What is the WWT and working of ETP in Automobile industry?

The automobile industry is the fastest growing industry in the world, and with this growth, production has grown as well. With some key changes in the production process, the need for water treatment has become critical, not only to keep the carbon footprint as low as possible, but also to continue operations with less environmental damage than is currently the case.

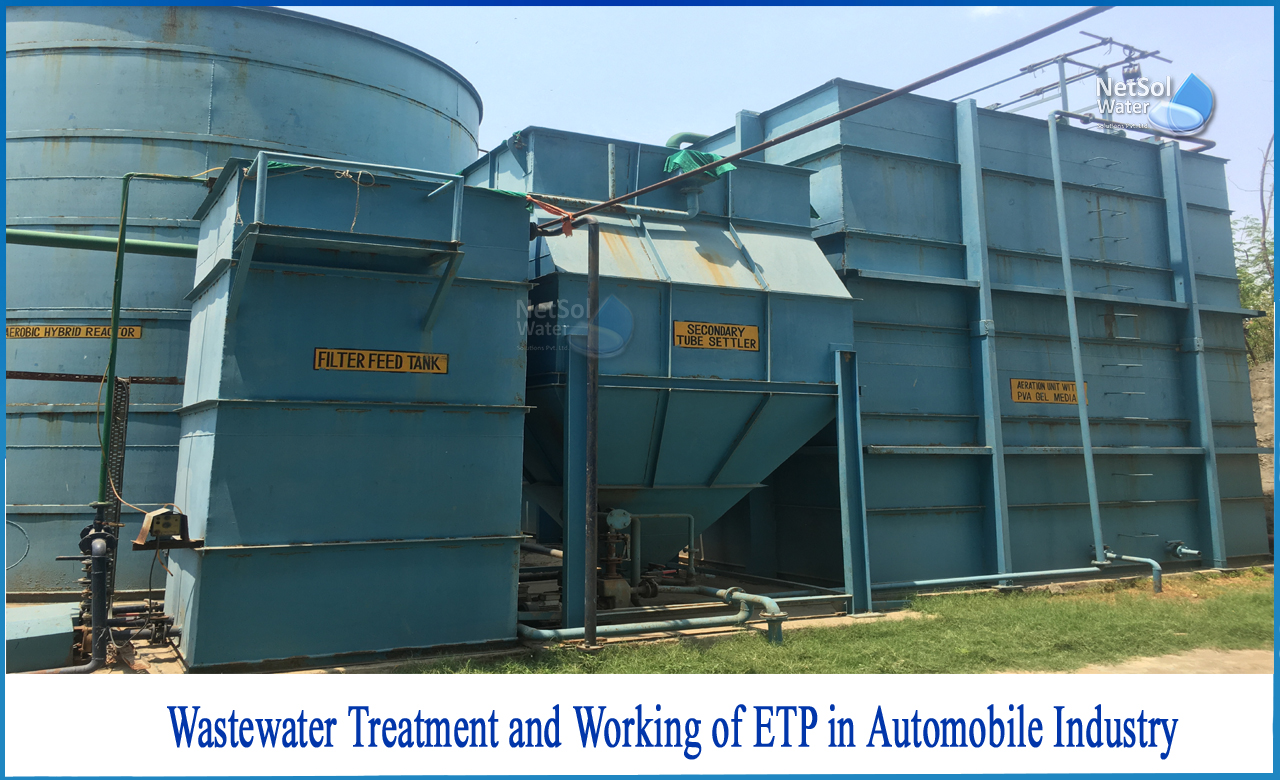

In order for this to work, water treatment plants, specifically Effluent Treatment Plants, must be installed. ETP is critical in reducing the pollutants and contaminants in the water to an acceptable level before releasing it into nature.

ETP for automobile industries involves several major processes:

They are as follows:

Physical - Sedimentation (Clarification), screening, aeration, filtering, flotation and skimming, degasification, and equalization.

Chemical - Chlorination, ozonation, neutralization, coagulation, adsorption, and ion exchange are all chemical processes.

Biological –

A. Aerobic – Methods of treating activated sludge, such as trickling filtration, oxidation, ponds, lagoons, and aerobic digestion.

B. Anaerobic – This category includes anaerobic digestion, septic tanks, and lagoons.

The treatment procedure can be broken down as follows:

I. Primary treatment – Removal of suspended solids, oil, grit, and other contaminants.

II. Secondary treatment – Use of microorganisms in aerobic or anaerobic conditions to reduce BOD and remove colour, oil, and phenol.

III. Tertiary treatment – It entails the use of electrodialysis, ion exchange, and reverse osmosis to remove and purify the wastewater.

Automobile industry effluents are treated with physical and chemical treatments such as coagulation, flocculation, ozonation, and biological treatment to remove nitrogen, phosphorous, organics, and metal traces.

The disadvantages of physicochemical processes include the formation of sludge, disposal of sludge, and the required space.

The disadvantages of biological processes include the presence of toxic heavy metals, which inhibit the growth of microorganisms, the fact that most of the dyes used are not biodegradable in nature, and the longer treatment time.

What are the contaminants found in automobile industry?

Automobile industry effluent contains chlorides, paint impurities to paint two and three-wheeler parts, and mineral oil from coolant impurities used in machine shops. When coolant is discharged into water, it raises the COD of the effluent.

The automotive industry has two treatment plants, one ETP and the other CTP. In comparison to other industries, the parameters of automobile effluent are low, with a slightly lower organic and inorganic load. Recently, the “Pollution Control Board”has become extremely strict regarding the ETP outlet water parameters. The health of the environment is critical to the health of humans.

Most industries used to send their effluent without treatment, but this is no longer possible. Every industry takes great care with water.

ETP is essentially required:

1: To purify industrial effluent and recycle it for future use.

2: In order to reduce the use of fresh/potable water in industry.

3: To reduce spending on water procurement.

4: To meet the Government's standards for the emission or discharge of environmental pollutants from various industries and avoid hefty penalties.

5: To protect the Environment from pollution and to contribute to long-term development.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.