What is Sludge Wasting?

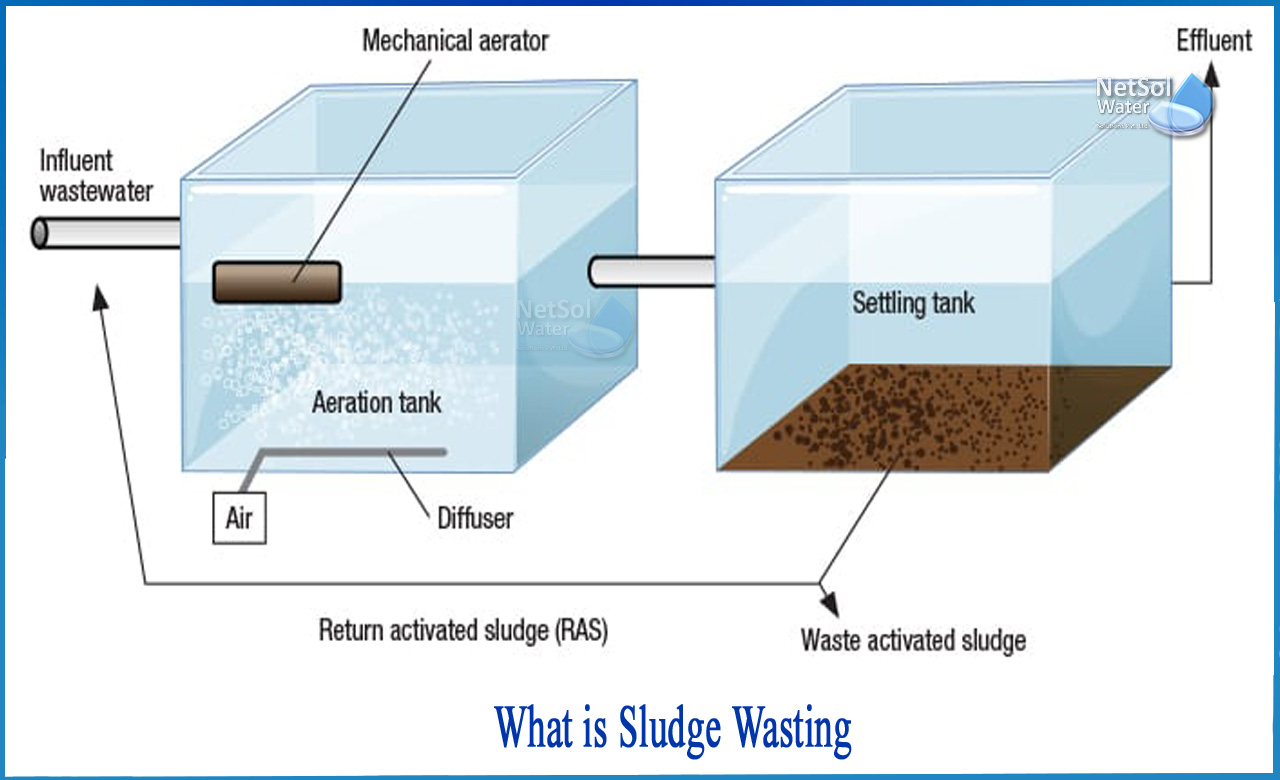

One of the most extensively used technologies for biological wastewater treatment is the conventional activated sludge process, for which the operator is familiar with the essential operational parameters and how to control them.

Operators use a variety of process parameters such as organic loading rates, dissolved oxygen concentration, Sludge Volume Index (SVI), Food to Mass Ratio (F/M), Oxygen Uptake Rate (OUR), MLSS to MLVSS ratio, and RAS flow to control and maintain proper operating conditions. But there is one parameter that sticks out above the rest: sludge wasting. It's just as important to waste sludge in the right proportions on a daily basis and maintain the MLSS refreshed at all times as it is to provide the right amount of air to the aeration basins.

Quantity of wasting sludge

Determining how much sludge is in the plant is a key parameter when it comes to sludge waste. A settlometer is a device that performs a helpful process control test to estimate the amount of sludge in a plant. Once the amount of sludge has been calculated, a choice can be made about how much sludge should be disposed of and how that sludge should be disposed of.Normally, a major part of the sludge is never wasted in wastewater treatment; nevertheless, in packaged treatment plants, operators may squander up to 50% of the sludge.

Consequences of not wasting sludge

The activated sludge process is affected by sludge, therefore it is necessary to maintain the MLSS replenished by waste on a regular and ongoing basis.

The following are some of the consequences of not wasting sludge:

1: The inorganic part of the MLSS accumulates, lowering the MLVSS/MLSS ratio. If a higher ratio suggests higher biological activity, then the actual activity of biomass is reduced for each gram of MLSS kept in the aeration tank.

2: It is a common occurrence in the activated sludge process that MLSS acts as a binding agent or adsorptive media for many of the toxic pollutants present in the incoming wastewater, and if not discarded on a continuous basis, its concentration will continue to rise in the aeration tank within the inorganic MLSS fraction, causing severe toxicity events on the biological activity and lowering its performance.

3: Increasing the inorganic fraction also enhances gravity and weight of the MLSS, so if the mechanical equipment delivering air isn’t up to par, the sludge will begin to settle at the bottom of the tank, causing severe deposition.Unfortunately for many industries, this is the sole sludge wasting mechanism that allows the sludge to settle in the bottom of the tank rather from being formally discarded, resulting in limitless sludge age.

4: A high sludge age results in an unusually low FM ratio in the aeration tank, which has an impact on the general population dynamics of the biomass fraction and, in practise, helps predators thrive by allowing them to feed on live biomass rather than incoming organic carbon. This limits the actual capability for organic elimination even further. In fact, the biomass engages in cannibalism, which reduces the amount of incoming organic carbon source-eating bacteria and, over time, reduces the plant’s ability to lower COD.

5: A very low FM Ratio also causes deflocculation issues for the MLSS, resulting in the formation of pin flocs or disperse growth, reducing the MLSS’s settling properties and causing excessive TSS carryover in the clarifier outlet, which raises the effluent COD values even more, as 1 gm TSS containing biomass has a COD value ranging from 0.85 to 1.42 g COD/TSS depending on its organic.

6: Another effect of exceptionally high sludge age is the reactor’s ability to withstand hazardous shock loads. A minor increase in the harmful pollutant in the inflow will cause the process to be disrupted, resulting in additional performance degradation.

Conclusion

Finally, filling the aeration tank with MLSS is a bad operational practice that must be corrected. We work with a variety of companies and operators to help them increase the quality of biomass in their aeration tanks rather than the quantity.

If you want to know more about the wasting of sludge, then you can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.