Submerged Membrane Bioreactors for Industrial Effluent Treatment Plants

Industrial wastewater is a big problem as it contains lots of different pollutants, like organic matter, dirt, and sometimes toxic chemicals. Regular ways of cleaning it up are not very effective and can lead to environmental hazards and break the rules about how clean water has to be before it's released. Submerged membrane bioreactors (MBRs) are a new and hopeful solution to this problem. They're better than traditional methods in many ways.

What are Submerged Membrane Bioreactors

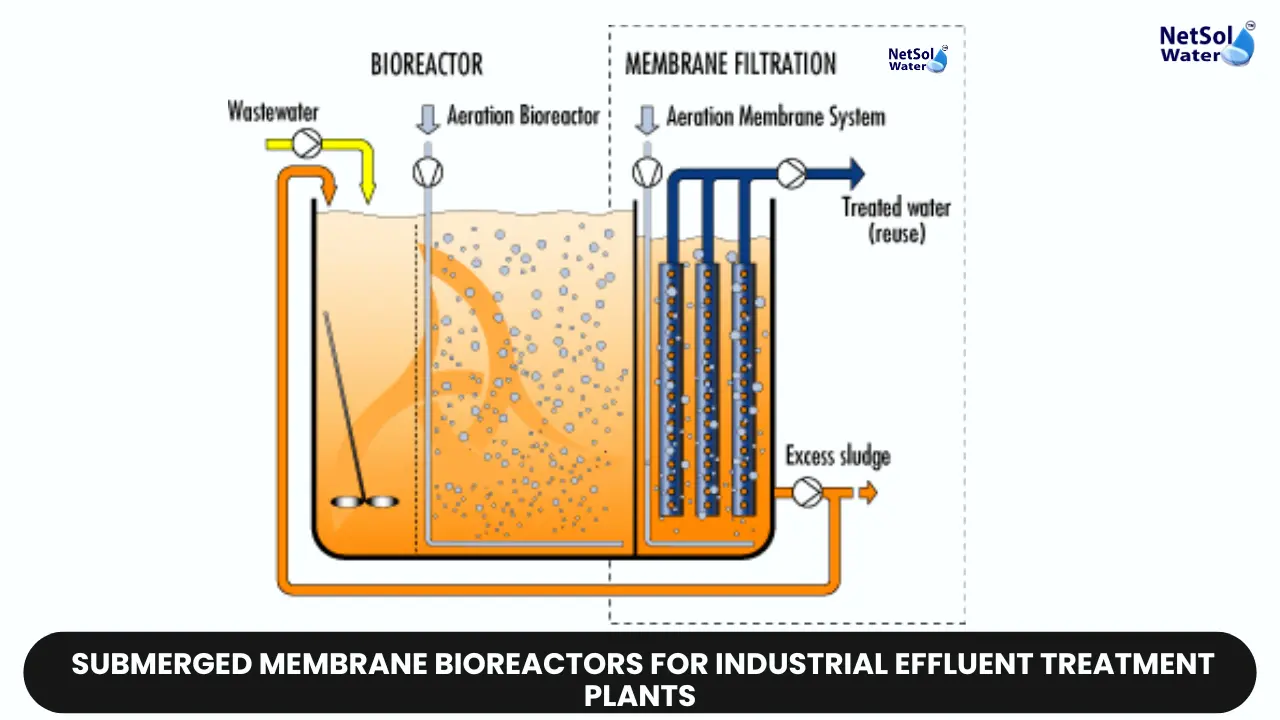

In a submerged MBR, a regular activated sludge process is mixed with membrane filtration. In this single tank, processes like cleaning the water biologically and separating various solids from it happen. The membranes are kept immersed in the water, letting the clean water pass through while keeping back the biomass and solids.

Understanding the Membrane Filtration Process

The membrane filtration process is crucial in submerged MBRs. Membranes act as physical barriers, permitting water and dissolved solids to pass through while retaining particles, colloids, and microorganisms. This process typically involves:

1. Immersion: Membranes are submerged in the mixed liquor containing activated sludge and wastewater.

2. Permeation: Low-pressure vacuum draws treated effluent through membrane pores while retaining solids and biomass.

3. Aeration: Aeration maintains dissolved oxygen levels for biological treatment and creates turbulence to reduce membrane fouling.

Biological Treatment Process

The biological treatment process in submerged MBRs is similar to conventional activated sludge processes, where microorganisms degrade organic matter and contaminants. However, the integrated membrane filtration system offers advantages:

1. Elevated mixed liquor suspended solids (MLSS) concentration: Higher MLSS enhances biomass concentration and treatment efficiency.

2. Longer sludge retention time (SRT): Membranes retain biomass, enabling longer SRTs and promoting growth of slow-growing microorganisms, improving specific contaminant removal.

3. Improved effluent quality: Membrane filtration ensures high-quality effluent, meeting stringent discharge requirements.

Advantages of Submerged Membrane Bioreactors

Submerged MBRs offer several advantages over conventional processes for industrial effluent treatment:

1. Compact footprint: Combining biological treatment and solid-liquid separation in one reactor results in a compact design, suitable for space-constrained facilities.

2. Superior effluent quality: Membrane filtration produces high-quality effluent with low turbidity, suspended solids, and microorganisms, enabling compliance with stringent regulations.

3. Efficient contaminant removal: MBRs effectively remove various contaminants, including organic matter, nutrients, pathogens, and certain toxic compounds, depending on effluent composition.

4. Operational flexibility: MBRs can handle fluctuations in influent quality and flow rates, adapting to changing industrial processes and effluent characteristics.

5. Potential for water reuse: The high-quality effluent produced by MBRs can be suitable for water reuse applications, reducing fresh water demand.

Challenges and Considerations

Though MBRs offers numerous advantages, they also have some challenges which one should be aware of:

1. Membrane fouling: Accumulation of solids, organic matter, and biofilms on membrane surfaces can reduce permeability and increase operational costs. Effective fouling control strategies, like air scouring, backwashing, and chemical cleaning, are essential.

2. Energy consumption: MBRs typically have higher energy requirements compared to conventional processes due to aeration and membrane filtration operations. Optimizing energy efficiency through proper design and operation is crucial.

3. Membrane replacement: Membranes have a limited lifespan and require periodic replacement, contributing to overall operating costs.

4. Pretreatment requirements: Depending on effluent characteristics, pretreatment steps may be necessary to remove specific contaminants or adjust pH levels before entering the MBR system.

5. Skilled operators: MBRs are complex systems that require skilled operators and proper training to ensure optimal performance and troubleshooting.

Applications and Case Studies

Submerged MBRs have been successfully employed in various industrial sectors for effluent treatment, including:

1. Food and beverage industry: Effective in removing organic matter, suspended solids, and nutrients from food processing, dairy, and beverage production effluents.

2. Chemical and pharmaceutical industries: Can treat effluents containing complex organic compounds, toxins, and high levels of suspended solids.

3. Textile and dyeing industries: Can remove dyes, organic matter, and other pollutants present in textile effluents, enabling compliance with environmental regulations.

4. Pulp and paper industry: Effective in treating effluents containing high levels of organic matter, suspended solids, and toxic compounds.

Conclusion

Submerged membrane bioreactors have proven to be an effective solution for treating industrial effluents which provides superior effluent quality, efficient contaminant removal, and operational flexibility. By combining biological treatment and membrane filtration in a single reactor, MBRs provide a compact footprint and the ability to handle varying effluent characteristics.

While MBRs present certain challenges such as membrane fouling, energy consumption, and membrane replacement costs, their advantages often outweigh these considerations, particularly in industries with strict discharge regulations or water reuse requirements.

As environmental regulations continue to tighten and the demand for sustainable water management practices increases, submerged membrane bioreactors will play an increasingly important role in industrial effluent treatment plants, contributing to the protection of water resources and the promotion of a circular economy.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com