What is grit?

Grit is non-putrescible, havinga higher hydraulic subsidence value than organic solids. The specific gravity of the grit ranges between 2.4 to 2.65.

The composition of grit varies depending upon the following conditions-

• Types of street surfaces encountered;

• Relative areas served;

• Climatic conditions;

• Types of inlets and catch basins;

• Amount of stormwater diverted from combined sewers at overflow points;

• Ground and groundwater characteristics;

• Industrial wastes and

• Social habits.

Grit can be disposed off to remove larger size organic matter settled along with grit particles; whereas, the suspended solids settled in primary sedimentation tanks, being organic matter, requires further treatment before disposal.The places where water or wastewater treatment technologies could be damaged by the presence of sand, grit chambers allow for the removal of heavy inorganic fractions by settling.

How to calculate Velocity Control in Grit chambers?

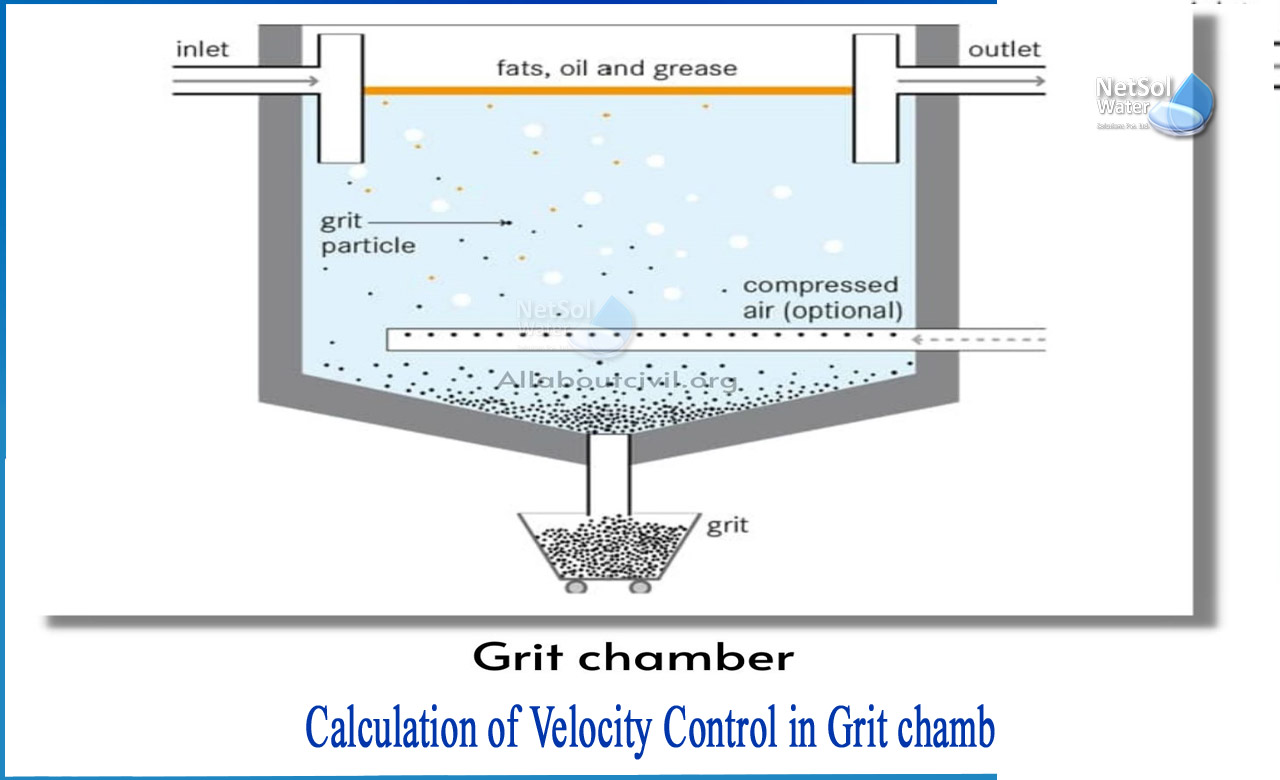

Grit chamber is a long rectangular or circular tank in the primary sewage treatment plant that is designed to remove grit or other heavy solids that have specific gravity much greater than the organic solids in wastewater. Grit chamber is used in primary treatment of wastewater for the purpose of removing suspended inorganic particles such as sandy and gritty matter from the wastewater.

The grit chamber reduces the velocity of the flow of sewage or wastewater to eliminate the grit materials such as sand, ash and clinkers, eggshells, bone chips and many inert materials inorganic in nature. Grit chambers are provided to protect moving parts of treatment plants from abrasion; avoid deposition in pipesand conduits; and to reduce frequency of digester cleaning. Removal of suspended inorganic solids in grit chamber is done by washing as it does not require any further treatment.

Advantages of Grit Chamber

i) To protect moving mechanical equipment’s from abnormal wear.

ii) To reduce maintenance cost of digester cleaning caused by excessive accumulation of grit.

Iii) To prevent heavy deposits in pipelines and channels.

Types of grit chamber

Generally there are three types of grit chambers:

a) Horizontal-flow grit chamber

b) Aerated Grit chamber

c) Vortex type grit chambers.

All of these designs allow grit particles to settle down, while lighter organic particles remain in suspension.

Depending upon the other factors such as the type of grit to be handled, head loss requirements and economic considerations, with respect to both capital and operating costs, grit chambers are divided into-

1: Mechanically Cleaned

2: Manually Cleaned.

Control of velocity through the grit chamber

There is variation in sewage flow received at a treatment plant. So,it is important that velocity of the wastewater in the grit chamber should be maintained nearly constant. Due to lowering of velocity, not only inorganic solids get deposited but deposition of organic solids will also occur in grit chamber. With flow higher than average,scouring of already deposited grit particles will occur, leading to performance failure. For proper functioning, the velocity should not be allowed to change in spite of change in flow in the grit chamber. This can be done by introducing proportional weir. The shape of the opening of a proportional weir is made such that the discharge becomes directly proportional to liquid depth in grit chambers. The velocity of water remains constant for all flow conditions.

The discharge through proportional weir is given by the equation:

Q = Cb√2ag( H-a/3)

Where, Q = Discharge, m3/sec

C = constant (For symmetrical sharp edged weir,the value is 0.61)

a = 25 to 35 mm

b = base width of weir

H = Height of water above the level of crest

The equation of the curve which forms edge of the weir is given by the following formula:

x= b/2 [1-2/π ?tan?^(-1 )√(y/a-1) ]

The sharp edges at the bottom are curtailed on both the sides, as these small openings will not contribute for flow due to deposition of solids. To compensate the loss of area, the edge of the weir is lowered by a distance equal to(a/3) than the theoretical level.

Conclusion

Netsol Water is one of the leading water and wastewater treatment company in India with services in the field of WTP manufacturing, WWTP manufacturing, STP manufacturing, ETP manufacturing, among other services. The company designs and manufactures machines and is dedicated to practical solutions that spur business growth and simultaneously preserves world’s most precious resource- WATER!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.