Overview

Grease traps, also known as grease interceptors, converters, catchers, grease recovery/management devices, or FOG traps, have been around for over a century. They are used in a variety of settings, including restaurants, cafes, takeaways, pubs, bars, and inns, hotels, schools and colleges, and bakeries.

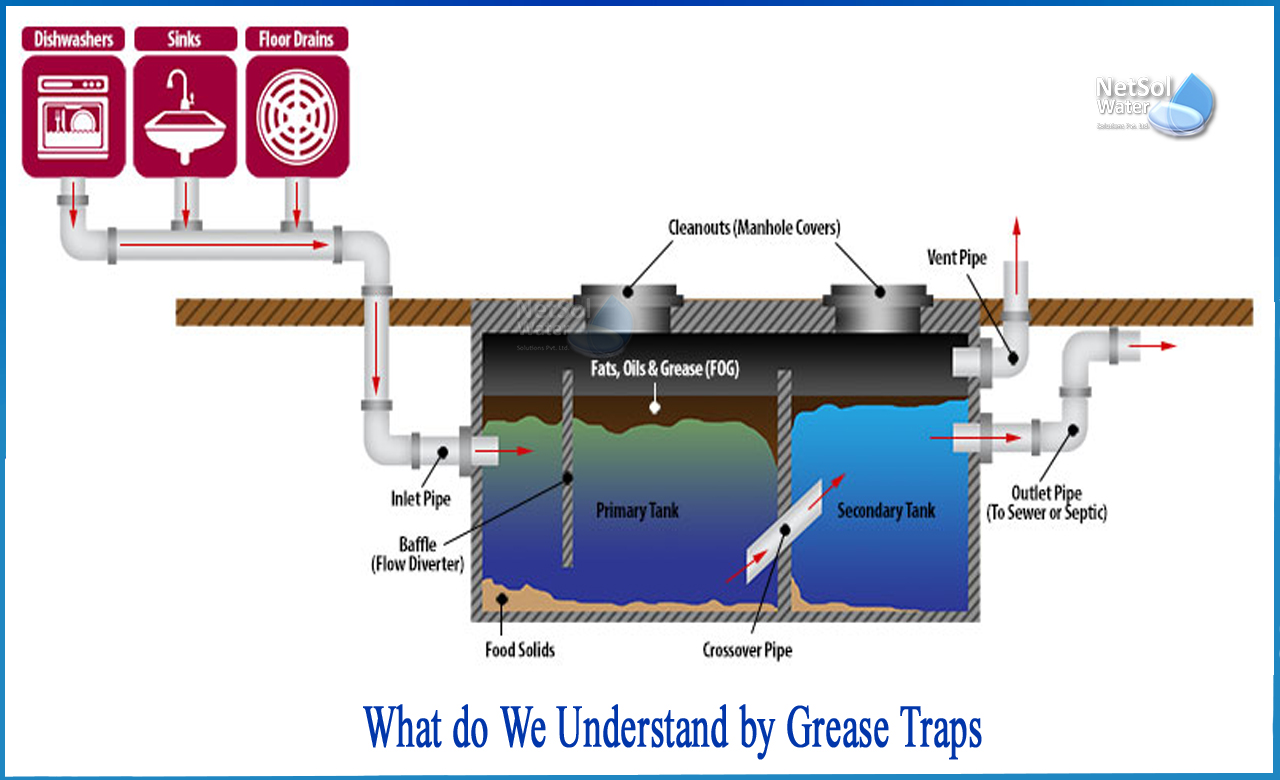

To put it simply, a grease trap is a container through which FOG-containing wastewater flows before entering a drainage system. The receptacle is intended to catch or "trap" the FOG while allowing clear water to escape.

What do we understand by grease traps?

A grease trap's purpose is to collect and thus reduce the amount of fats, oils, and greases (FOG's) that enter the main sewers. Grease entering the main sewer system will cause blockages, foul odors, and pest infestations over time. Grease traps, which have been in use since long, are simply boxes that are placed within the wastewater drain that runs from the sinks and appliances in a kitchen to the foul sewer system. They are only intended to receive wastewater from the kitchen and should never receive wastewater from other drainage system sources such as toilets.

What is the purpose of a grease trap?

Grease discharged into sewers clogs pipes and impairs the performance of sewage treatment plants. Grease traps must be installed wherever fats and greases are discharged into the drainage system.

The use of 'enzymes' to dissolve grease in wastewater is insufficient because it results in grease reforming further down the sewer. Grease/oil will then separate from the wastewater due to specific gravity, ensuring that the wastewater discharged into the sewer is grease-free according to normal discharge standards.

Grease traps operate on the premise that FOGs float on water while solid particles sink. The trap's baffles slow the inflow of wastewater from the kitchen sinks. This allows for a period of adjustment during which oils, water, and food particles separate within the unit. A trap on the outlet prevents FOGs from flowing directly through the unit, allowing cleaner water to flow through while the FOGs are retained within the unit along with food particles. The retained waste will accumulate over time, necessitating regular servicing and waste removal for environmental disposal.

How efficient are they?

A grease trap's effectiveness is determined by a variety of factors, including design, kitchen location, drainage systems, size, and kitchen practice. Every location and circumstance is distinct. On average, a single stage grease trap will retain between 50% and 90% of the FOGs that enter it. The majority of commercial grease traps have a single chamber. To improve the efficacy of grease control and management, two or more units can be used in tandem, with each unit or chamber separating between 50% and 90% of the FOGs that enter it. Alternatively, a single stage grease trap can be aided by the installation of a biological grease dosing system.

Types of Grease Traps

Grease traps are classified into three types: passive hydro mechanical (manual), automatic, and gravity.

1: Grease traps that are passive hydro mechanical (manual)

Traditional passive systems are among the most common in smaller establishments. This is because of the low initial investment required to purchase one, as well as the variety of sizes available, which means they can be easily installed under most sinks, while larger units are available to accommodate larger wastewater production requirements.

2: Grease traps that operate automatically

Automatic systems, also known as AGRUs (automatic grease removal units), use some of the same principles as traditional passive traps but automatically re-heat and skim out the FOG on a predetermined schedule. The FOG that has been skimmed is then transferred to a collector bin for easy removal and recycling. The programmed schedule is based on the amount of FOG produced, which eliminates the need for operators to measure or check grease levels.

3: Grease traps based on gravity

Gravity systems are typically large in-ground tanks made of concrete, fiberglass, or steel. They function similarly to passive hydromechanical traps, but have a much larger capacity and are better suited for high-flow applications. Gravity traps must be pumped out on a regular basis, which is usually done by a grease management service company.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.