, institutional premises, industrial complexes and urban centers to treat their sewage efficiently. As India grapples with increasing volumes of sewage, MSTPs serve as viable decentralized solutions for diverse needs.

Resource Recovery Reuse

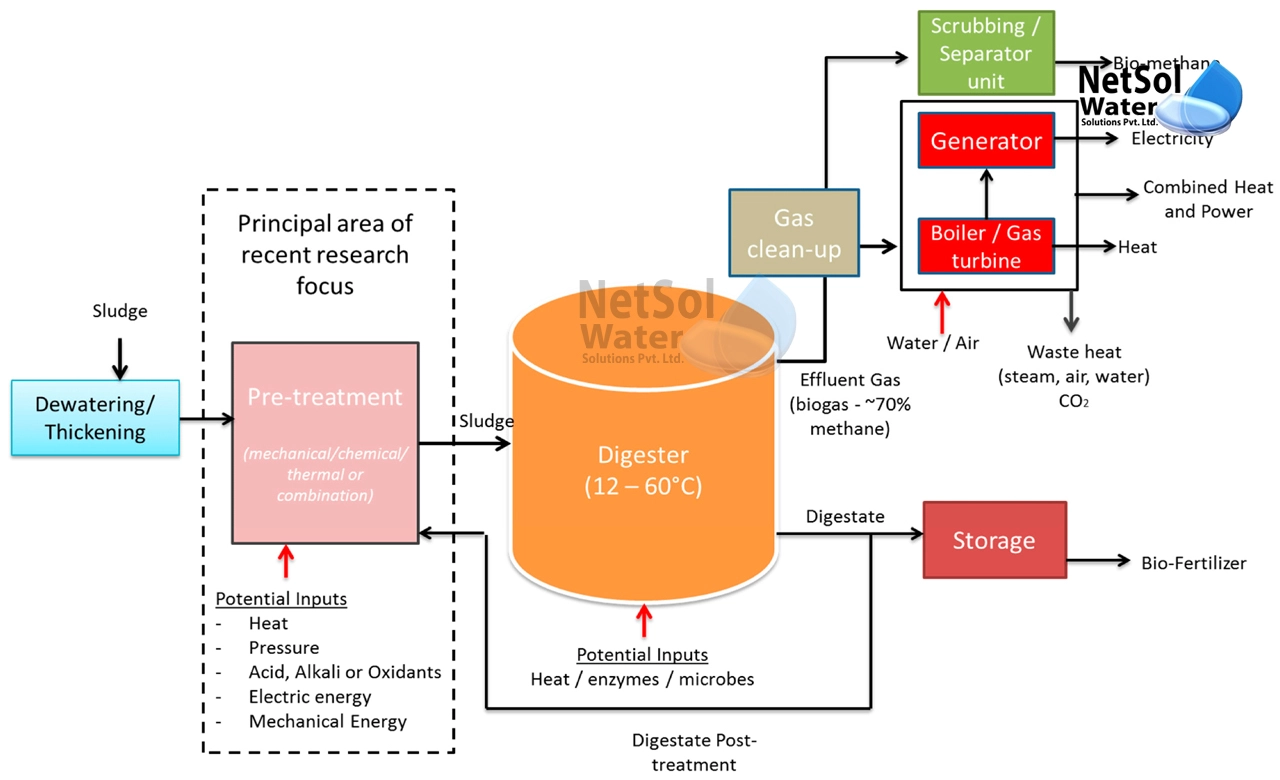

Wastewater treatment facilities should recover valuable resources from wastewater to provide value-added products like biofertilizers, renewable energy, and water for various uses. Reusing resources through creative recovery methods is a relatively new goal in wastewater treatment systems. It improves plant efficiency, lowers waste output, and has positive effects on the environment and economy. Among the most important resources that are recoverable are energy and nutrition.

Energy saving technology (Sustainable & efficient technology)

Here is an overview of the vital energy-efficient and sustainable technologies used in modern Sewage Treatment Plants (STPs):

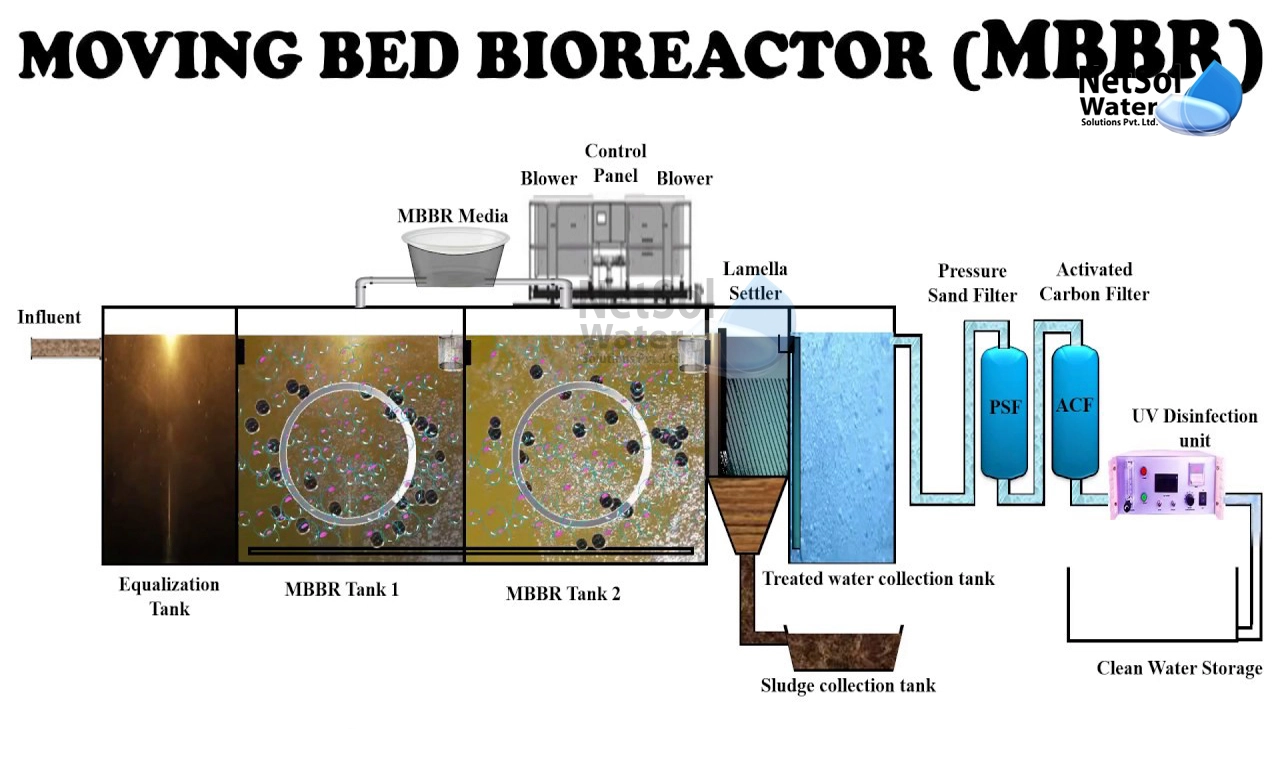

Moving Bed Biofilm Reactor (MBBR): In MBBR, the sewage and sludge flow through thousands of suspended carriers with a biofilm attached. This compact process reduces land footprint by 80% and energy consumption by 50% compared to conventional treatment methods.

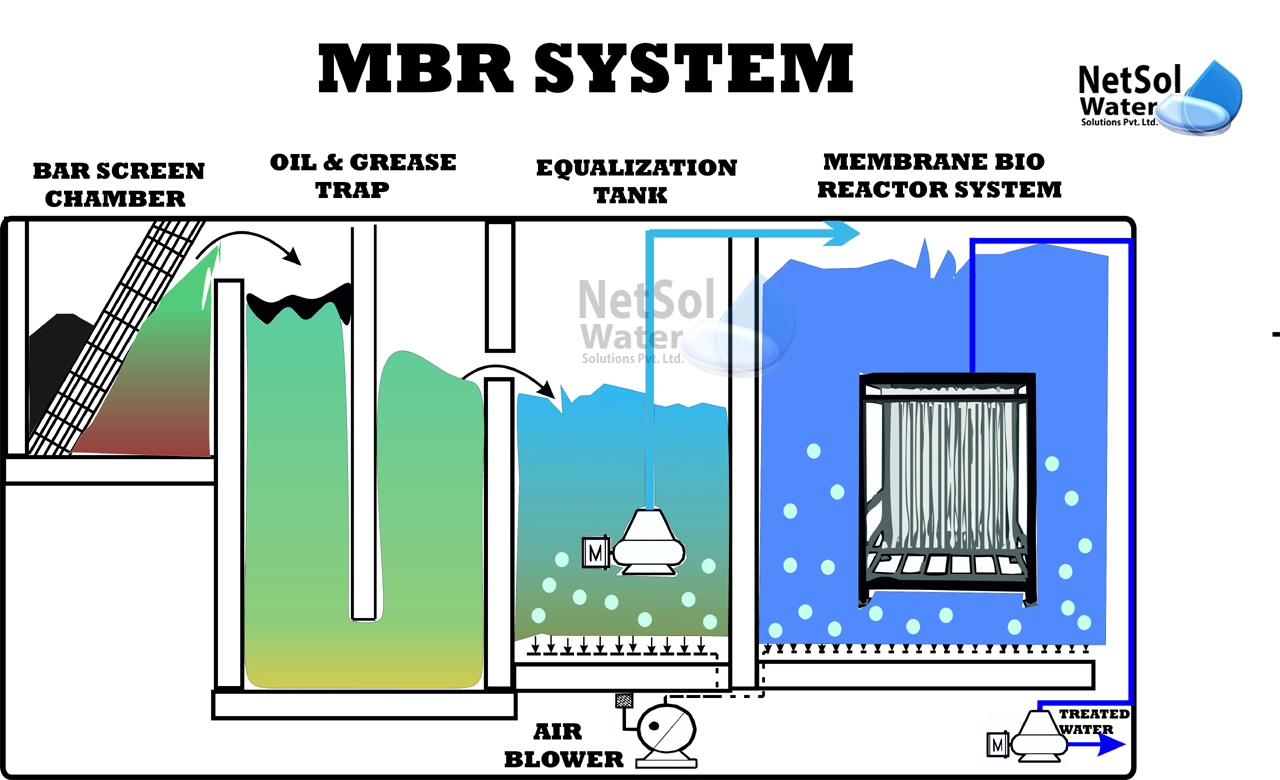

Membrane Bio-Reactor (MBR): MBR combines bioreactor technology with a membrane filtration process like ultrafiltration that eliminates the secondary clarification steps. This ensures consistent superior effluent quality, 90-99% recovery of waste input water and overall minimizes the energy expenditure.

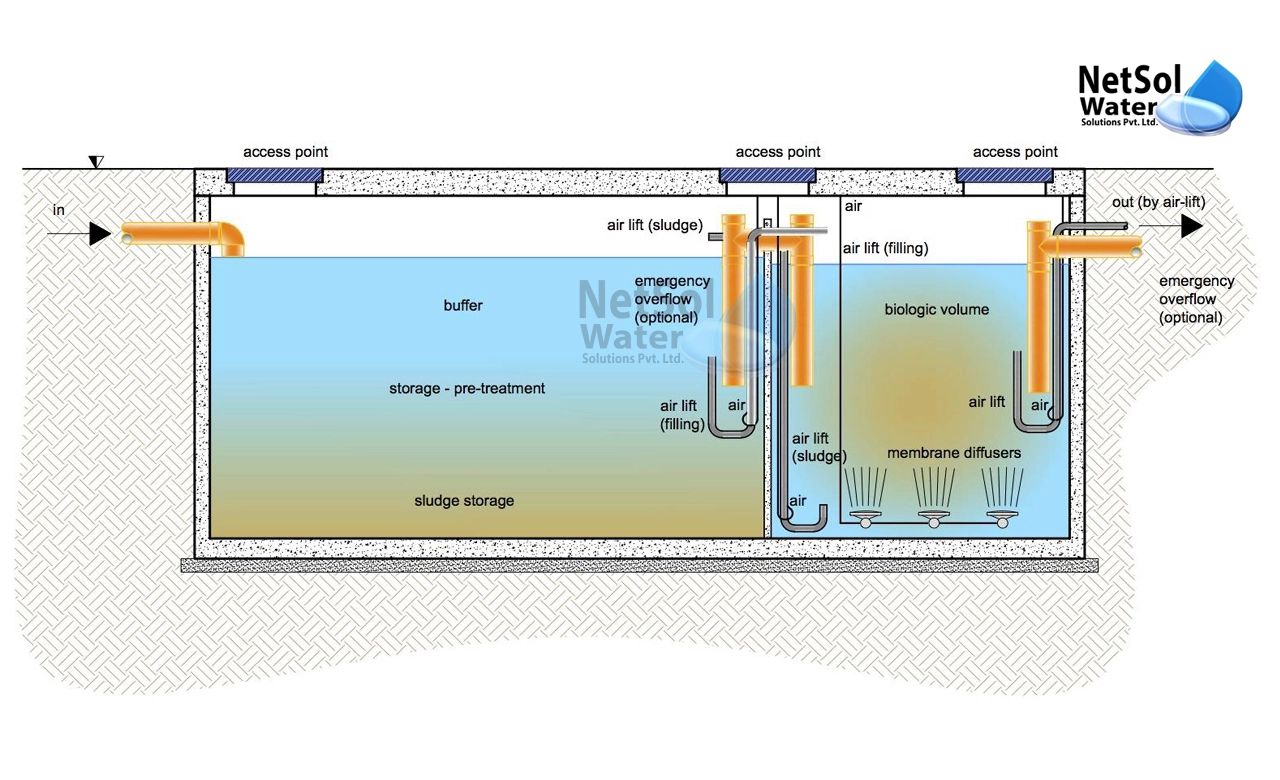

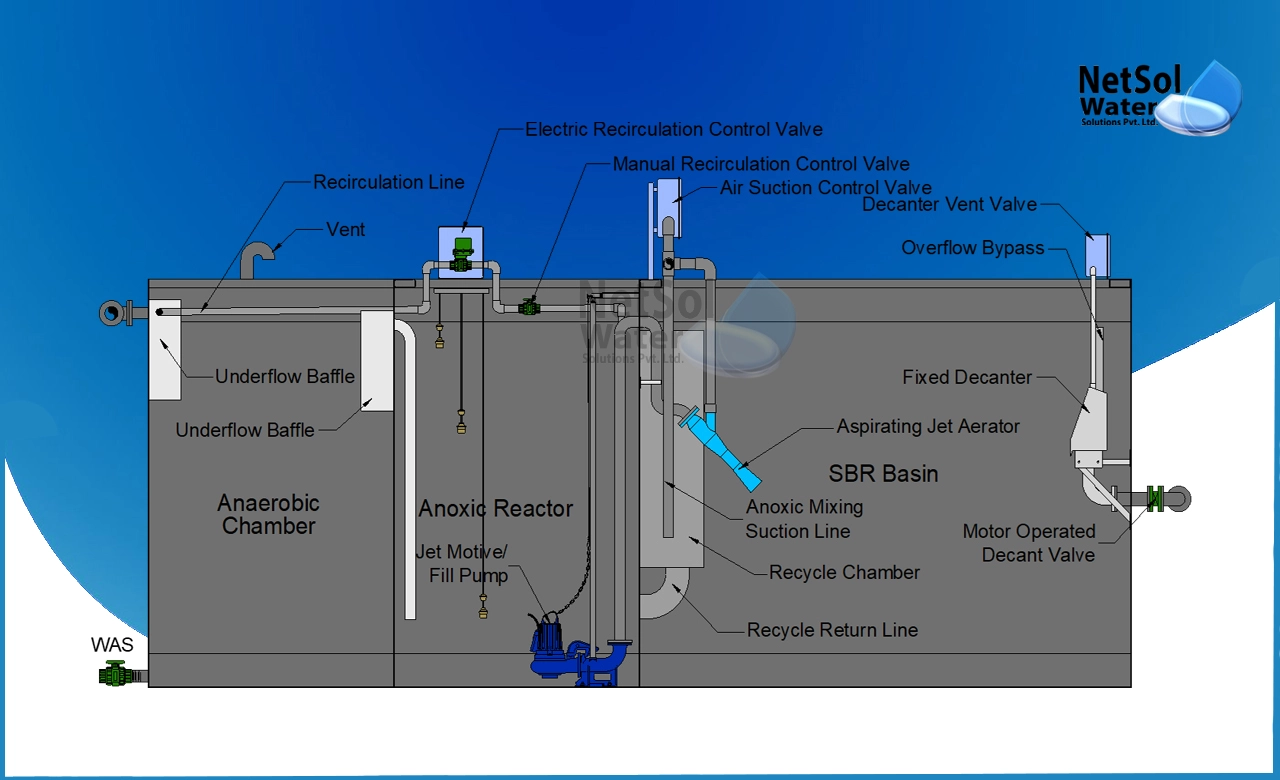

Sequential Batch Reactor (SBR): SBR allows a single tank to act as multiple tanks in sequence using timed cycles of aeration and settlement, resulting in space savings and pumping energy requirements. Advanced automation allows round-the-clock remote monitoring.

Energy Recovery from Sludge: Anaerobic digestion of sewage sludge produces biogas containing methane that can generate electricity economically to meet an STP's partial or complete energy needs, making it self-sustainable. The remaining sludge can also be incinerated at high temperatures to produce energy for in-house heating purposes, minimizing external energy usage.

Using renewable energy options like solar panels, wind turbines, and hydropower, where feasible, also reduces the overall carbon footprint of STPs.

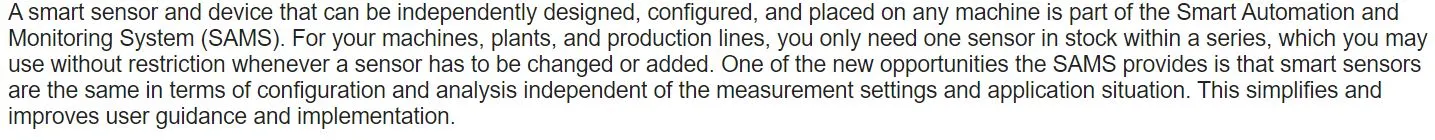

Automation and smart monitoring

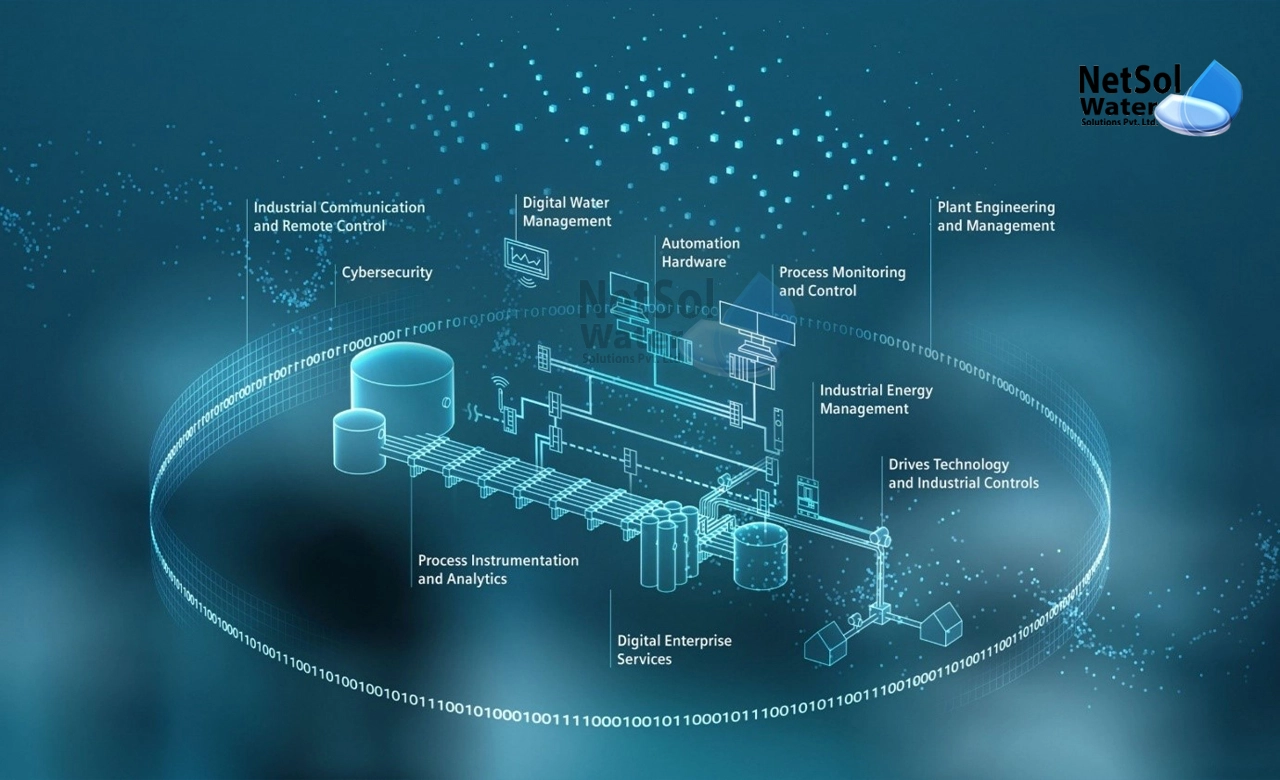

Here are some key aspects of automation and smart monitoring systems used in modern Sewage Treatment Plants (STPs):

SCADA Systems: Supervisory Control and Data Acquisition systems collect real-time data from sensors installed at critical equipment and process stages. This allows remote monitoring and control of a central control station's pumps, motors, blowers, valves, etc..

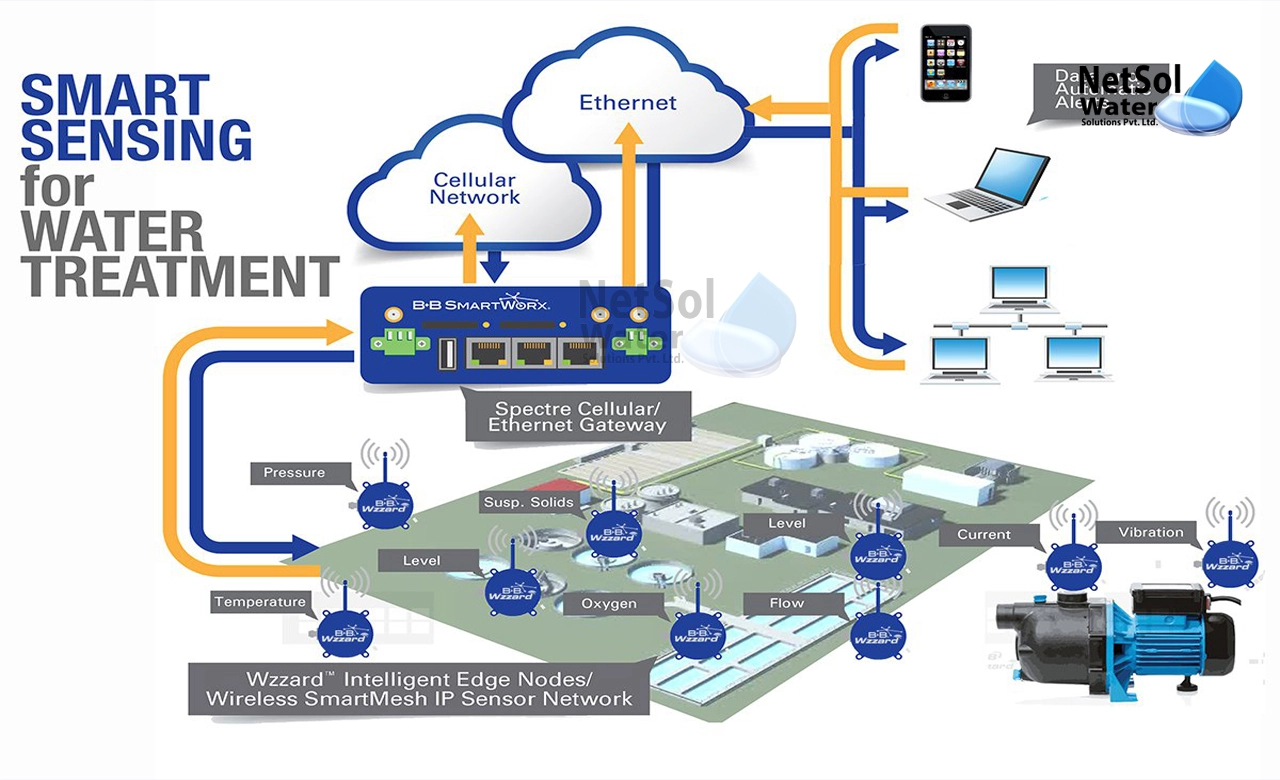

Smart Sensors: Intelligent sensors for measuring parameters like flow, pH, dissolved oxygen, etc., provide real-time insights without extensive manual sampling and testing. Automated sampling units collect samples for scheduled lab testing.

Internet-of-Things (IoT): IoT-enabled wireless sensor strategies that use cloud computing and big data analytics to provide actionable insights into plant health metrics. Data is accessible from anywhere through web dashboards and mobile apps.

Analytics & Machine Learning: Advanced AI-powered analytics on past trends and data patterns improve predictive maintenance, anomaly detection, compliance reporting and decision-making for optimal energy and process efficiency.

Programmable Logic Controllers: Automated electrical panels control electromechanical equipment through relays and timers, minimizing the need for operator intervention. Failure alerts are communicated to plant managers via text messages and email alerts.

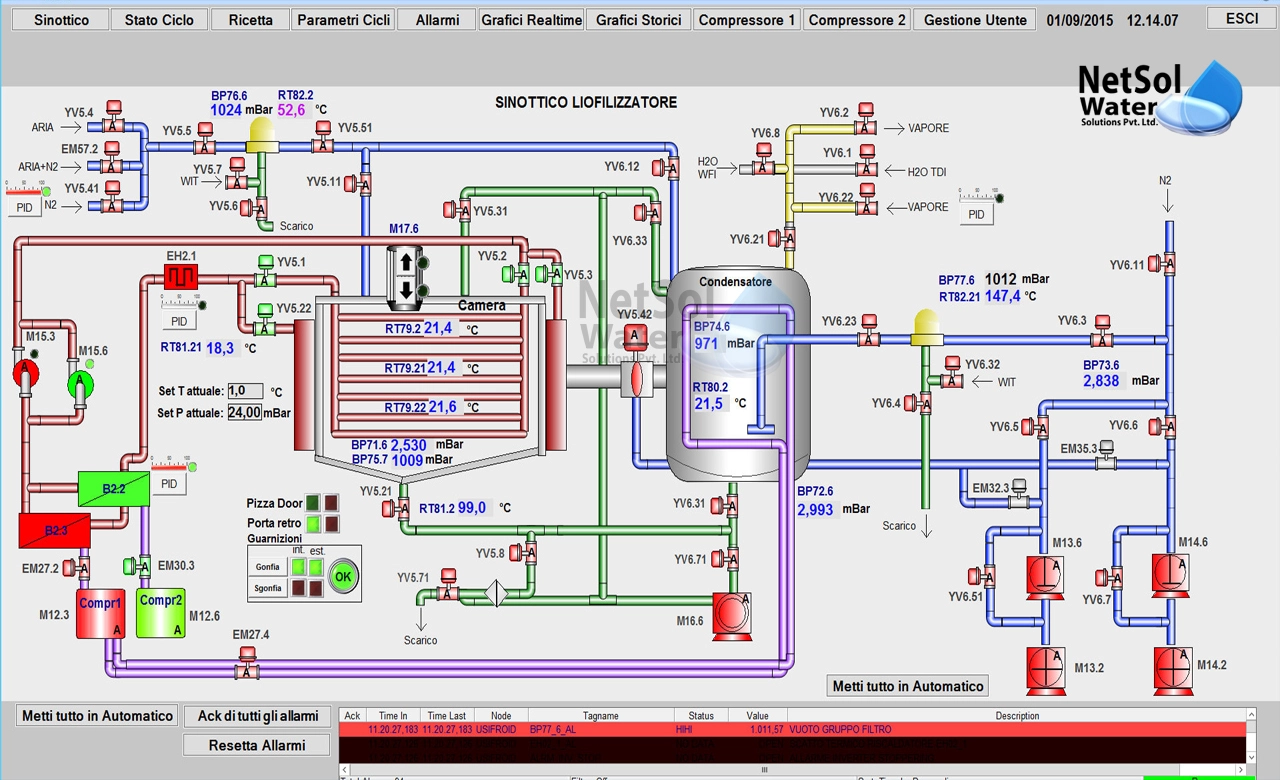

IOT (Internet of Things) for Sewage treatment plants. (Remote monitoring and management of STPs)

The Internet of Things creates a vast network of physical items by employing a variety of sensors as endpoints, allowing for widespread remote monitoring. This network in a wastewater management system enables the relevant authorities to keep a close eye on various activities in the water treatment facility. The monitoring of several water parameters, such as temperature, pressure, chemical composition, TDS, etc., is made possible via a network of diverse sensors. Automation and a centralized platform with built-in analytics may be utilized to combine this data to provide useful insights. Smart water flow meters may also measure the water flow rate across the whole treatment plant.

Ease of maintenance

Integrating IoT platforms and automation is crucial for more accessible and effective maintenance of capital-intensive STP assets. IoT allows plant managers to get timely updates on critical performance indicators even from remote locations via dashboards as data gets automatically captured and relayed from integrated sensors everywhere. Proactively tracking abnormal trends helps reduce breakdown frequency through predictive maintenance practices. Troubleshooting is also more efficient with centralized access to operating parameters spanning various equipment. Moreover, automation ensures functional processes continue uninterrupted with minimum human interference as controllers, timers and algorithms take over repetitive monitoring tasks. Operators thus focus more on the value-added resolution of newly flagged exceptions and faults. The reliance on data patterns rather than crude manual supervision for maintenance transforms STPs into automated systems. Over time, this data helps design preventative maintenance schedules optimized for specific sites. These technologies allow overcoming the specialized skill sets and high maintenance costs associated with traditional maintenance program.

Cost effective and affordable solutions

Here are some cost-effective and affordable Internet of Things (IoT) solutions that can be implemented in sewage treatment plants:

1. Remote Monitoring Sensors

Install sensors to monitor water flow, pH levels, dissolved oxygen, etc. These sensors can transmit data in real time to a cloud platform. Plant operators can access this data remotely to track performance and receive alerts about parameters outside acceptable ranges. This allows early intervention and prevents more significant problems.

2. Analytics and AI

Collect historical data from the treatment process and use analytics and AI to optimise set points for different parameters, predict maintenance needs, and identify areas for efficiency improvement. This can reduce energy and chemical consumption.

3. Automation

Use IoT-enabled actuators and controllers to automate mechanical processes like pumping, aeration, chemical dosing, etc. This optimizes equipment usage and reduces labour costs.

4. Smart Meters

Install innovative power and water meters to track usage accurately. This data can be analyzed to detect anomalies and identify issues leading to higher consumption. Reducing consumption leads to significant cost savings.

5. Remote Troubleshooting

Use augmented reality-based solutions to allow remote experts to ‘see’ the equipment and diagnose issues without being physically present. This reduces downtime and does not require bringing in expensive external experts for every breakdown.

While implementing these solutions, the critical focus areas should be interoperability, cyber security, and easy integration with existing infrastructure using wired and wireless networks like LPWAN. The IoT solutions should focus on connectivity, data utilization, and automation to drive affordability.

Meeting stringent regulatory requirements.

Sewage treatment plants face immense challenges meeting increasingly stringent regulatory standards for treated effluent discharge. With outdated equipment and manual reporting processes, many plants consistently struggle to comply with quality guidelines and submission timelines. This exposes them to penalties, suspended operations and other risks. An affordable way to address these challenges is by incorporating Internet of Things (IoT) technologies that enable real-time monitoring, automation and remote system oversight

Here are some ways Internet of Things (IoT) can help sewage treatment plants meet stringent regulatory requirements:

Continuous Monitoring and Recording

IoT-enabled sensors and meters can continuously monitor parameters like biochemical oxygen demand (BOD), chemical oxygen demand (COD), total suspended solids (TSS), as well as pH, dissolved oxygen, flow rate, etc. All this data can be recorded and validated against regulatory standards. Any exceedances can trigger alerts for timely corrective actions.

Automated Reporting and Record-keeping

The data collected from sensors can be transmitted directly to regulatory agencies to showcase compliance. This allows transparency and credibility regarding meeting discharge standards. IoT dashboards can also automatically generate reports for record-keeping and submitting compliance reports.

Optimized Processes and Quality Control

IoT devices allow control and optimization of treatment processes like aeration, clarification, disinfection, etc. This results in optimal plant performance within permitted limits. IoT enables automation and also improves the reliability of mechanical systems. Both factors enhance overall quality control.

Remote System Oversight

Regulators can be provided access to real-time IoT dashboards related to STP processes and performance management. This allows them better insights for quicker approvals and oversight. It also builds further trust and transparency between operators and governing bodies.

With continuous monitoring, data recording capabilities and driving process optimization, an IoT-enabled STP can showcase improved compliance to regulatory bodies while reducing the effort required for reporting and submissions. This is beneficial for both plant owners and environmental agencies.

Government and private sector participation

Effective adoption of IoT in STPs requires collaboration between local governments who own these assets, technology partners who provide solutions, and private operators who manage facilities. The government is promoting innovation in STPs by updating tender guidelines to encourage automation and real-time monitoring and emphasise technology integration for new plants. They are also launching innovative city challenges by inviting IoT companies to undertake pilot studies, validating reliability and cost benefits. Operators with performance-linked contracts can be mandated to incorporate sensor-based intelligence over phases in existing STPs. Government is funding these initiatives through grants while assuring a return on investment for private partners via direct incentives or long-term concessions. Large industrial groups with Corporate Social Responsibility programs can also contribute by subsidising IoT adoption to improve environmental compliance. Via well-planned partnerships across sectors, investments in IoT solutions can be promoted to enhance sewage management practices through transparent performance tracking and data-based decision-making.

The key lies in governments creating conducive policies, operators focusing on process improvements through technology and solution providers customizing innovations aligned to regulatory objectives. This drives swift, affordable and effective IoT proliferation in Sewage Treatment Plants.

Technology of sewage treatment plant in details and reasons to choose them.

Sewage treatment is vital in urban and rural areas to protect public health and ecosystem quality. Sewage treatment plants (STPs) aim to process the incoming wastewater from households and industries to remove solids, organics, nutrients, pathogens, and other pollutants before discharging or reusing the treated effluent into the environment.

Choosing the appropriate technologies and treatment solutions for an STP is critical to meet the inlet sewage characteristics, intended discharge standards, costs and reliability criteria. Let’s look at some commonly used STP technologies and the reasons for selecting them.

Preliminary Treatment

Preliminary treatment is the first stage and includes coarse screening to remove large floating objects like rags, plastics, etc. Screens typically have bar spacing of 6-75mm and can be manually or mechanically cleaned. After screening, grit removal takes place to settle denser inorganic particles like sand through velocity reduction. This protects downstream equipment from abrasion or accumulation. Preliminary units are necessary as primary treatment components in all STPs.

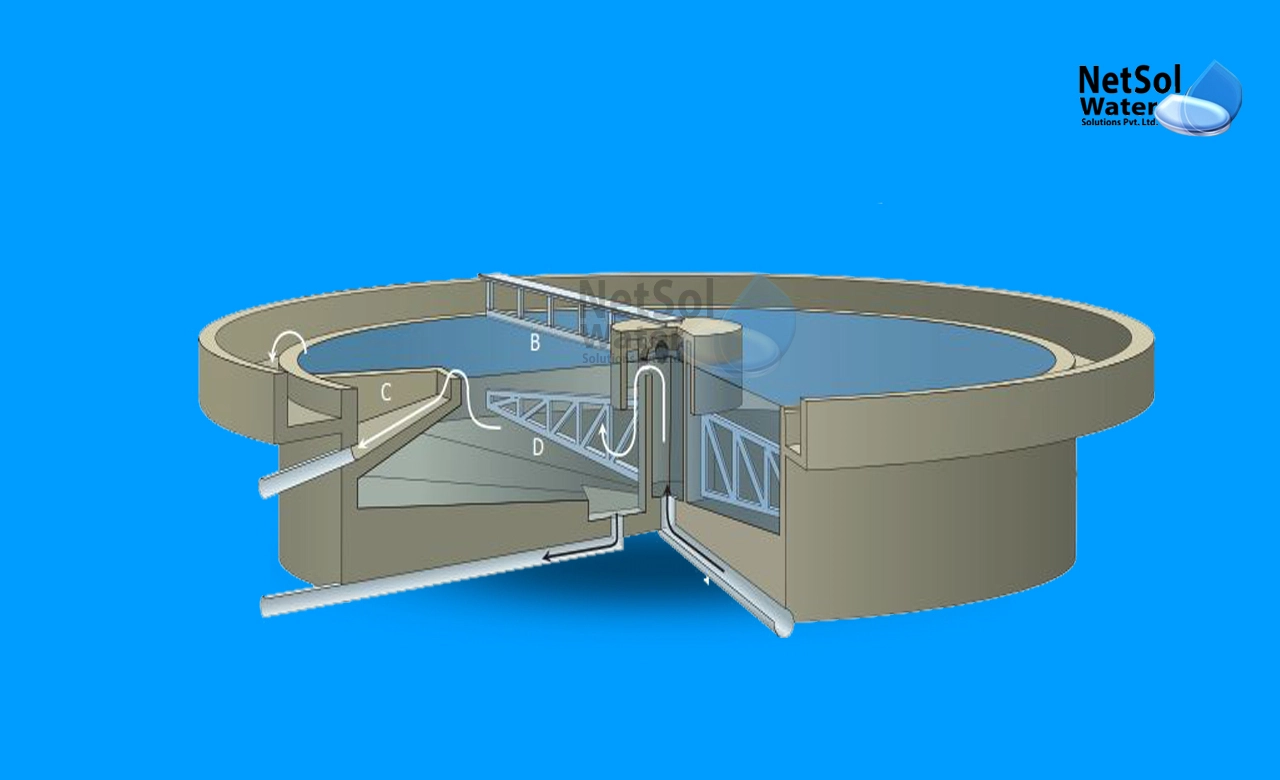

Primary Sedimentation

Settling or sedimentation tanks facilitate the removal of suspended particles through gravity settling. Such primary clarifiers can achieve a 50-70% reduction in TSS and a 25-40% reduction in BOD. Rectangular tanks have mechanical sludge collection, while circular tanks use rotating scrapers. Primary sedimentation improves subsequent biological treatment performance. It provides substantial organic capture with minimal energy input and simple equipment that requires low operational skills. Hence, most STPs incorporate primary clarification.

Secondary Biological Treatment

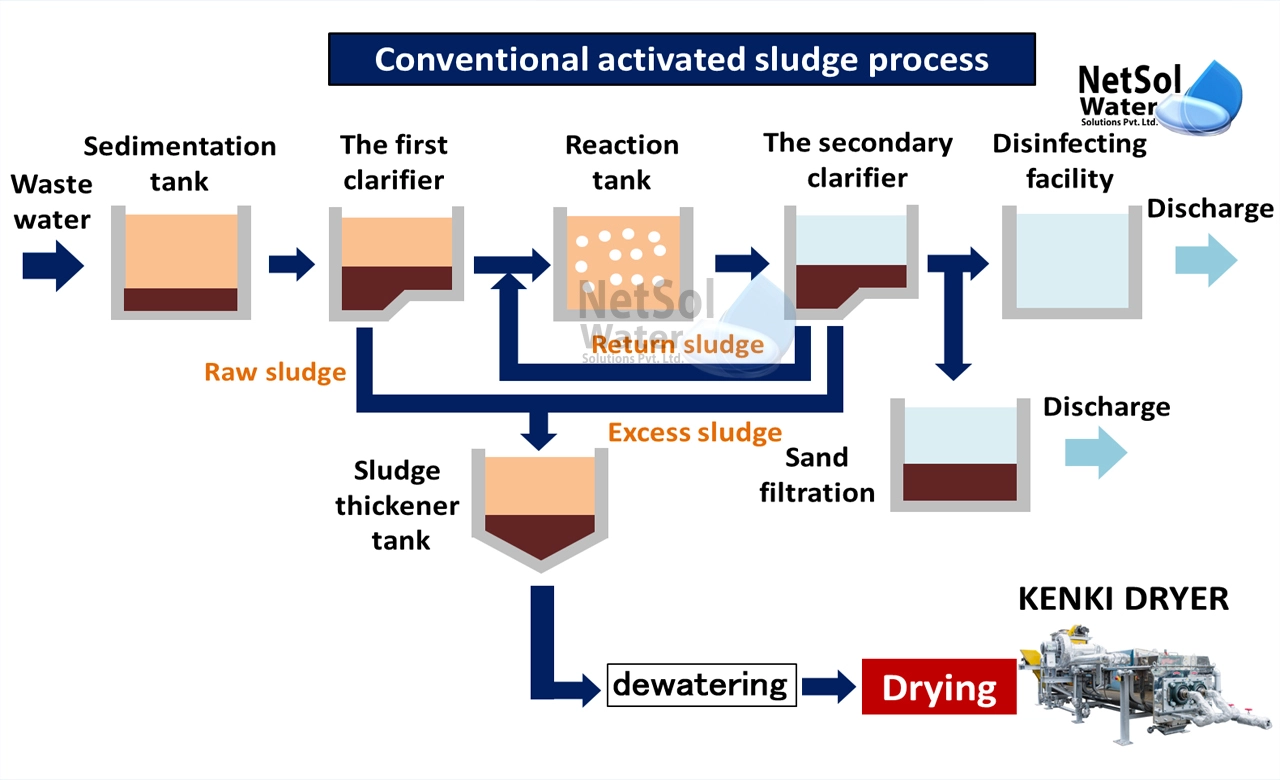

The secondary treatment stage uses microbial metabolism to oxidize organic matter. There are several technologies used in activated sludge-based biological processes:

Activated Sludge Process:

Comprises aeration tanks to bring wastewater into contact with microbial sludge under oxygen-rich conditions for aerobic digestion of organics. Followed by secondary clarifiers to separate biologically treated water from sludge flocs. It produces high-quality effluent but requires significant power for aeration.

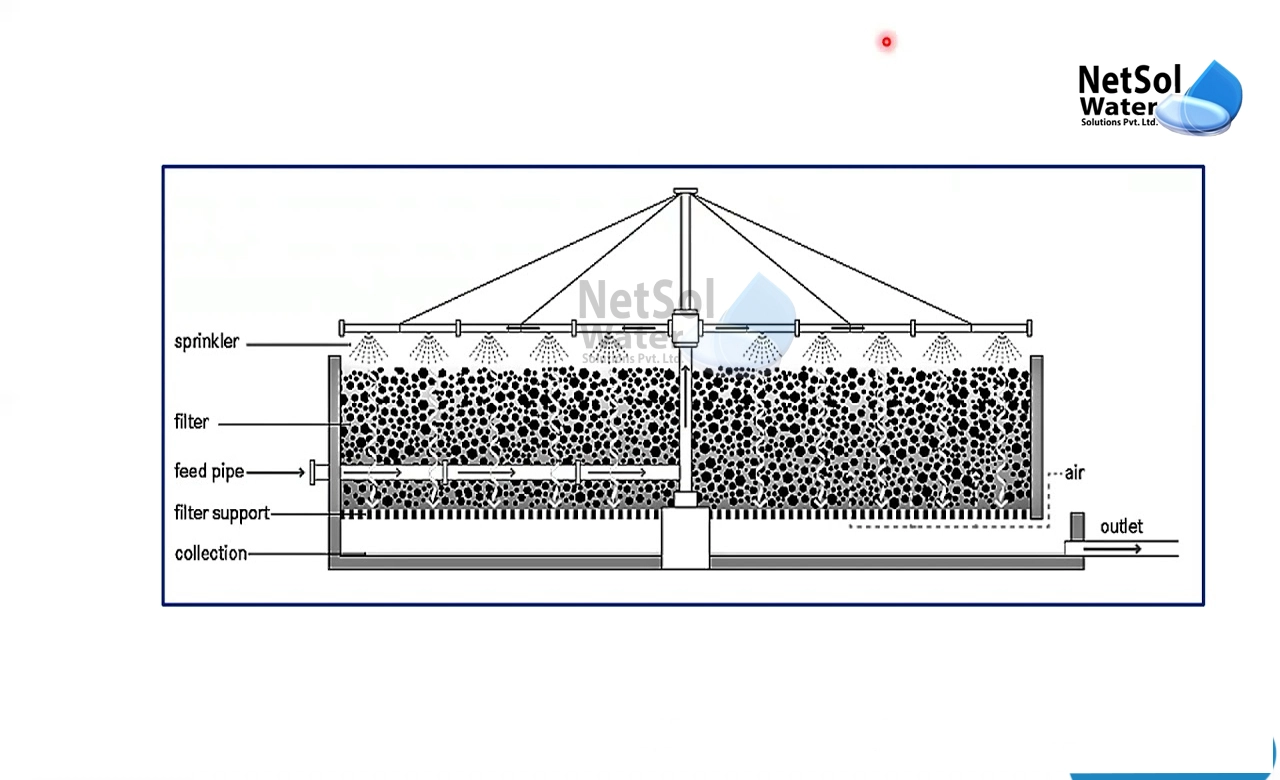

Trickling Filters:

Wastewater is passed through a bed of rock, gravel or other media on which biofilm grows. Aerobic degradation happens on the media surface without needing sludge recirculation. Requires large filter areas but less electricity.

Sequence Batch Reactors (SBRs):

Combine equalization, aeration and clarification sequentially in timed cycles in the same tank using suspended microbial growth. Compact, automated, and require less land than conventional systems.

The activated sludge process is versatile and widely used for organic solid nutrient removal across varying flows. Trickling filters suit small communities lacking energy access. SBRs are chosen for small decentralized plants with land constraints or expansion needs.

Additional Treatment Stages

Tertiary or advanced treatment can be added based on discharge criteria or water reuse needs:

Filtration using sand filters, micro filters or membrane bioreactors

Adsorption through activated carbon to remove residual organics

Disinfection using chlorine, UV radiation to kill pathogens

Nutrient removal through chemical dosing or constructed wetlands

Such systems tackle specific contaminants like nitrogen, phosphorus, bacteria, and viruses and assist in producing recycled water.

Why should you choose Netsol Water for your Sewage Treatment Plant manufacturer Partner

Every sewage treatment plant has the same essential components, but each has a distinct utility, varying depending on usage and necessity. As a result, it's critical to select the appropriate STP plant to match your needs. Sewage treatment plants form a complex array of mechanical, electrical and biological unit processes working synergistically to treat millions of liters of wastewater every day across India’s urban centers.

Choosing the right STP technology and reliable regional manufacturer as a plant owner carries significant weight, ultimately impacting compliance, operations and maintenance costs over decades.

As large municipal tenders float globally, opting for a trusted local company like Netsol Water brings innate advantages from concepts to commissioning. Local companies understand local challenges better - seasonal variation in sewage quality and quantity, availability of trained plant operators, regular power outages requiring backup systems, procuring spare parts, supporting AMCs, etc. Leveraging field expertise, Netsol can customize technical designs that suit regional needs rather than adopt templates global designs.

Secondly, established companies have amassed rich reference sites across neighboring cities. Visiting such plants provides tangible confidence in process performance, construction quality, longevity, aesthetics, and meeting client expectations. Interacting directly with their existing clients is the best testimonial before committing significant Capex investments.

Third, seamless communication and prompt issue resolution come naturally when engaging a consultant or contractor speaking the same language, accessible locally when required rather than overseas suppliers with significant time lags. Logistics and transportation also become more accessible for large equipment modules.

While one can argue about marginal savings sourcing STPs internationally owing to material costs, losing out on the above intangible aspects often outweighs such benefits.

Evaluating vendors holistically on technical expertise, service quality, track record and understanding local dynamics is vital. Hence, going vernacular with companies like Netsol Water, based in Pan India for over the last 20 years, is the most prudent choice for sewage treatment plants. Their portfolio of many successful STP projects across 100 + states shows the trust domestic clients have vested in their creation.

Industries required STP plants & names with details of industries we are serving in Noida

Being a prime industrial hub, Noida houses a range of industries that require dedicated effluent and sewage treatment facilities to meet pollution control mandates before discharging wastewater. Our company caters to varied manufacturing and commercial establishments across key sectors like:

Automotive - Automotive manufacturers like Yamaha, Honda Siel Exedy India Ltd.

Textiles - Multiple dyeing and printing units discharge high COD/colour effluents requiring tertiary treatment with activated carbon filters and ozonation.

Pharmaceuticals and Chemicals – GlaxoSmithKline, Simon India Ltd, Sun Pharma.

Food and Beverage – Rajni Gandha, Parle G, Pepsi, Haldiram, Bikanerwala

Hospitality/ Hotels – Hotels like Radisson Blu, and Crowne Plaza, Holiday Inn.

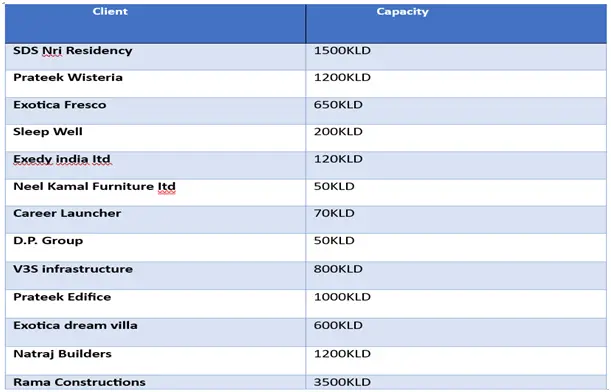

Group Housing Societies - Netsol have in stalled lots of Sewage Treatment Plants for societies like - Prateek Wisteria, Prateek Edifice, Exotica Fresco, SDS NRI Residency, Exotica Dreamville.

Hospital - M/S Netsol has already installed sewage Treatment Plant/ Effluent Treatment Plant for many reputed Hospitals in Noida .

Electronice Manufacturers - Sinsung, Haier Electric, Panasonic, LG. Hisys eng

Including - Kailash Hospital Noida, Sharda Hospital Greater Noida, PGI Medical College, BPS Medical College, Metro Hospital Noida, Bhoomanand Hospital Haridwar, Orthonowa Hospital Delhi Kailash Hospital Dehradoon, Central Paramilitary Hospital Greater Noida.

With experience across the above domains, our trained designers cater to specific industrial effluent characteristics through process sequencing and sizing of treatment units before release into municipal sewers or surface waterbodies based on pollution board norms. We also undertake O&M via annual contracts. Quality deliverables customised for industrial needs make us the preferred STP solution experts in Noida's manufacturing landscape. Netsol Water takes pride in partnering with prestigious companies and facilities in Noida by providing customised sewage and effluent treatment solutions aligned to their specific requirements. Our clientele includes renowned organizations like Kansai Nerolac Paints, Krauter Tools, Larsen and Toubro, LRiPL, and Maharishi Ayurveda Products Ltd, among many others. Following is the table along with the STP plant capacity which Netsol has successfully installefd in Noida.

Understanding the varied nature of effluent and wastewater generated from processes in paint manufacturing, engineering goods fabrication, lithium-ion battery assembly, specialised medicines production, etc., our expert team analyses key contaminant parameters and designs appropriate biological and tertiary treatment process flows leveraging technologies like activated sludge process, membrane bio-reactors, dissolved air floatation, activated carbon towers and multiple effect evaporators tailored to inlet effluent properties and desired discharge norms. With approximately 500+ installations across the country serving important industries, Netsol understands the critical needs of the manufacturing sector related to meeting stringent environmental compliance, which serves as the foundation for all our treatment system designs and project executions.

Case Study: Most Demanding STP plant- based on type, capacity & technology in detail

Here is a detailed case study on the 20 KLD sewage treatment plant based on MBBR technology installed by Netsol Water for Jubilant Byosis in Noida:

About the Facility

Jubilant Byosisis the leading R&D company for Pharmaceutical companies in the world As part of its expansion in whole India. They needs Sewage Treatment Plant and Effluent Treatment plant for their R&D Lab and Noida and in Greater Noida.

Existing Challenges

Jubilant Byosisis faced challenges initially when trying out conventional sewage treatment technology options. Issues like space constraints within urban restaurant plots, poor sludge settleability in two-stage systems, and occasional odour issues meant common choices like activated sludge process STPs were not quite feasible. Being located in Noida, a critical commercial hub witnessing massive real estate growth, the availability of open land parcels that could house extensive treatment infrastructure was also a roadblock. A compact, decentralised plug-and-play system demanding minimal maintenance and operator intervention was needed.

Selected Technology

After evaluating modular STP proposals from various established vendors, Jubilant finalised a containerised MBR-based sewage treatment plant with a 20 KLD operational capacity offered by Netsol Water. The automated, compact structure and process reliability offered by MBBR technology meant that a minimal land footprint would be adequate within the plot. Jubilant Byosis now uses this system to successfully treat all wastewater generated from this Noida pizza outlet before reusing treated sewage for site applications. Compliance benefits and corporate image enhancement represent welcome outcomes.

Working Principle

The sewage treatment system from Netsol Water leverages advanced MBBR technology to treat the wastewater streams reliably with fluctuating loads coming from various sections of this pizza outlet. Structured HDPE biofilm carriers exhibiting high specific surface area are used within the MBBR reactor tank. These carriers tumble within the sewage flow, allowing specialised microbes to attach to their surfaces as films and colonies. This enables excellent organic degradation and ease of biomass separation without needing any internal recirculation units. Alongside the MBBR basin, the plug-and-play plant houses integrated screening, equalisation and disinfection stages within a compact footprint to deliver treated sewage that meets the end usage environment guidelines. Automated controls for aeration, pumping, instrumentation and analytics allow remote monitoring from a central location, thereby minimising intensive manual supervision onsite. Such well-engineered decentralised systems incorporating the MBBR process can thus sustainably service urban localised sewage treatment needs while occupying minimum space.

Key outcomes

The application of a decentralized MBBR-based sewage treatment solution by Jubilant Byosis Ltd. how customised process configurations and wise technology choices can allow responsible management of wastewater from space-constrained urban commercial establishments. This aids overall sustainability and enables harmony between expanding business footprints and environmental impact mitigation requirements. This also enhances Jubilant Byosis Limited's eco-friendly corporate image among its growing customer base.

Capacity and CPCB/UPPCB norms for STP in Noida

Wastewater generated by a community of people is known as sewage, sometimes domestic or municipal wastewater. Its defining characteristics are its bacteriological status, physical state, chemical and toxic composition, and flow volume or rate. An assessment of the amount of sewage generated is required to guarantee appropriate sewage collection, transportation, treatment, disposal, and reuse.

The Central Pollution Control Board (CPCB), with assistance from State Pollution Control Boards / Pollution Control Committees and Local Bodies, periodically assesses the amounts of sewage produced and its treatment. Information about water supply, sewage generation, and treatment capacity is gathered by distributing questionnaires to the relevant parties. The most fundamental, independent, and essential element influencing estimates of sewage volume, sewer network size, and sewage treatment capacity is population. Status reports are created using the data that local authorities provide.

The Uttar Pradesh Pollution Control Board (UPPCB) has established that at least 80% of the sewage generated in major cities should be treated before disposal/reuse. For Noida, the body has stipulated that at least 80% of the 285 MLD sewage generated needs to be treated. As per official data, Noida does meet the UPPCB's 80% sewage treatment norm. The current operational capacity corresponds to around 79% of treatment levels. However, there are concerns that more capacity will need to be added as the population grows.

Being an industrial zone, Noida houses hundreds of small, medium and oversized sewage treatment plants across industrial sectors, commercial buildings and residential apartments. As per UPPCB guidelines, any facility generating sewage over 100 KLD requires an on-premise STP to treat it before discharging it into municipal sewer lines. The treatment technology and capacity depend on sewage quantities, quality and intended reuse, if applicable. For example, a 25,000 LPD plant would suffice for a small 100-unit apartment complex, while mega townships require 5-10 MLD scale installations. The norm for treated BOD levels is less than 20 mg/l for final discharge. Certain zones stipulate advanced tertiary treatment to reuse levels of 10 mg/l BOD, <1 mg/l phosphorus and 10,000 coliform counts for applications like flushing, gardening, etc. This explains the growing number of compact containerised EA-ASP-based SBRs and large-capacity membrane bioreactor systems installed across Noida, matching demands and regulatory obligations.

Contact Netsol Water for consultancy/installation of sewage treatment plants.

Selecting the optimum sewage treatment plant technology and capacity aligned with your needs and regulatory norms could seem overwhelming initially, considering the technical complexities involved. However, by following a structured methodology focused on key wastewater characteristics and intended quality objectives, our expert consultants at Netsol Water can guide you through seamlessly configuring the ideal STP for your facility.

About Netsol Water & sewage treatment plant manufacturer in Noida

Netsol Water is an emerging company specialising in designing, building, installing, and maintaining wastewater and effluent treatment plants across India. Netsol has successfully installed many sewage treatment plants (STPs) and effluent treatment plants (ETPs) for a diverse clientele comprising residential apartments, hotels, hospitals, commercial buildings, and industries.

With a growing expertise spanning over a decade, Netsol employs the latest technologies in water treatment, such as Moving Bed Biofilm Reactor (MBBR), Sequential Batch Reactor (SBR), Membrane Bioreactor (MBR), Ultra Filtration, and Reverse Osmosis. Besides STP and ETP plant set-up, Netsol also offers upgrades, operations & maintenance services, ensuring optimal performance and statutory compliance. The in-house design and engineering team is focused on delivering customised, cost-effective solutions catering to the specific wastewater treatment needs of the client.

Our proven selection framework focuses on:

1- Understanding wastewater generation patterns – sources, peak flows, seasonal variations etc.

2- Analyzing influent quality covering parameters like BOD, COD, TSS, nutrients, salinity etc.

3- Defining treated sewage standards expected for discharge/reuse applications.

4- Detailed water balance, including options to reduce, recover or recycle.

5- Land space, capital costs and O&M budgets allotted for the STP

With clarity on the above points, our in-house design team can develop an appropriate treatment scheme matched to your scenario, considering aspects like process sequencing, hydraulic sizing, equipment capacity and O&M impacts for reliable operations. Technology choices span conventional, compact, decentralised and zero-liquid discharge configurations.

With over 500 installations across 20 states serving residential apartments, office spaces, townships, hotels, hospitals and industrial units, Netsol Water has unmatched expertise as your dependable STP partner from conceptualisation to commissioning.

To get started, please contact our water treatment experts on:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com