What is the best place to set up a commercial RO plant?

Your RO system can be put in a basement or under a sink in a residential facility or a terrace in a commercial facility.

Install the device in a location where it will not be exposed to cold weather. If a connection can be made without using more than 12" of tubing, connecting to a remote site might be considered; otherwise, a delivery pump may be required. Further runs can be performed, and if necessary, a pump can be added afterwards.

The location of RO system is chosen wisely, we should consider the place with minimum possible distance of electric connection, the dry place with relatively less humid conditions and reachable location which is approachable to all.

The following are some guidelines regarding component placement-

1: Faucet

Faucet should be installed on or near the sink where drinking/cooking water is often used. A score of two "If there isn't an existing hole, a level surface is necessary to attach the faucet. The mounting surface should be no more than 1-1/4 inch thick. Alternatively, a faucet extender (not included) would be required.

2: Bladder Storage Tank

It might be put at a handy location, such as within 10 feet of the faucet. Because full tanks may weigh up to thirty pounds, be sure any place you choose is sturdy. The bladder tank can be positioned vertically.

3: RO unit

The RO unit can be installed on either side of the sink, under a cabinet, in the basement or a terrace. The unit may be mounted on the left or right side of the cabinet making it simpler to reach for future maintenance.

4: Angle stop valve

A feed water connection to the RO unit is provided via an Angle Stop Valve. This assembly should be placed as near to the RO unit as practicable. It connects the top of your cold water shut-off valve to the bottom of the riser tube that runs between it and the faucet.

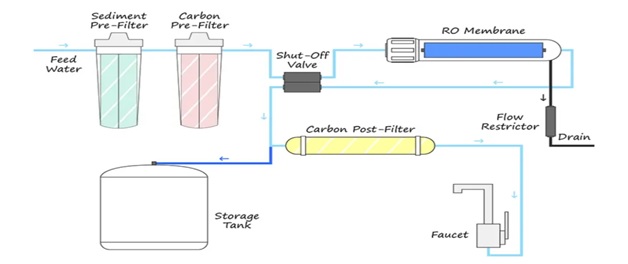

RO water plant connection diagram

Here's an easy-to-understand diagram of how the RO system works. The phases are identified in the RO water plant flow diagram, while the arrows indicate water flow, i.e. the plumbing connection.

Despite their differences in quality, most RO plants have the same appearance. The components are also standard and function in the same way. These are the components of a conventional RO plant and the associated plumbing line from input to output:

1. Intake Valve: The inlet valve is the RO system's water supply. The valve is usually installed on the cold-water line.

2. Pre-Filter: To protect the membrane from salt, silt, and chlorine, most ROs include a pre-filter. Typically, a sediment or carbon filter is used.

3.RO Membrane: The RO membrane is the most important component for removing substantial health risks.

4. Post-Filter: Purified water passes through a post-filter before reaching the faucet. A polish filter is another name for it. The by-product tastes sweeter and fresher as a result of this filter, which removes odour and poor taste.

5. Storage Tank: The filtered water is kept in this pressure tank until the customer turns on the faucet.

6. Backward Flow Limiting Valve: A restricting valve is used to keep treated water from flowing back into the storage tank. Reverse flow has the potential to harm the membrane by rupturing it.

7. Drain Line: The drain line is primarily connected to the RO membrane's output end. It releases contaminated and impurity-laden effluent. The reject water is usually put to a good use such as watering plants or garden etc.

8. Faucet: A faucet is a treated water flow-controlled tap that is commonly put on the reachable areas in sinks. In commercial spaces, these faucets are fixed at different places.

The best commercial RO plant manufacturers in India!

Netsol Water collaborates with a wide range of international organizations to tackle complicated problems of RO by strategically integrating modern treatment technology with practical solutions. Also, we can provide a good framework of plumbing connections of RO plants.

Our plants are made with great care and attention to detail, which is why they function so well. Our systems can provide clean, pure, filtered water if your company uses it. These plants are both cost-effective and efficient, capable of generating thousands of litres of pure, filtered water.