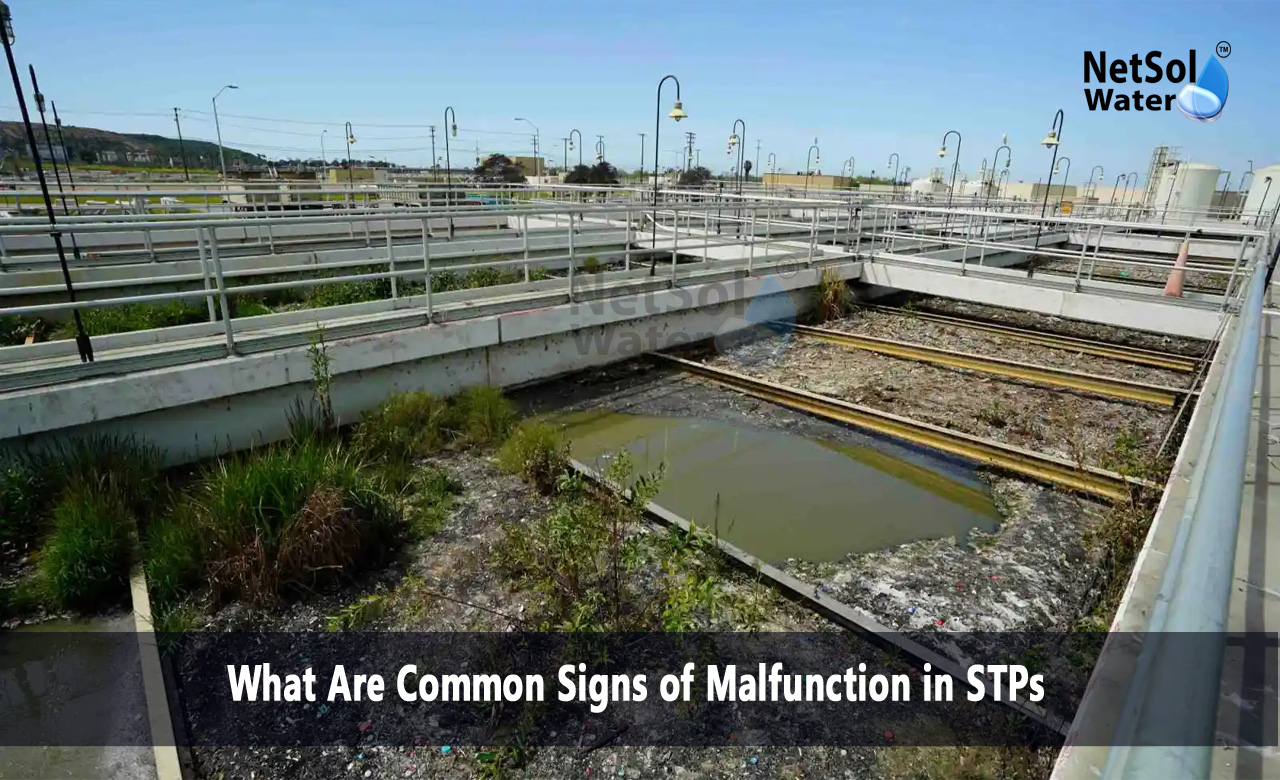

What Are Common Signs of Malfunction in STP Plant?

A working STP saves resources and keeps water clean. Yet even the best STPs can show early warning signs of trouble. Recognizing these signals can prevent breakdowns and reduce costs. In this blog, we describe common signs of malfunction in STPs. We explain why each sign matters and how it affects plant performance. By spotting issues early you can act quickly. Netsol Water supports clients at every step so plants run smoothly and safely. Netsol Water stands as a leading manufacturer of Sewage Treatment Plants or STPs. We design systems that treat wastewater with care. We help industries protect the environment and meet standards

Unusual Odour Emission

A clear sign of STP trouble lies in strange smells around the site. Foul odours can harm local air quality. They may stem from untreated sewage or biological imbalance in reactors. Let us have a look at some key warnings that hint at odour problems.

Anaerobic Conditions

When bacteria lack oxygen in treatment tanks they produce hydrogen sulfide. This gas emits a rotten egg scent. You may notice these odours near aeration zones. The smell grows stronger if air supply fails or mixers break. Fixing blowers or cleaning diffusers restores airflow and cuts odour.

Sludge Build-Up

Excess solids in clarifiers force sludge to rise. This trapped matter decays and gives off a bad smell. You might see floating scum on the water surface. Removing sludge by scraping or sludge withdrawal stops odours. Regular cleaning keeps the tank clean and odour-free.

Poor Effluent Quality

Effluent quality shows plant health. Clear water leaving the unit marks correct operation. If treated water looks cloudy or carries solids you face a defect. Let us have a look at some signs that signal effluent issues.

High Turbidity

When water still holds particles it appears murky. Lab results show high turbidity values. Cloudy water can harm downstream processes. You must check clarifier settings and filter media. Adjusting flocculant dosing or backwashing filters brings clarity back.

Elevated Nutrient Levels

Nitrogen and phosphorus must drop to safe levels before discharge. If test results show high nutrient counts you breach regulations. Overly long hydraulic loading or dead zones in reactors can cause this. Balancing flow rates and keeping biomass healthy lowers nutrient loads.

Excess Sludge Accumulation

Sludge holds solids removed from wastewater. You must remove it at regular intervals. When the tank holds too much sludge plants lose capacity and performance. Let us have a look at some warnings that point to sludge trouble.

Rising Sludge Blanket

A normal sludge blanket stays low in the clarifier. When it climbs you lose clarity in the treated water. High blanket levels signal poor settling. You can thin the sludge by taking it out or by adding a sludge digester. This keeps the tank volume free for new flow.

Sludge Bulking

Sometimes sludge does not settle well. Flocs remain fluffy and resist compression. This bulking makes solids pass into the outflow. Checking bacterial health and adjusting nutrient ratios cures bulking. Healthy flocculation restores good settling.

Equipment Noise and Vibration

Smooth plant parts do not make loud noise or shake excessively. Strange sounds warn of failing parts or imbalance. Let us have a look at some clues that flag mechanical issues.

Bearing Wear

Worn bearings in pumps and motors grow noisy or hot to the touch. You may hear grinding or feel vibration. Ignoring this can lead to pump failure or shaft breakage. You must lubricate parts and replace old bearings as needed.

Misaligned Shafts

When pumps or mixers sit out of line the system shakes. You feel vibration along the pipe runs. This stress may crack connections and cause leaks. Realigning shafts and tightening mounts restores calm operation.

Electrical Fault Alarms

Modern STPs trigger alarms when sensors detect odd electrical draw or faults. If panel lights blink or trip repeatedly the motor control may fail. You must inspect wiring and test control units. Repairing or upgrading these parts stops the alarms.

Conclusion

Netsol Water knows the common signs of malfunction in STPs and helps clients act fast. We design plants that last and guide you through early issue detection. If you face odd smells, poor water quality, too much sludge or strange machine noise reach out to us. We will review your system and provide expert support. Contact Netsol Water today for more information or to request a consultation on your STP needs.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com