What actually is anaerobic digestion?

Anaerobic Digestion (AD) is a method used in the municipal and industrial sectors to digest biosolids and trash. It emits methane gas, which is commonly used as a fuel in Combined Heat and Power (CHP) plants to create electricity. Municipal systems, which have more ammonia and phosphate content than industrial biosolids, can develop an undesired hard scale called struvite, which has the potential to cause process difficulties. Struvite scale is most likely to form as a result of the digesting process's digestate, which is a nutrient-rich biosolid sludge leftover.

What is Struvite Potentials and Drawbacks in Anaerobic Digestion?

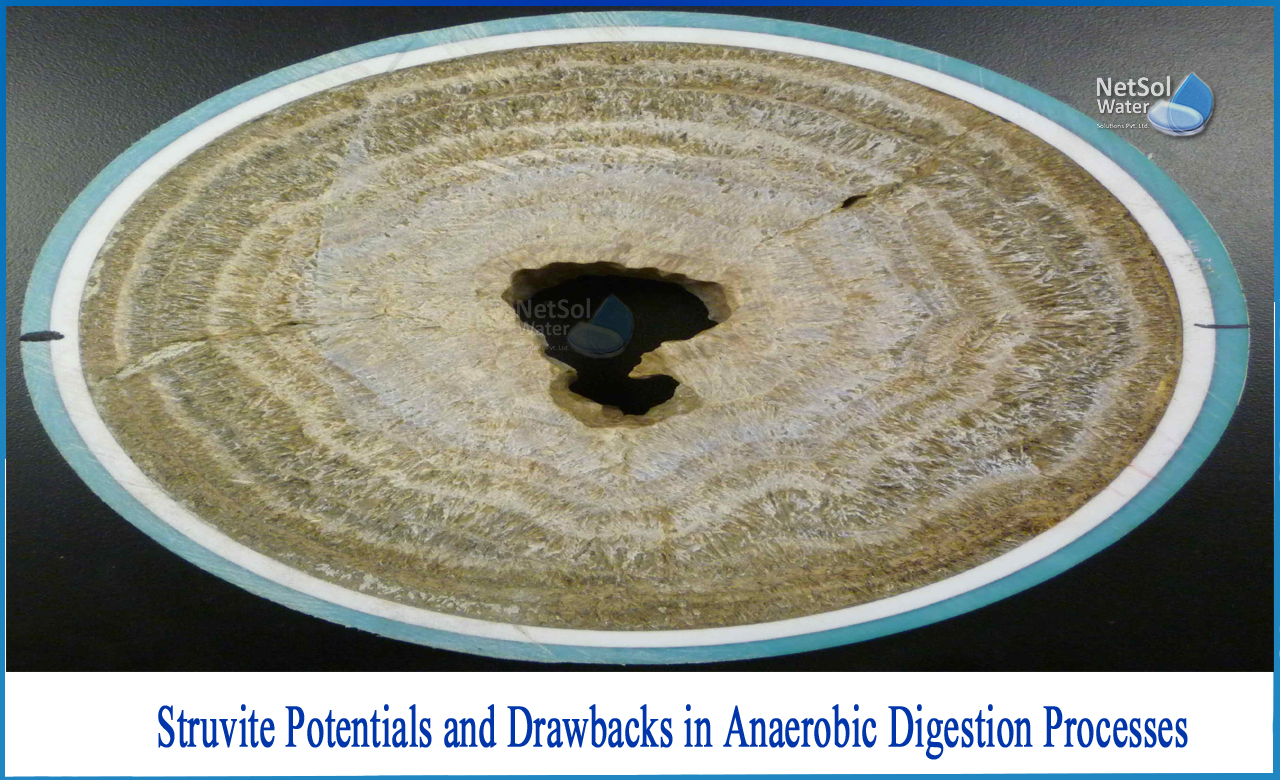

When magnesium ammonium phosphate reacts to create a crystalline solid, struvite is generated. This mixture is very insoluble, and under the right circumstances, crystals form, a process known as super saturation. These crystals are often visible. These are difficult to remove when this scale accumulates on pipes, pumps, heat exchangers, and centrifuges and thus can cause process downtime as well as the accompanying recurring OPEX maintenance expenses.

Struvite often forms in the dewatering stage of the process, where digestate is dewatered. Three critical variables are necessary for the formation of struvite

The presence of magnesium phosphate and ammonia in a 1:1:1 molar ratio, a pH more than 7.5, and a temperature range of 10-40oC. Using the centrate of a centrifuge as an example, it is clear why and how struvite has the ability to cause problems in the process.

The centrifuge's turbulence and subsequent pumping can cause carbon dioxide to be removed from the effluent, resulting in an increase in pH. It is easy to understand why struvite is easily precipitated when mixing, pumping, and processing occurs as part of the dewatering process when typical AD processes operate around 30-40oC with regulated pH’s of 6.5 – 7.5.

Struvite's Potential

Struvite can be an unwelcome, expensive, and difficult-to-control byproduct of an AD process, but it can also be handled, controlled, and harnessed to make a commercially viable product. An additional benefit is the removal of phosphate from the entire treatment process, which reduces loadings back into the plant while also helping to satisfying phosphorous consent at the site of release.

Chemicals for Struvite Control

Struvite can be reduced by altering the magnesium ammonium phosphate ratio. This can be tackled chemically by removing phosphate from the mix and so lowering the proclivity for struvite production. Typically, this is accomplished by the administration of metal salts such as ferric and aluminium. This technique has a low initial CAPEX need but high recurring OPEX expenditures. These compounds create a stable combination with the phosphate, lowering the concentration of phosphate in solution and minimizing the possibility of super saturation.

Chemicals like ferric chloride are extremely corrosive, increasing the chloride content of the centrate/filtrate and generating a high amount of inorganic sludge. Phosphate recovery is very difficult with this way of control since it is permanently coupled with the metal-based addition. A suitable disposal method for the sludge is also necessary, which adds to the expense.

Harvesting Struvite Control

Harvesting or regulating struvite precipitation is another approach for reducing the impact of undesirable struvite deposition on assets while also creating a commercially viable phosphate rich fertiliser. Rather than inhibiting struvite precipitation, this can be accomplished by actively stimulating struvite crystal formation in a regulated manner.This is essentially the harvesting of struvite crystals in a reaction vessel by ensuring the necessary formation requirements for supersaturation are satisfied. In this case, magnesium is often scarce, thus it is supplemented to reach the 1:1:1 ratio. Struvite is precipitated in a regulated way using this method before it may produce scaling or asset deposition concerns. Furthermore, the nutrient-rich solid has the potential to generate money by producing a value-added product that may be used in the fertiliser production process.

What can Netsol Water offer?

Netsol Water provide complete project support, from professional advice on proposals to ongoing maintenance performed by our specialized staff of experts. We also provide process assurances, which provide you piece of mind that the needed performance will be met on a constant basis.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.