Does hydrogen sulfide or H2S cause corrosion?

The presence of H2S in sanitary sewer systems cause a slew of issues, including corrosion, which poses its own set of concerns. When anaerobic slime from submerged pipe walls rises into the sewer pipe's airway and combines with bacteria and moisture on the pipe walls, hydrogen sulphide fumes are released. Within wastewater conditions, biogenic sulphide corrosion, a bacterially driven process of hydrogen sulphide gas conversion to sulphuric acid, destroys concrete and steel. As a result, designers' goal is to remove the corrosion and health risks connected with H2S.

There's no denying that H2S is a dangerous substance!

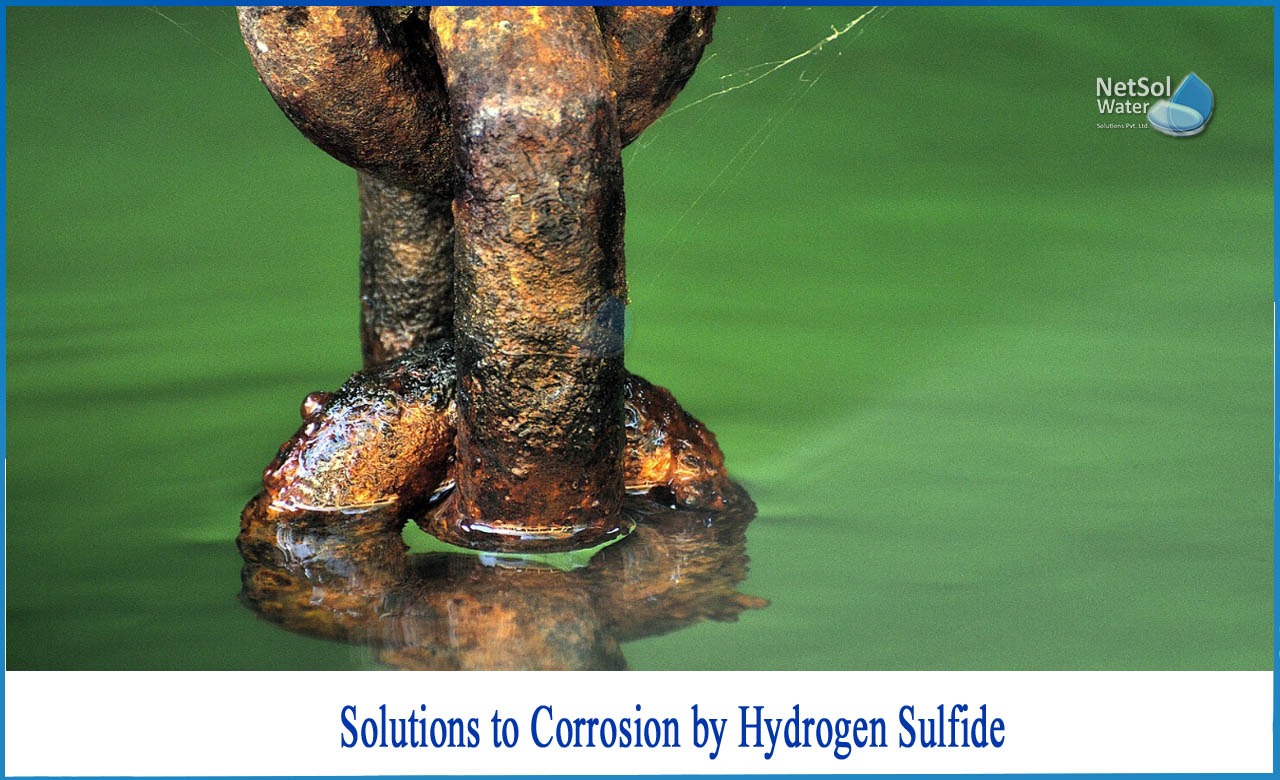

Not only does the colourless gas have a rotten egg odour, but it's also combustible and potentially explosive in high amounts. Corrosion of metals and concrete is also a result. Biogenic sulphide corrosion increases sewer assets by billions each year. That expense will rise as ageing infrastructure continues to fail. Steel, copper, brass, and iron in well casing/plumbing/bathroom fixtures can be severely damaged if there is more than 0.5 ppm of hydrogen sulphide in the water.

Bad Effects of H2S

H2S is produced in sewers and is the result of a multi-step process involving biological, chemical, and physical routes.

Sulphate (naturally and harmlessly occurring in nearly all drinking water supplies) is converted to ionic sulphide by natural microorganisms living below the waterline in a sewer, which then transforms chemically into dissolved H2S. The dissolved hydrogen sulphide is only liberated from the water as H2S gas when splashing and turbulence occurs, resulting in a foul odour.

H2S (hydrogen sulphide) exists in two phases: liquid and vapour.

1: Unless it's in a combustible setting, the liquid stage is usually unimportant.

2: The odour of "rotten eggs" is present in the second phase, the vapour phase.

Concrete and metal are both highly corrosive. Hydrogen sulphide is formed when wastewater in a collection system stops moving, which is known as "septic" conditions. SRBs (sulphate-reducing bacteria) go to work when the wastewater becomes anaerobic. Thiobacillus bacteria living above the water line converts hydrogen gas to sulphuric acid. The acid then falls into the wastewater, where it is neutralised and converted back to sulphate, repeating the process.

Solutionsto H2S corrosion

1: Cathodic Protection - A strategy for reducing corrosion by making the material work as a cathode while having a second, more easily oxidised material in direct contact, which acts as the anode and corrosion site. This means that the second material, such as zinc, will experience the majority of the corrosion rather than the subject material, such as the iron pipeline, which will be preserved.

2: Galvanization - Two distinct metals or metal alloys are placed in the same electrolyte solution in this method. The metal or metal alloy with lower corrosion potential coats the material to be protected and acts as an anode by polarising towards a higher potential (positive shift), whereas the metal or metal alloy with higher corrosion potential acts as a cathode by polarising towards a lower potential (negative shift). This means that the material with the lowest corrosion potential will corrode considerably more quickly than the material with the highest corrosion potential.

3: Chemical Inhibitor - One of the most efficient ways to prevent hydrogen sulphide is to use a chemical inhibitor in the fluid. An iron sulphide layer wraps the substance where the chemical inhibitor is adsorbed stably in a high concentration of hydrogen sulphide

Conclusion

Under certain experimental conditions, hydrogen sulphide (H2S) can either promote or impede iron corrosion.Under certain special conditions, such as when H2S concentration is below 0.04 mmol dm-3, pH value of electrolyte solution is within 3–5, and the immersion time of the electrode is over 2 h, H2S can also have a strong inhibition effect on iron corrosion

What can Netsol Water offer?

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, and ETP manufacture, among other services. Netsol Water is committed to providing our valued customers with hands-on service, expert counselling, and training. Every environmental problem and its management have a solution and we try to provide these solutions at maximum.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.