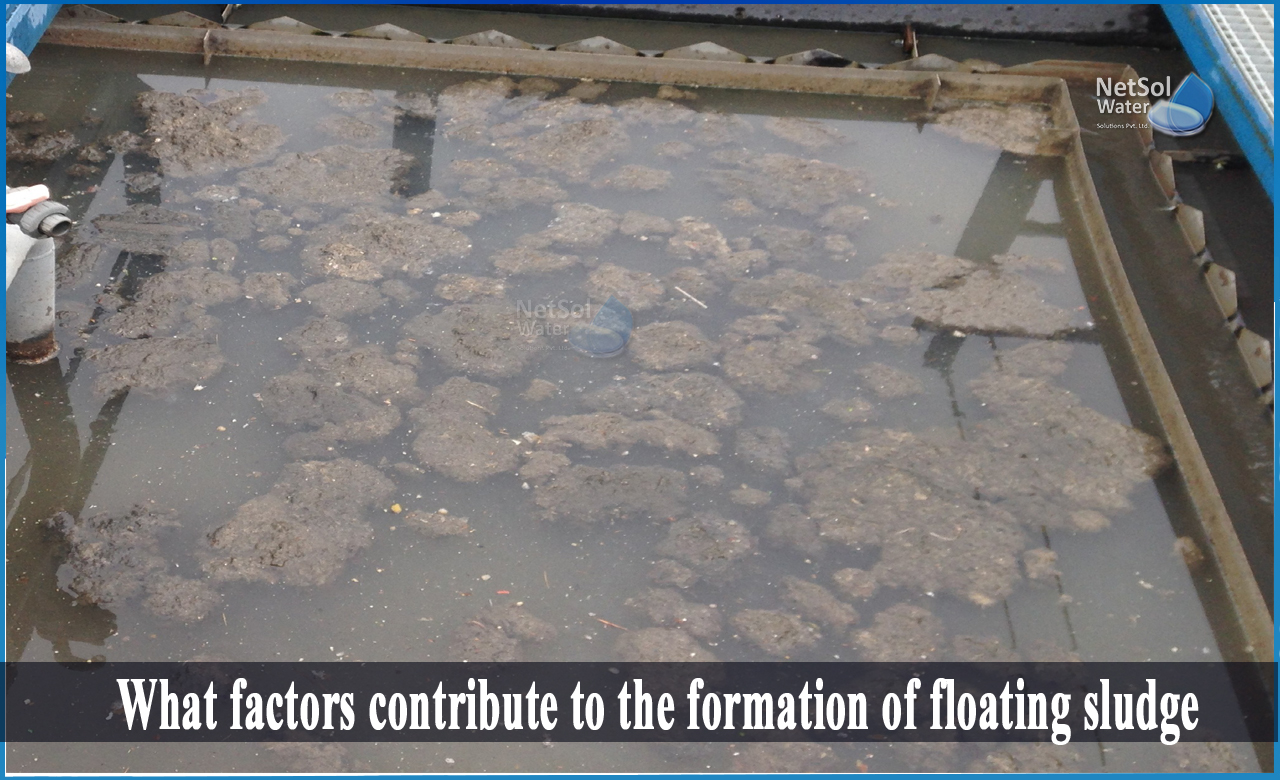

What factors contribute to the formation of floating sludge?

Solids can float and carry over the weir into the effluent when secondary clarifiers are functioning smoothly.

Factors contribute to the formation of floating sludge

The most common causes of floating sludge are;

1: Denitrification, which occurs when minute nitrogen gas bubbles float over the sludge in the clarifier, resulting in floating sludge chunks with trapped microscopic bubbles.

2: FOG which also floats on water. Excess grease or oil can create floating biomass when enclosed in floc. This appears as a thick scum blanket that can completely cover the clarifier.

3: Billowing sludge or viscous bulking can sometimes result in floating sludge (more often it is just billowing over the weir versus floating). Nutrient shortages (usually low phosphate) in industrial waterways are frequently to blame.

4: Excess EPS- While EPS is required for floc production at normal concentrations, excess EPS can result in non-filamentous bulking. The sludge is less thick and can trap air and nitrogen bubbles, causing the sludge to float.

5: Filament foams of Nocardia and M. parvicella- On the aeration basin, both Nocardia and M. parvicella form thick foam. This foam can persist in subsequent clarifiers, resulting in excessive effluent TSS.

Floating solids on a secondary clarifier are frequently a result of a change in influent composition or biological activities that have deviated from optimal. While some floating solids aren't a huge deal, excessive solids concentrations can raise effluent TSS, resulting in biological solids waste that goes unnoticed.

What are the possible solutions for these floating solids?

A-Denitrification difficulties can often be handled by boosting the recycle pump, which reduces the sludge blanket depth/sludge retention time in the clarifier. The issue is frequently linked to an increase in influent ammonia/nitrogen, which is transformed into NO2 or NO3 by beneficial nitrifiers via the autotrophic nitrification process. This process occurs in the clarifier because there is no anaerobic/anoxic stage in the treatment system to remove NO2 or NO3.

Evaluation of influent TKN/ammonia, anoxic denitrification zone residence time, availability of "food" or easily available BOD in the anoxic zone for denitrification, and an overall system assessment on sludge age, residence times, and influent make-up are all long-term solutions.

B-FOG-created floating sludge needs a time-consuming control procedure. Scum/floating sludge must first be removed or allowed to pass over the weir to polishing/tertiary treatment. Operators upstream must determine the source of the FOG growth. This can be a one-time slug or a gradual increase in grease loading. It is preferable to avoid allowing oils and grease into the biological treatment system.

C-Viscous Bulking - The solution here is to examine variations in influent makeup as well as changes in the biological treatment unit's ambient parameters. Operators must begin wasting the thickening, viscous sludge while they investigate the specific source of the bulking. If nutrient residuals are low (1.0 mg/L ammonia nitrogen or 0.5 mg/L orthophosphate), provide nutrients to raise residuals above the goals. If there is a lot of wastage, we recommend introducing cultures to help the biomass transition.

Once you've determined what's causing the floating solids, you may choose from a variety of control choices. The key is to pinpoint the source of the floating solids, implement a fast control approach to preserve effluent compliance, and then take longer-term measures to limit the possibility of future floating sludge incidents.

Netsol Water provides a complete variety of standard and fully configurable wastewater treatment systems, as well as their comprehensive maintenance. Choosing a trained, accredited, and experienced wastewater system specialist will considerably boost your chances of long-term satisfaction with your overall system.

We are also delighted to assist you in the diagnosis and treatment of wastewater. We have qualified technicians on hand to provide a wide range of professional repair and modification services. Each system is custom-built as per the needs of our client’s. To begin the conversation, please contact us at +919650608473 or send an email to enquiry@netsolwater.com for further information or product purchase related query.