What microbiological problems can occur in Aeration Tanks?

Let us enlist some problems that Aeration Tanks may face due to Microorganisms!

1: Pin Floc, Poor Floc Formation, and Dispersed Growth Issues

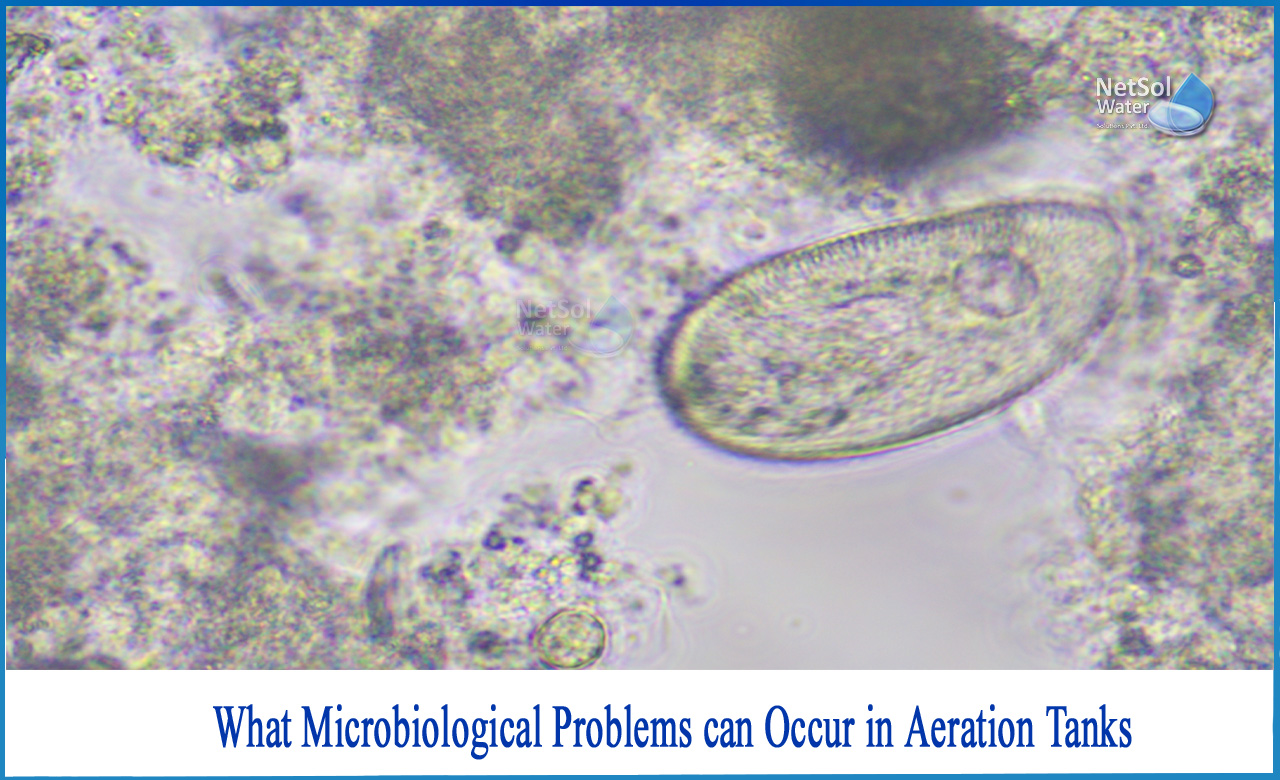

Basic floc creation is caused by a growth form of many species of natural bacteria, which is essential for aeration tank operation due to the use of gravity clarifiers. The production of an extracellular polysaccharide layer, also recognized as a glycocalyx, is a hallmark of floc-forming organisms. The carbohydrate, protein, and cellulose fibrils in this substance "cement" the bacteria to create a floc.

Floc formation occurs when growth rates are slowed and nutrition levels are low, resulting in starvation or growth halting conditions. If the development rate is too quick, floc-forming organisms may become scattered and unstable.

A:Dispersed growth is a rare occurrence in-home waste aeration tank operation, but it is common in industrial waste treatment, owing to high organic loading. There are no flocs to form, and biomass does not settle, resulting in a highly murky effluent. The correct remedy for a dispersed growth problem is to lower the system's F/M, which is normally accomplished by increasing the MLSS concentration. When the aeration tank biomass is low and high F/M conditions exist following toxicity or hydraulic washout event, dispersed growth difficulties are common.

B:Small, weak flocs can form in an aeration tank, and these can be easily sheared and exposed to hydraulic surge flotation in the final clarifier, leading in murky effluent. Pin flocs are small flocs made up entirely of floc-forming bacteria without a filament backbone that are typically 50µm in diameter. Pin floc is most common when there is a lack of nutrients in the sludge, such as a low F/M ratio and a lengthy sludge age. Pin floc is another symptom of chronic poisoning.

2: Toxicity problems

In the functioning of aeration tanks, toxic shocks might be a serious issue.

Due to the absence of dilution of harmful emissions in tiny systems, toxicity problems result to be a greater problem in small villages than in larger cities. Washing cement or lime trucks to a manhole, dumping congealed diesel fuel into the sewer system, and overloading minor systems with septage are just a few examples of toxicity incidents.

Sulphide toxicity in the aeration tank is more widespread than previously thought.It can enter the aeration tank system via outside sources, such as septic influent wastewater or septage disposal, or from within sources, such as anaerobic digester flows, aeration basins, or primary or final clarifiers with sludge build-up and anaerobic conditions. Because the poisonous agent is H2S rather than HS-, hydrogen sulphide toxicity is pH dependant.

H2S is more harmful at pH 7 or less and less toxic when pH rises over pH 7 and H2S dissociates. At pH 7, one mg/L of H2S lowers the aeration tank by 50%, while at values above pH 8, the H2S dose required to reduce the aeration tank by 50% grows to 100 mg/L.

3: Nitrification and Denitrification Problems

A:In the operation of an aeration tank, nitrification can cause issues. Every spring, when warmer temperatures cause nitrification, many plants undergo an upset situation with dispersed growth and filamentous bulking. Due to a brief period of nitrite build-up, some plants lose chlorine disinfection during the commencement of nitrification.

Nitrite, unlike ammonia and nitrate, has a high chlorine requirement. Low pH-induced by excessive nitrification and low effluent alkalinity is a major issue in some facilities. This frequently results in pin floc and significant turbidity in the effluent. If nitrification becomes a concern, some plants limit aeration or add soda ash, lime, or magnesium hydroxide as an alkalinity source. The use of lower dissolved oxygen concentrations to manage nitrification comes with the risk of low dissolved oxygen filaments causing filamentous bulking.

B:Denitrification is another issue induced by nitrification. When free oxygen is scarce, bacteria found in the aeration tank floc respire using nitrate instead of free oxygen, releasing nitrogen gas as a by-product. Small nitrogen gas bubbles occur in the aeration tank and produce sludge blanket flotation in the final clarifier since this gas is only mildly soluble in water. Holding the sludge in the settling test jar for several hours can provide an indication of the presence of denitrification.

Denitrification difficulties may be present if the sludge rises in less than 2 hours.These problems are more common in the summer, and they can be more severe if there is a filamentous sludge present, since the nitrogen gas bubbles are captured more extensively by the filamentous sludge.

If you want to know more about various problems in aeration tanks, then you can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.