How do you control odour in wastewater treatment?

In the modern world of wastewater treatment, odour control has evolved from most collection and treatment facility design considerations to retrofitting. As development spills over to our facilities and our new neighbours become less tolerant of unpleasant odours, wastewater experts need to make odours an important concern in the design and operation of collection and treatment facilities. As the focus on odour control grows, so does the number of odour control technologies in the market.

There are virtually an unlimited number of inherent problems and challenges in this area, and it is not possible to identify one technology as the most appropriate for all situations. We hope that this blog will serve as a guide for choosing the most appropriate technology based on the unique characteristics of your particular application.

The place or process where wastewater is collected, transferred or treated can produce an unpleasant odour!

However, most odour problems occur in collection systems, primary processing plants, and solids processing plants. In most cases, the odour associated with the collection system and primary treatment facility occurs as a result of an anaerobic or "septic" condition. This condition occurs when the transfer of oxygen to wastewater is restricted. In anaerobic conditions, there is no dissolved oxygen available for the microorganisms present in the wastewater to breathe.

What causes bad odour?

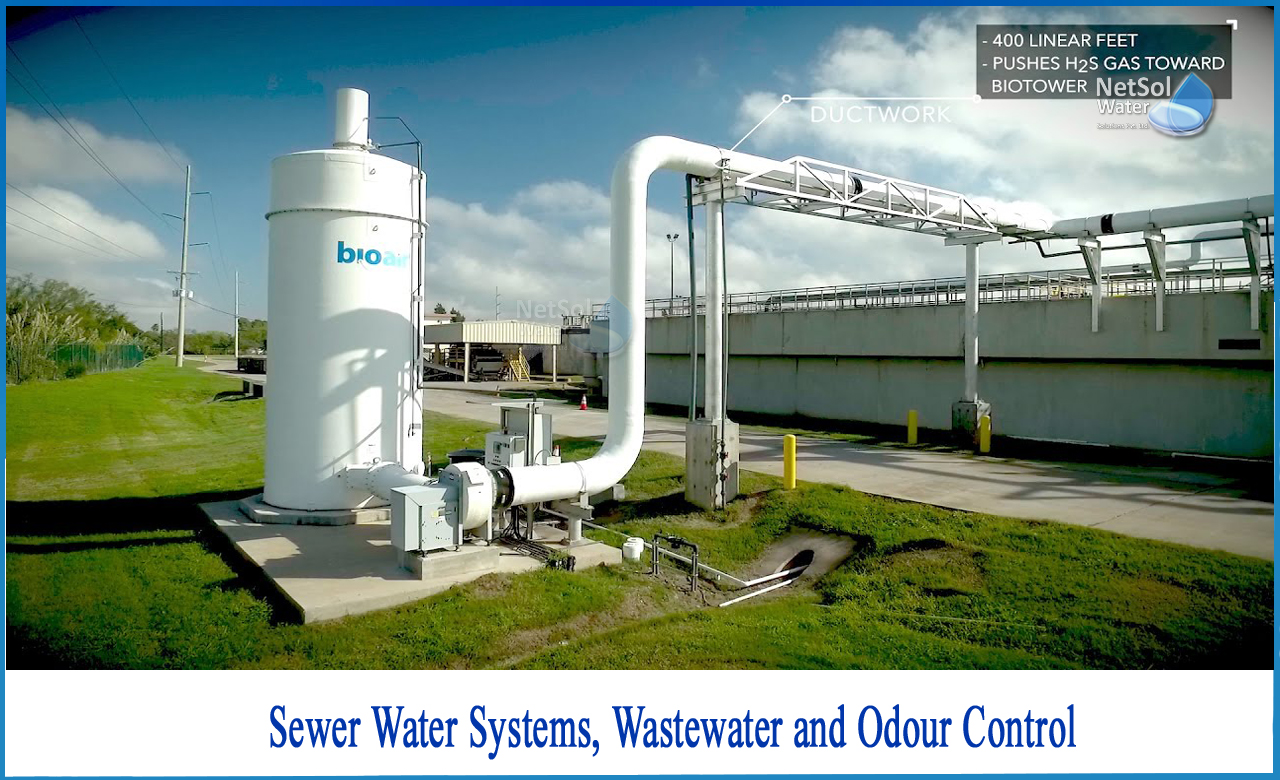

This allows a microorganism known as a "sulphate-reducing bacterium" to grow. These bacteria use naturally occurring sulphate ions (SO4) in most bodies of water as a source of oxygen for respiration. A by-product of this activity is hydrogen sulphide (H2S). This by-product has low solubility in wastewater and has a strong unpleasant rotting odour. In addition to its odour, H2S can also cause serious corrosion problems. Due to its low solubility in wastewater, it is released into the atmosphere in areas such as moist wells, superstructures, sand traps and primary purification equipment. Other "organic" odorous compounds, such as mercaptans and amines, are usually present in these areas, but H2S is the most common compound.

The solids processing facility is another area with serious odour problems!

During the bio solid dehydration and processing, bio solids are typically exposed to extreme turbulence, pH regulation, and/or heat treatment. Depending on the type and treatment of the bio solidstream used, the odorous compounds released will consist of any combination of compounds of various concentrations, such as ammonia, amines, hydrogen sulphide, organic sulphides, and mercaptans. In addition, anaerobic digestion of sludge creates anaerobic conditions for the growth of sulphate-reducing bacteria, leading to the formation of hydrogen sulphide. Hydrogen sulphide is discharged in the digestive tank. Biogas is formed from the digestion of sludge.

There are many different technologies that can be used to control odours from wastewater collection and treatment systems.

These technologies can be divided into two main groups-

1: Gas phase technology used to control odorous compounds in air or gas.

2: Liquid phase technology used to self-control compounds that cause odoursin liquid wastewater.

Gas phase technology is typically used in point source applications such as sewage treatment plants and pumping stations, or for treating biogas. Liquid phase technology is typically used in collection systems where odour and corrosion control is a concern and/or multisite odour control is the goal.

The design of the gas phase is determined by the aeration rate of the headspace being treated and the heavy load of pollutants that volatilize from the wastewater into the gas phase. The liquid phase design is determined by the flow rate of wastewater and/or the total mass load of contaminants in the liquid phase. The rates of aeration and degassing in response to liquid flow and mass loading vary widely depending on the individual application.

VapourPhase Technologies

For air treatment, the ventilation system is designed to maintain negative pressure in the area at all times. This prevents odorous air from "leaving" from vents, manholes, access hatches, or other areas. Exhaust from the ventilation system is the only way to dissipate odorous air and must be treated. Gas phase systems are very effective in preventing temporary emissions from aerated sources and preventing odour problems associated with those sources.

When ventilating large amounts of air, the gas phase system is also effective in providing adequate ventilation to the occupants and reducing pollutant levels to levels that pose no safety or risk of corrosion.

Biogas treatment systems are primarily involved in the removal of hydrogen sulphide and prevent the formation of sulphur dioxide (SO2), the combustion product of gases containing hydrogen sulphide. Most anaerobic treatment plants burn methane-rich biogas from anaerobic digestion (either as flue gas in flares or in engines, turbines, or boilers to produce electricity or steam).

The other methods of odour control are:

1: Wet Air Scrubbing

2: Liquid Redox Technology

3: Bio filtration

4: Carbon adsorption

5: Liquid-phase technologies

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.