Hard water can lead to a slew of major issues. Limescale can form in water containing dissolved calcium and magnesium ions, impairing and damaging industrial equipment’s like heat exchangers. Furthermore, the presence of these ions lowers soap's lathering power and overall effectiveness, resulting in poor wash water. Water softening is a technique for dealing with hard water.

Water softening commonly employs ion exchange technology. An exchange medium is used in the procedure to replace detrimental ions with more acceptable ions. The ion exchange unit must go into recharge mode to renew the medium as it becomes saturated with the ions taken from the hard water. To reverse the ion exchange process, a highly concentrated solution of desired ions must be passed over the medium during the recharging process. The ion exchanger can be turned back on once it has been refilled.

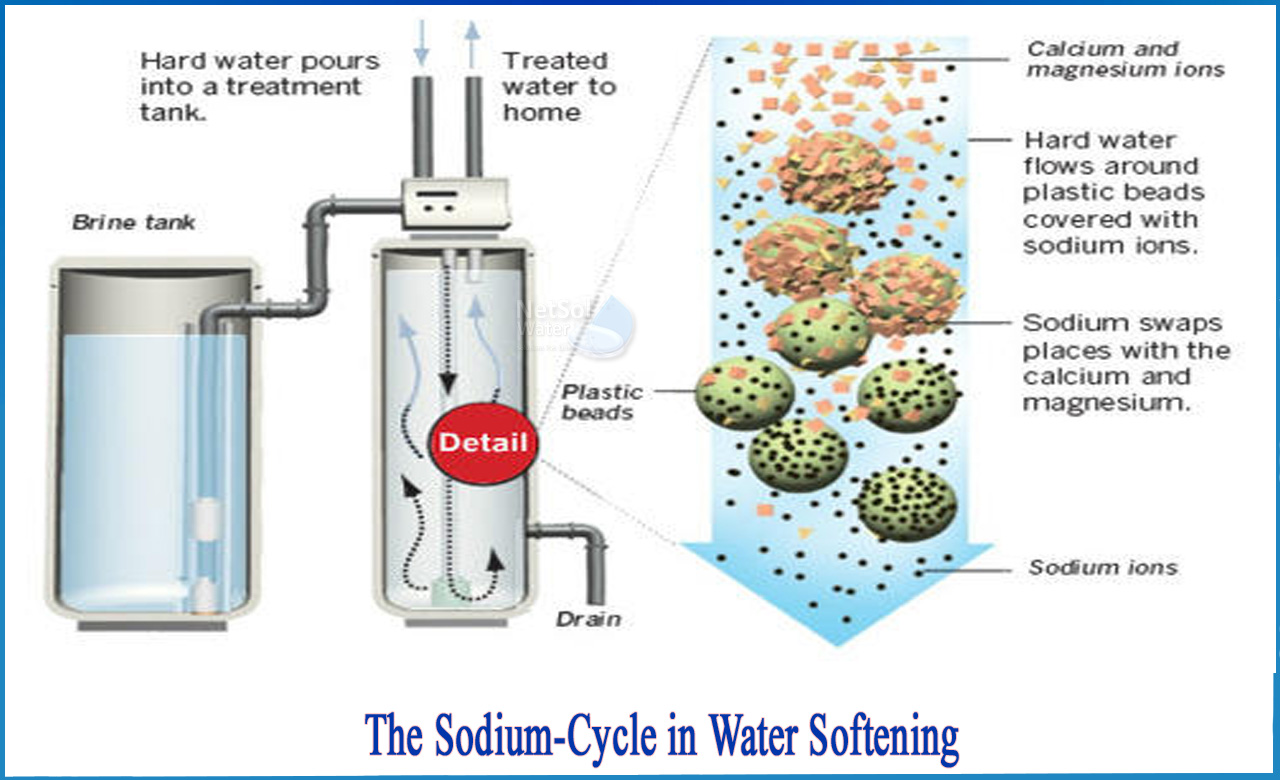

How to Water Softening work with Sodium-Cycle?

Sodium-cycle softening is the most extensively utilised ion exchange technique for water softening. The ion exchange medium in this method is a bed of porous beads. These beads, also known as softer resin, substitute sodium ions for calcium and magnesium ions in the water.

When the beads are saturated, they go through a regeneration cycle in which a brine is passed over them, replacing the magnesium and calcium ions with sodium ions. The regenerate fluid and rinse water are used to flush the hardness generated during the regeneration cycle.In sodium-cycle softening, there are four basic steps to the regeneration process.

>Backwash - The regeneration cycle starts with a backwash, which reverses the flow of water up through the resin to flush out the suspended solids that have accumulated on the surface. A good backwash can increase the resin bed by 50% and takes around 10 minutes to complete. When the water starts to run clear, the backwash cycle is over.

>Brine Draw - Following the backwash, a brine solution with an approximate concentration of 8-12 percent is sprayed on top of the resin bed for about 20 minutes. The high sodium ion concentration in the brine causes the hardness of the resin beads to be eliminated and replaced by sodium ions. At a flow rate of 0.5 to 1.0 gallons per minute per cubic foot, the brine draw is most effective.

>Slow Rinse - After the brine draw is finished, the resin bed is rinsed with clean fresh water at a rate that is similar to the brine draw. The ion exchange process is now complete, and the excess brine is drained down the drain.

>Quick Rinse - A quick rinse of fresh water at a rate of 1.5 to 2.0 gallons per minute per cubic foot of resin is the final step in the regeneration process. This phase removes any remaining hardness and brine from the resin bed and takes 20 to 50 minutes.The sodium-cycle softener is ready to treat hard water once the resin bed has been regenerated.

Water softening is excellent at removing lime scale causing ions and preventing the damage that these deposits cause to equipment. When choosing a water softener, it's critical to locate the best solution for your specific needs.

For more details, consult Netsol Water!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.