Waste Water and Sewage Water problem in Gurgaon (Gurugram), Causes and Impact on health

Gurgaon has been facing severe wastewater and sewage problems for years now. Rapid urbanization and population growth have put immense strain on the outdated and inadequate sewage infrastructure. As a result, large quantities of untreated sewage flow on the streets and stormwater drains, turning parts of the city into giant cesspools. The main factors contributing to this public health hazard are - the lack of sufficient sewage lines to cater to the rapidly increasing population, poorly planned sewerage systems, inefficient treatment plants, and rampant illegal discharge of wastewater from residential and commercial establishments into open drains. Many areas rely on septic tanks, which often overflow and further aggravate the problem.

There are several impacts of this gross mismanagement of sewage and wastewater. The foul odor and sight of overflowing drains filled with sewage make open defecation and urination familiar. This leads to the spread of bacteria, viruses, and parasites through contamination of drinking water. Jaundice, typhoid, diarrhea, cholera, and other water-borne diseases peak during the monsoon season when potable sources mix with sewage. Skin infections are also widely prevalent.

The situation is exacerbated during the rainy season as stormwater mixes with sewage, triggering floods of disease-ridden filthy water. Groundwater resources get contaminated, further threatening the health of people relying on borewells and tubewells—vermin breeds in the overflowing drains, spreading more diseases. Overall, the wastewater problem has increased the health risks manifold for Gurgaon residents. To tackle this ominous issue, civic agencies need urgent upgradation and expansion of drainage and sewage networks to match population growth. Strict monitoring of discharge from residential and commercial premises and heavy penalties for violations are essential. Investments in advanced wastewater treatment plants can help recycle wastewater, which can relieve some pressure on freshwater demand. Without such concrete and prompt action, the wastewater crisis threatens to turn Gurgaon from a modern city into an urban nightmare plagued by disease and contamination.

What is the groundwater quality in Gurgaon?

Gurgaon, renowned as a symbol of India’s rapid economic growth in recent decades, is facing an invisible health hazard lurking below its shiny exterior – deteriorating groundwater quality. Years of unchecked development and exploitation of groundwater resources to satisfy freshwater demands of industries, businesses, and its growing urban population have left its aquifers contaminated.

Several reports have found the presence of high concentrations of nitrates, salinity, heavy metals like lead and cadmium, and bacterial contamination in Gurgaon’s groundwater. Sources of contamination include untreated sewage from residential areas and industries entering aquifers, over-extraction, improper waste disposal, and excessive use of chemical fertilizers for agriculture. A study by a medical college showed 87% of water samples from Borewells failed quality tests, making it unfit for drinking and raising severe public health issues.

This has profound health implications for Gurgaon’s residents as significant parts of the city depend on groundwater to meet their daily requirements. Contaminated water increases the risk of water-borne diseases like cholera, diarrhea, jaundice, typhoid, etc. Nitrates induce blue baby syndrome in infants. Lead accumulates in the body, affecting kidneys and causing developmental issues in children. The crisis remains invisible as groundwater pollution, being a sub-surface issue, is often ignored until problems surface. Addressing this requires strict regulations on overexploitation of groundwater, mandatory treatment of industrial effluents and sewage before discharge, and heavy penalties for violations. Low-cost solutions like rainwater harvesting, groundwater recharge initiatives, and proper waste disposal measures are imperative to improve aquifer health. The authorities also need to regularly monitor groundwater quality and spread awareness on taking necessary precautions for usage till remedial actions are implemented. Tackling this hidden hazard must be on top of Gurgaon’s urban governance agenda before the situation worsens.

Why water logging is there in Gurgaon?

Gurgaon, located in the NCR region, has witnessed tremendous real estate development over the last 15 years. From a fledgling township, it has emerged as a major corporate hub and houses offices of several 500 companies. However, this uncontrolled urbanization has extracted costs – waterlogging being the most notorious one haunting the city every monsoon.

Reasons for Waterlogging: Multiple factors have combined to make waterlogging an annual headache in Gurgaon as analyzed below:

1- Flat Topography: Large parts of Gurgaon have very flat ground profiles without adequate slopes for streamlined drainage of stormwater. This inhibits the gravity-assisted flow of accumulated rainwater into natural streams or stormwater drains. Flat terrain also raises the groundwater table, reducing natural absorption.

2- Unplanned Construction: The breakdown of construction of buildings, roads, and flyovers has happened unplanned without the provisioning of water drainage and harvesting systems. Green zones across the city have been extensively concretized, preventing underground percolation. Stormwater drains were not designed considering enhanced peak loads.

3- Encroachments: Many original water channels and village ponds, which earlier absorbed excess rainfall, have been infringed upon for real estate development. This has severely disrupted the natural drainage patterns across regions.

4- Inadequate Drainage: The original drainage lines have been densely interconnected but cannot handle peak rain intensity. Stormwater drains cannot keep pace with the concretization of open land, reducing natural catchment areas. Plastic waste clogging and silt deposits further reduce carrying capacity.

5- Uncollected Waste: Plastic, metal and construction debris dumped on roads and open spaces causes choking of water flow through drainage lines, worsening accumulation. The absence of garbage screens means existing drains get clogged after heavy rainfall.

6- Loss of Green Cover: Reduced green cover and loss of water bodies imply rainfall is not intercepted/contained locally through absorption into the ground before it can collect downstream. The decline of Gurgaon’s Aravalli forest cover and pollution of Najafgarh Jheel have diminished natural water sinks.

Solutions Recommended:

Multiple remedial steps are imperative across the short and long term to alleviate Gurgaon from this recurring nuisance:

1- Improved Drainage The priority is to enhance network capacity by restructuring and redesigning key stormwater channels. Widening narrow sections and installing pumping stations at critical waterlogging hotspots can help overcome hydraulic limitations.

2- Smart Water Drainage: Several advanced solutions like real-time drainage monitoring sensors, automated pumping controls and remote-controlled underground reservoirs with large storage capacity can overcome infrastructure constraints intelligently today.

3- Waste Management: Strict anti-littering laws, screening mechanisms to filter plastic debris, and regular desludging must be enforced to prevent the choking of drains. Planned construction waste hauling would curb haphazard dumping.

4- Reviving Water Bodies: Steps like preventing the discharge of sewage/industrial effluents into ponds/lakes and developing catchment areas through deconcretization of their banks would help restore natural absorption. Dredging and pollution mitigation activities would help considerably.

5- Afforestation: Efforts Large-scale planting of native trees alongside existing water bodies is necessary to rejuvenate green cover. Their deep roots and moisture absorption capabilities aid in replenishing underground aquifers.

Gurgaon’s early haphazard development has led to recurring waterlogging but corrective action through improved drainage networks, waste management and ecosystem restoration measures can help overcome the problem. A combination of administrative strictness and infrastructural revamp is the need of the hour.

What is sewage treatment plant and How it is helpful to solve water issues in Gurgaon?

Gurgaon, the sprawling corporate hub on the outskirts of New Delhi, has seen tremendous real estate development over the last two decades. However, rapid urbanization has heavily pressured civic infrastructure, especially water supply and sanitation systems. Lack of sewage treatment has led to the discharge of untreated effluents into open drains like the Najafgarh drain, contaminating limited freshwater resources available. Installation of sewage treatment plants can help ease this water stress significantly through recycling.

What is a Sewage Treatment Plant?

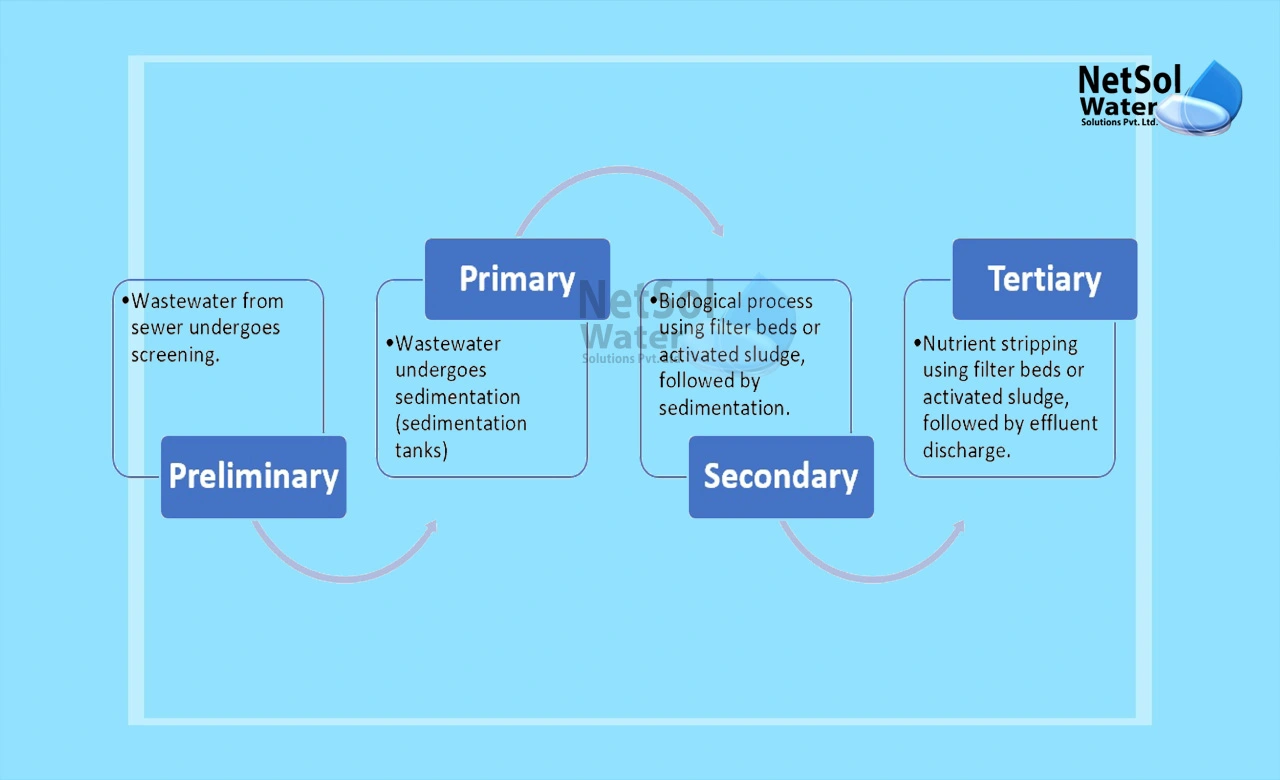

A sewage treatment plant (STP) is a facility designed to receive wastewater from residential, institutional and commercial buildings and remove contaminants to restore it to acceptable pollution levels before environmental discharge or reuse. Treatment technologies utilize physical, biological and chemical processes to remove suspended solids, organic matter, nutrients, disease-causing organisms and other impurities. Treated wastewater can be safely discharged into water bodies or reused thus enhancing sustainability.

Treatment Stages

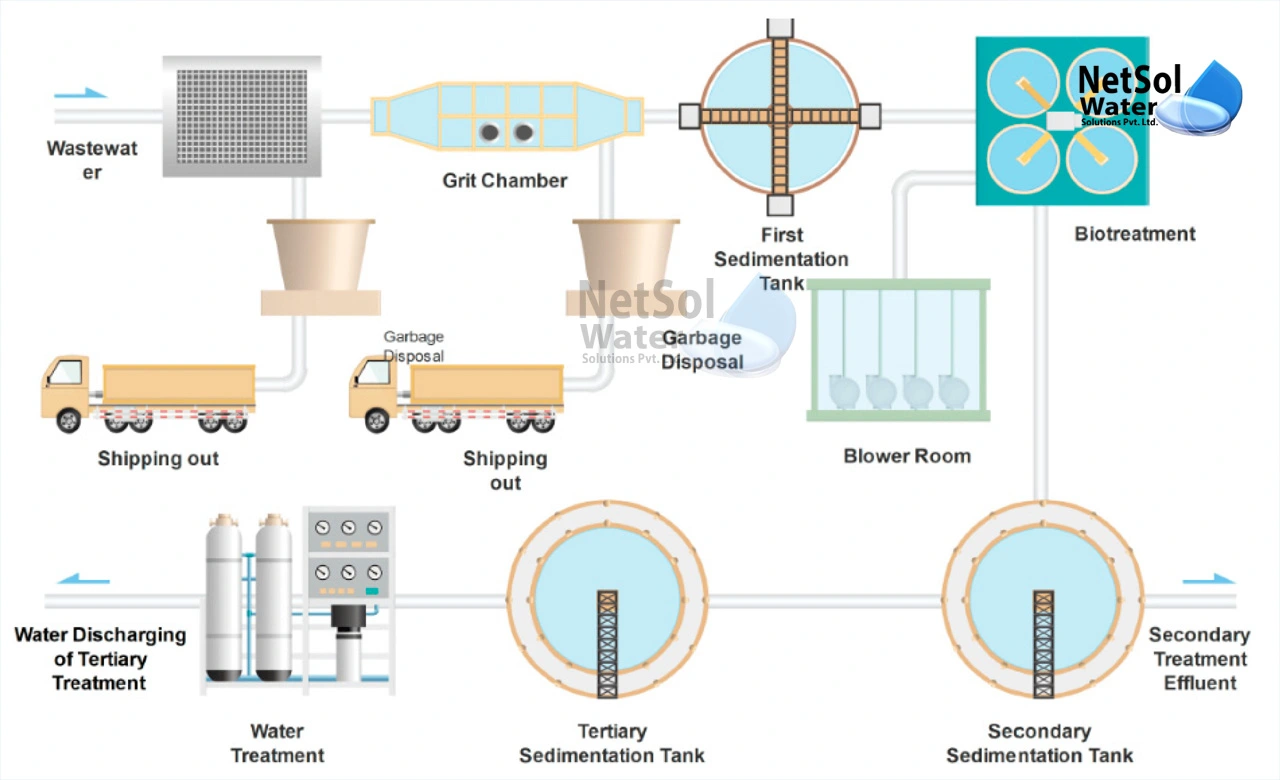

STPs involve multiple stages: preliminary screening to remove coarse particles, primary sedimentation, secondary aerobic biological treatment to degrade organic impurities, and disinfection. Conventional activated sludge processes, trickling filters, SBR, MBBR and MBR technologies with necessary tertiary treatment can be employed based on sewage characteristics.

Helping Solve Gurgaon’s Water Woes

Recycling even 20% of the estimated 300 million liters per day (MLD) of sewage generated in Gurgaon through well-designed STPs can meet non-potable water needs in buildings to reduce significant groundwater exploitation. Treated sewage can replace fresh water for flushing, cooling tower make-up, landscaping, and street cleaning. The end outcome is a sizable drinking water conservation that should be strictly reserved for direct human consumption.

Strict compliance enforcement of sewage treatment rules by the Haryana State Pollution Control Board and advanced wastewater technologies can transform sustainability in Gurgaon through next-generation urban water management.

Sewage treatment infrastructure plays a vital role in enhancing water security by recycling millions of liters daily safely to relieve pressure on limited pure water reserves. Widespread adoption of efficient STPs with tertiary treatment is central to Gurgaon managing its water needs sustainably for the future.

Working process of the sewage treatment plant and What are the treatment stages?

Sewage treatment plants (STPs) are complex facilities designed to filter impurities from municipal wastewater before they are safely released into the environment. Raw sewage passes through several rigorous cleansing phases in an STP to remove solids, dissolve oxygen, kill pathogens and reduce chemical pollution through biological and physical processes.

Initially, screening is done to filter solid objects like rags, plastics, etc. Large solids may damage treatment equipment. Next, sedimentation tanks allow suspended particles to settle at the bottom, forming sludge, which is removed. The liquid then goes into aeration tanks where oxygen is pumped and mixed with microbes to break down and consume organic compounds in a biochemical oxygen demand (BOD) reduction phase.

This digestion via an activated sludge process converts ammonia to nitrates (nitrification), facilitating algae and bacterial growth removal later. The mixture then flows into secondary settling tanks for clarification, where cleaned water separates from activated sludge microbes, which are recycled into aeration tanks. Further filtration and disinfection are done through sand filters, chlorine or ultraviolet rays to kill remaining bacteria and viruses.

Finally, the treated water with reduced solids, BOD and pathogens can be discharged into water bodies or diverted for non-potable uses like irrigation according to pollution control norms. The separated solids or sludge produced during multiple stages is further processed to be reused as fertilizer, incinerated or disposed of safely in landfills.

This stepped treatment allows STPs to thoroughly decontaminate millions of liters of sewage daily by following standardized purification procedures. However, maintaining the functioning of all equipment via skilled personnel is equally vital for STPs to keep treating sewage effectively and mitigate environmental risks.

Which technology is to be used by sewage treatment plants to treat the water and wastewater?

Sewage treatment plants employ various unique technologies powered by biological, chemical and physical processes to remove contaminants from millions of liters of wastewater daily before safe discharge/reuse.

Preliminary treatment begins using bar screens, grit chambers and clarifiers to filter out large debris and sediment via gravitational settling. Primary sedimentation then allows suspended solids to sink for easy removal while oil and grease float up for skimming due to density differences.

Secondary biological treatment is the most vital stage, where oxygen is dissolved into clusters of aerobic microorganisms like bacteria in aeration tanks to consume organic matter. This activated sludge process converts ammonia into nitrate via nitrification, achieving Bod/COD reduction through microbial digestion. Oxygen levels, temperature, and pH are optimized to accelerate the breakdown of impurities.

The tertiary treatment uses sand, coal or activated carbon filters to trap fine particles missed earlier and further disinfect water. Advanced methods like membrane filtration (ultrafiltration, reverse osmosis, electrodialysis) help extract dissolved compounds via diffusion through semi-permeable membranes. Chlorine, ozone or ultraviolet irradiation introduces the final stage of chemical/radiation disinfection, demolishing pathogenic microbes for water safe for discharge or reuse for flushing, gardening, etc. Treated sludge is further processed with digestion tanks, centrifuges, and filter presses to generate byproducts like biogas.

Automation with Programmable Logic Controllers and Remote Telemetry allows centralized monitoring, optimizing operational efficiency. Continued technology upgrades like Moving Bed Biofilm Reactors, MBBRs (hybrid bacterial cultures) or Integrated Fixed-Film Activated Sludge, IFAS (biofilms on support media) can enhance treatment capacity and eco-friendliness allowing STPs to treat ever-rising volumes of wastewater sustainably.

What are the consumables in STP plants and what are the cost of consumables?

Sewage treatment plants rely on various chemicals and materials to facilitate the complex purification processes of daily cleaning of millions of liters of municipal wastewater. These vital consumables help maintain optimal operations, and their procurement amounts to a significant share of an STP’s regular running costs. Disinfectants like chlorine, sulfur dioxide, and ultraviolet systems are used during pre and final treatment stages to suppress microorganisms and prevent biofouling of equipment by algae/bacteria. Chlorine is fed in measured dosages into inlet flows or applied as sodium hypochlorite during the filtration and clarification stages. Other oxidizing biocides include bromine and hydrogen peroxide.

Polymers like anionic PAM (polyacrylamide) and cationic PAC (poly aluminium chloride) are vital to expedite the flocculation and coagulation processes, allowing the separation of suspended particles from wastewater. Inorganic coagulants like ferric chloride or polyelectrolytes also facilitate sedimentation, thickening of excess sludge and dewatering.

Nutrients like nitrogen and phosphorus are carefully supplemented in controlled concentrations to accelerate the aerobic digestion of organic matter and regulate micronutrient levels for optimal microbial activity during biological treatment. Maintenance consumables like lubricants and spare parts (pumps, pipelines) are routinely required.

On average, the annual operating costs for treatment chemicals, energy/power and solid waste handling can amount to nearly 50% of total expenditure for STPs with capacities above 100 MLD (million liters daily). Capital and labor account for the remainder. Rising chemical prices and greater automation are also driving up operational costs, which impact sewage treatment charges levied by civic bodies.

What kind of chemicals are used in STP plants to treat the water and does this chemical have impacts on human health?

Sewage treatment plants employ various chemicals to remove contaminants and purify wastewater during the multi-stage treatment process. Commonly used chemicals include:

Coagulants and Flocculents:

Coagulants like alum, polyaluminium chloride and ferric salts are added to raw sewage to destabilise colloidal particles and aggregate suspended matter to form flocs which settle out quickly. Anionic/cationic flocculents aid this floc formation.

Disinfectants:

Chlorine, sodium hypochlorite and chlorine dioxide act as disinfectants, killing disease-causing microorganisms like bacteria before the treated sewage is discharged safely into the environment.

Acids and Alkalis:

Acids (sulphuric acid) and alkalis (sodium hydroxide) are used for pH correction at different stages to maintain optimal conditions for biological treatment processes.

While most chemicals are removed substantially before the discharge of final treated effluent, some residual traces may remain along with disinfection by-products like trihalomethanes, which have health risks if found above permissible limits.

Potential Health Impacts

The presence of traces of metals like aluminum or iron can lead to neurotoxicity upon prolonged exposure. Inadequate chlorine dosing may result in pathogenic microbes not getting fully inactivated. Many disinfection byproducts are carcinogenic and can cause problems like liver and kidney damage and reproductive issues. Some studies have linked chlorine usage to increased cancer risk.

Mitigating Risks

Modern-day STPs have automatic dosing systems with continuous feedback loops to inject precise optimum levels of specific chemicals as per influent wastewater characteristics. This prevents indiscriminate use. Additional technologies like ozonation are employed to avoid byproducts associated with chlorine while disinfecting sewage. TERI has developed an innovative microbe-based cleantech for sewage treatment, avoiding chemicals altogether while meeting discharge standards through a natural approach.

Strictly following safety protocols and exposure limits prescribed by environmental agencies can help mitigate occupational health hazards. The adoption of fully automated STPs further reduces human intervention and contact. Avoiding the discharge of untreated sewage into freshwater bodies also prevents health risks to the general population dependent on the same water resource.

In summary, most chemicals utilized during sewage treatment are highly diluted, but some potential health impacts may still arise upon direct exposure. Advances in treatment methods, automation technologies and strict adherence to safety limits is essential to ensure long-term welfare while allowing STPs to recycle sewage safely.

What is the need to install the STP plants in Gurugram and What area is required to install the STP plants?

The rampant discharge of untreated sewage into open drains and water bodies has created alarming water pollution levels in Gurugram. As the city’s population swelled from just 0.25 million in 2001 to over 2.5 million in 2023, the civic agencies failed to expand sewage treatment capacities, thereby allowing unchecked dumping of over 150 MLD (million liters per day) of untreated sewage generated daily into the Najafgarh Drain basin.

This severe neglect has manifested into a significant public health and environmental crisis for the city, with reports consistently highlighting the presence of toxic E. coli bacteria in groundwater samples at concentrations 150-200 times the permissible limit set by the Bureau of Indian Standards. Fecal coliform counts have also soared beyond safe levels in village ponds. Yamuna river water in Delhi down the Najafgarh drain contains zero dissolved oxygen due to sheer volumes of organic sewage dumps from Gurugram.

Correcting decades of administrative apathy requires investments into a comprehensive network of sewage treatment plants nationwide to filter hazardous contaminants before water can be released back into nature or reused if safely treated per pollution control guidelines. Expert estimates indicate that to fully treat the 300+ MLD sewage generated daily along with sufficient capacities for the future population surge towards 5 million by 2031, Gurugram needs over 15 STPs with individual capacities between 25-60 MLD based on catchment areas.

The allocation of 15-20 acres of land per STP is also vital depending on the technological configurations, such as conventional activated sludge process models or advanced ultrafiltration systems. Sites need to be strategically scouted near main residential zones to minimize sewage transfer costs via pipelines. The Haryana government has an outlay of Rs 1300 crores for new STPs but faces land acquisition challenges similar to those of other urban infrastructure projects.

While installing such capital-intensive, large-scale treatment plants is a complex, lengthy undertaking, Gurugram is left with no other recourse to control worsening health hazards from its heavily contaminated water if it has to restore the fundamentals supportive of life for its citizens and the environment.

What are the compliance requirements to install an STP plant in Gurgaon?

Sewage treatment plants form the crucial backbone supporting sustainable water reuse across urban agglomerates like Gurgaon, which are struggling with severe contamination of natural water bodies due to the discharge of untreated sewage. However, establishing an STP demands strict adherence to environmental compliances, from planning to execution, monitored by pollution control boards.

Consent to Establish under Water Act, 1974

The foundation for regulatory approvals begins with securing Consent to Establish (CTE) from the Haryana State Pollution Control Board (HSPCB) under the Water (Prevention and Control of Pollution) Act, 1974, which governs the discharge of sewage and effluents. The CTE application must cover details like the type of facility, installed capacities, treatment technologies used, site plans, disposal methods, and the processing fee.

The CTE approval stipulates timelines for completion, volume of sewage to be handled and permissible standards for the treated effluent quality before final disposal into surface water bodies or the sewerage system. These discharge levels are determined as per highly stringent pollution norms. It also specifies penalties if untreated sewage discharge limits are exceeded. The CTE has to be renewed if stipulated construction timelines are not met.

Environment Clearance

STPs with capacities above 100 kilolitres per day (KLD) also require prior Environmental Clearance from the Ministry of Environment, Forest and Climate Change facilitated by the State Environment Impact Assessment Authority. The application furnishing planned capacities, water consumption patterns, impact forecasting reports, and environmental management plans are reviewed by expert committees before EC is awarded if they are found satisfactory.

The EC stipulates elaborate pollution control mechanisms compliance during the operational phase, including duties like periodic monitoring of water quality, maintaining treatment efficiencies, and ensuring zero untreated sewage discharge. The approvals also hold legally binding should non-compliance arise.

Municipal Corporation Approvals

Submitting copies of the CTE and EC to the Municipal Corporation is necessary to seek approval sanctions to draw water supply, connectivity to the sewerage network pipeline infrastructure and land use permits for site development.

Other Compliances

1- Consent to Operate before commissioning STP

2- Authorization under Hazardous Wastes Rules for sludge disposal

3- Submissions of water samples report to HSPCB during ops

4- Logbooks of operation parameters and chemical consumption data

5- Online continuous effluent monitoring system to transmit real-time data

6- Weatherproof daily display of the effluent analysis test results, flow meters

7- Emergency response plan for plant shutdowns due to electricity failure

8- Membership to TSDFs for hazardous waste disposal

Evolving a compliance framework spanning project approvals to daily functionality necessitates investing time and resources. But strict adherence transforms STPs into law-abiding, legitimate establishments producing effluent discharges meeting all quality criteria, preventing environmental risks due to sub-standard operations—a blessing for water bodies under distress.

How do you calculate the capacity of STP plants and share the Calculations?

The capacity of a sewage treatment plant (STP) refers to the amount of sewage it can effectively process in a day measured in million liters daily (MLD). Designing adequate treatment capacity is vital for meeting a city’s current sewage generation rates and expected future loads. Undersized STPs result in the discharge of untreated sewage, while overestimation leads to locked investments.

The step-wise process for determining appropriate STP capacity for a town, city, industrial facility or residential complex incorporates scientific analysis of multiple dynamic variables and forecasting growth rates.

Quantifying Current Sewage Generation

The first step calculates the existing sewage generated from a designated area. This depends on:

1- Population - Current and floating population to be served in the STP catchment area

2- Water Supply Rate - Per capita supply rate helps deduce sewage produced

Water consumption data can be obtained from municipal authorities. As a rule of thumb, 80% of water supplied is discharged as sewage.

Per Capita Sewage Production = Water Supply Rate * 0.8

For example, if the water supply rate = 220 LPSD (liters per person per day), Per capita sewage = 220 * 0.8 = 176 LPSD

For a population of 500,000: Total Sewage = Per capita sewage x Population = 176 x 500,000 = 88 MLD

The per capita sewage production rate generally lies between 135 and 170 LPSD for Indian metropolitan cities. WHO recommends 120-150 LPSD.

Estimating Future Sewage Loads

The second key step forecasts sewage generation rates for at least a 20-30-year period. This accounts for population growth and improves the standard of living, which enhances per capita sewage production.

Factors impacting future sewage discharges:

1- Population Growth Rate as per census - 2-6% per annum

2- Floating Population

3- Emerging Trends - Lifestyle changes, water-intensive appliances

4- Sewer Connections Coverage - Extending piped connections increases collected sewage volumes supplied to STP

5- Applying growth multipliers to current sewage rates gives the design capacity:

Future Sewage Generation = Current Sewage Generation X Growth Multiplier

For example, with 4% annual growth over 20 years: Future sewage = 88 MLD X (1+0.04)^20 = 215 MLD

Thus, for 20 years, providing a design capacity of 250 MLD with room for overload is ideal.

Land Requirements

The STP land area depends on the process design, hydraulic loads and allied infrastructure:

1- Treatment methods - Activated sludge process, trickling filter, SBR

2- Utilities - Power supply, pumping stations

3- Testing Labs

4- Administrative Buildings

As a general guideline, conventional STPs require ~ 0.05 to 0.1 hectares per MLD capacity. So, for 250 MLD plants, 12 to 25 acres are needed. More land allocates scope for further expansions.

In summary, determining STP capacities involves methodically - quantifying current sewage volumes based on water-supplied data →, predicting future loads from population growth trends →, providing an additional buffer of 15-20% for overloads, → factoring process land requirements for constructing a sustainably scaled treatment facility. Robust initial capacity planning thus ensures the STP reliably serves the area's needs for decades while scaling up capacities along the trajectory of a city’s increasing waste footprint.

ROI of installation of STP plants in Gurgaon

With rapid urbanization over the decades without matching sanitation infrastructure upgrades, Gurgaon typifies the paradox of economic growth absent sustainability planning. Once pristine lakes have transformed into toxic cesspools due to direct inflows of untreated sewage totaling over 300 MLD daily. Rectifying decades of administrative neglect now warrants the urgent installation of advanced sewage treatment plants, even as authorities grapple with land acquisition issues and financing challenges given the massive capital expenditure totaling ~?2000 crores needed as per estimates. However, a focused cost-benefit analysis reveals that investments into STPs, while substantial, are justified given the significant ROI from both cash savings and positive externalities.

Tangible Cash Inflows

1- Revenue from treated wastewater usage – An 85 MLD STP with tertiary treatment can supply ~68 MLD recycled usable water daily worth ~?6.5 crores annually to industry and agriculture for significant freshwater substitution at commercial rates.

2- Savings from preventing groundwater contamination – With STPs eliminating sewage outfalls, groundwater quality will gradually improve, thus saving expenditure of ~?100 crores on alternative piped water imports proposed by civic agencies. This enhances natural capital.

3- Energy generation from sludge – An 85 MLD STP can generate ~1 crore units of electricity yearly through anaerobic digestion of 10 tonnes of surplus sludge produced daily, creating an annual value of ?5 crores.

4- Fertilizer Production - The nutrient-rich processed sludge is an excellent soil conditioner that can generate ~?3 crores in annual revenues for the municipal body.

Total Cash Inflow = Water Sales + Groundwater Savings + Energy + Fertilizer revenues = ?15.5 crores per 85 MLD STP per year

Intangible Benefits

1- Improved Health & Living Standards - Safe water reuse for non-potable needs, groundwater decontamination reduces water-borne diseases, improving public health indices. Addresses National Clean Water Mission goals.

2- Environmental Quality - 84 MLD less sewage discharges will reduce Gurgaon’s entire biological oxygen demand load by ~30%, improving air and water quality and enabling ecology regeneration.

3- Project Image Enhancement – STPs signal ecological consciousness and position the city as an attractive destination for industries and talent with long-term sustainability planning trailblazing water conservation.

Considering the capital investment of ?250 crores for 85 MLD STP capacity yields:

ROI Period = Total Capital Investment / Annual Cash Inflows = ~16 Years

Since most STP infrastructure operates sustainably for 30-40 years, investing allows the city to reap cash and health dividends while reversing decades of environmental damage through improved sewage management. The 16-year ROI further shrinks considering additional annual O&M, land and depreciation costs. Despite capital constraints, Gurgaon must prioritize investments into STPs as the first step towards restoring aquatic health.

Why has it now become necessary in Gurgaon to install an STP plant?

Gurgaon, located in the National Capital Region of India, has seen rapid urbanization and population growth over the last two decades. From a small town, it has transformed into a major corporate and financial hub, attracting migrants from across India. This unchecked and unplanned growth has put immense strain on civic infrastructure, especially the management of sewage and wastewater.

The city produces over 300 million liters of sewage per day but cannot treat even half of it through Sewage Treatment Plants (STPs). Much of this untreated sewage is discharged into local drains and empties into the Najafgarh drain. This poses serious health and environmental hazards - contamination of groundwater and surface water bodies being the major ones. Several studies have reported high levels of nitrates, bacteria, and heavy toxic metals in Gurgaon's water bodies. Last year, the National Green Tribunal pulled up the Haryana government and its agencies for failing to process sewage discharged in the Najafgarh drain adequately.

This worsening water pollution and its risk to human health has made installing STPs necessary in Gurgaon. STPs treat sewage through mechanical, biological, and chemical processes to produce environmentally safe fluids for disposal or reuse. Scaling up sewage treatment infrastructure is vital to improving the environmental conditions and preventing diseases in the city. The Haryana government has made STP installation mandatory for all residential and commercial establishments discharging sewage above a minimum threshold. Stringent timelines, penalties and creative solutions like modular STPs have also been introduced, considering the severity of the situation. Proper treatment of all sewage discharged is the only way Gurgaon can restore its fast-degrading environment. Implementing these norms and regular monitoring after that is the need of the hour.

The health of Gurgaon's residents and ecosystems depends directly on the robustness of its sewage treatment infrastructure. The time has come for the city to make amends and move towards responsible and sustainable urban development.

How to choose the best sewage treatment plant manufacturer in Gurgaon.

With rapid urbanization and population growth, Gurgaon generates over 300 million liters of sewage daily. The lack of proper wastewater treatment has led to severe contamination of water bodies in the region, necessitating the urgent installation of sewage treatment plants (STPs). Choosing a reliable and experienced STP manufacturer in Gurgaon is crucial to ensuring your plant operates efficiently in the long run

Need for Customized Design

An essential first step is determining the daily sewage output volume and inlet quality parameters like BOD, COD, TSS, etc, for your residential society, commercial building or industry. STP technology and capacity are then chosen accordingly to meet pollution control board discharge norms.

Reputed manufacturers like Netsol Water will customize the STP design for your sewage treatment needs rather than taking a one-size-fits-all approach. They adopt conventional, MBBR, SBR, or hybrid technologies based on your application. Advanced 3D modeling software is used to simulate real-world conditions and fine-tune the STP layout.

Operational Expertise

Look for an STP manufacturer possessing over 15 years of expertise in executing projects across various scales – from 50 KLD systems housing societies to 5000 KLD plants for large communities. The company must have an in-house team comprising process engineers, mechanical engineers, technicians, etc, to design and execute turnkey STP projects. Ensure they offer comprehensive Operation and maintenance services for at least 5 years and annual maintenance contracts. This ensures that their service team promptly addresses any issues during treatment process stabilization or equipment breakdowns.

Plant Automation

Reputed Gurgaon STP manufacturers like Netsol Water will incorporate a high degree of plant automation for ease of operation and require no manual intervention. This includes PLC-based control systems for equipment operation, SCADA interface for remote monitoring and Android/Windows/Web applications for tracking real-time plant performance.

Automated features like automatic motor reversal for screen/grit removal, nutrient dosing pumps, decanters and sludge dewatering systems minimize human effort. SMS/email alerts notify officials about any abnormal plant conditions for timely troubleshooting.

Quality & Reliability

Choose an STP OEM that has ISO 9001 certification for its quality management practices. Ensure they use premium quality components. All structures are FRP-lined for corrosion resistance and have a minimum 5-year anti-percolation warranty.

Only shortlisted manufacturers who clear stringent technical criteria concerning experience, plant performance and support capabilities should be considered. You can request client references from similar STP projects to verify their capabilities.

After-Sales Support

Timely after-sales support is vital for STPs to cope with sudden sewage quality/quantity changes. Choose an STP company having a Gurgaon regional office with a large warehouse for ready inventory of parts like media, membranes, pumps, etc.

Quick turnaround for repairs/replacement through resident engineers must be assured. Specialized teams must be available for attending breakdowns or undertaking annual plant audits/performance reviews.

Financial Strength

The STP manufacturer must have strong financial backing and business expertise. They should offer flexible financing options for capital purchases, O&M charges, along with annual maintenance contracts.

Exposure to Latest Technologies

Look for STP companies collaborating with international technology providers in biological/MBBR/SBR treatment processes. They must showcase full-scale plants implemented using ultrafiltration and reverse osmosis modules for effluent recycling applications.

Association with leading research institutions keeps them abreast of newer innovations in this field, leading to better offerings.

Leading Sewage Treatment Plant Manufacturers in Gurgaon (Gurugram)

Some leading names offering customized STP solutions in Gurgaon, along with their key focus areas, are highlighted below:

1- Netsol Water - Specialists in conventional activated sludge process and tertiary treatment plants.

2- Sewage Treatment Plants – Pioneers in decentralized, modular STPs with automated operation.

3- Compact STP Plant – Leaders in integrated sewage treatment solutions using advanced MBBR technology.

4- Compact ETP Plant – Providers of odour-control and cost-effective STP systems on a turnkey basis.

5- Biotech India – Offers end-to-end bio-remediation solutions for lake restoration.

Installing a reliable STP customized to handle fluctuating sewage loads is crucial for housing societies and commercial complexes. Partnering with an experienced STP manufacturer with proven design and execution capabilities, strong service support, and financial backing is vital.

How sewage treatment plant manufacturer is helping to solve the water problem issues in Gurgaon?

Gurgaon produces over 300 million liters per day of sewage through residential complexes, commercial buildings, and industrial units. Historically, the city lacked adequate infrastructure to treat this massive volume of wastewater. As a result, untreated sewage has been discharged into open drains like the Najafgarh drain and finally flows into the Yamuna River. The city's water bodies became extremely polluted, posing severe public health and environmental hazards.

Recently, the Haryana government has made sewage treatment mandatory before being discharged into public drains. Stringent norms have forced Gurgaon's societies, developers, and corporations to install in-house sewage treatment plants (STPs) to treat water to permissible discharge standards. This has created substantial demand for reliable STP manufacturers and operators in the region.

Customized Plant Design

Reputed STP manufacturers in Gurgaon offer technically optimized solutions customized to handle specific sewage output and quality parameters. Their in-house design teams study inlet characteristics like Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Total Dissolved Solids (TDS), pH, etc, before recommending appropriate treatment technology and capacity. Plants are designed to meet the treated sewage standards laid down by the Haryana State Pollution Control Board (HSPCB) for safe disposal into the public sewage network.

Advanced Treatment Technology

Modern STPs incorporate advanced technologies like Moving Bed Biofilm Reactors (MBBR), Sequential Batch Reactors (SBR), Membrane Bio-Reactors (MBR) etc. These ensure consistent treatment quality necessary to meet the stringent discharge norms specified by the pollution control board. Fully automated operation through PLC-SCADA systems minimizes manual intervention. Features like remote real-time plant monitoring, preventive alerts, automated chemical dosing, and decanters optimize overall plant performance.

24x7 Service Support

Reputed STP companies have Gurgaon regional offices with trained service engineers always on standby. Any equipment faults or media clogging issues in the plant are attended to urgently, ensuring minimal plant downtime. Periodic plant audits help optimize biological treatment through necessary media replacement or equipment upgrades. The manufacturers also offer comprehensive Annual Maintenance Contracts (AMC) for reduced operational costs.

The growing network of high-performing STPs from leading manufacturers like Netsol Water, EnviroTech, Biogreen and Ecofriends is vital in treating Gurgaon's sewage. Their collective treatment capacity, running into hundreds of millions of liters daily, prevents untreated sewage discharge into water bodies. STPs have begun transforming the city’s water and sanitation landscape. Strong execution by sewage treatment companies and strict monitoring by government agencies can help Gurgaon achieve the target of zero liquid discharge soon.

Types of Sewage Treatment Plants?

Sewage treatment removes contaminants from wastewater and household sewage to produce an environmentally safe fluid waste stream suitable for disposal or reuse. Sewage treatment plants utilize mechanical, biological and chemical processes to achieve this goal through various stages.

Based on the treatment technology used, sewage treatment plants can be categorized into:

1- Activated Sludge Process Treatment Plants

2- Trickling Filter Treatment Plants

3- Sequential Batch Reactor (SBR)

4- Membrane Bio-Reactor (MBR)

5- Moving Bed Biofilm Reactor (MBBR)

Let us understand the working of these prominent technologies:

Activated Sludge Process Treatment Plants

The activated sludge process is the most commonly used sewage treatment method globally. As sewage enters the plant, preliminary treatment uses bar screens to remove grit, debris, and heavy solids. Flow is then stabilized in equalization tanks before transferring to the aeration tank.

Here, air is injected to facilitate aerobic biological treatment by the activated sludge bacteria. The microbes break down organic pollutants, converting ammonia to nitrates. Secondary clarifiers then allow the activated sludge to settle, treating effluent up to 20mg/L BOD levels. Part of the sludge is recycled into an aeration tank, while the excess is wasted. Chlorine is finally added for disinfection before discharge/reuse. Though energy-intensive, the activated sludge process can handle large fluctuations in sewage volumes. However, maintaining optimum dissolved oxygen and flow patterns in the tank is crucial.

Trickling Filter Treatment Plants

Trickling filters use a bed of rocks, gravel, slag, peat moss, or plastic media over which sewage is distributed to allow the growth of a biological layer composed of bacteria, fungi, protozoa, etc. As the effluent trickles over the filter media, these microorganisms break down and oxidize the organic pollutants. Trickling filters can efficiently treat abiotic sewage but have limitations in breaking down nitrogen components. They occupy less space than the activated sludge process but produce a high volume of sludge washout in case of fluctuating flows. Maintenance costs are lower, however, and the process is more stable due to the attached microbial growth.

Sequential Batch Reactor (SBR)

The SBR works on activating the sludge process in batches rather than continuous flow. Equalization, aeration and clarification are achieved in a timed sequence in the same reactor tank. Raw influent enters an empty tank; aerobic treatment happens for several hours before the mixed liquor is allowed to settle. Treated supernatant is then decanted, and a part of the sludge is wasted at the end of the batch. The cyclic operation makes the SBR suitable for areas having considerable sewage variation since the batch sizes can be easily adjusted. Automated control systems allow flexibility in operation. However, the batch process requires accurate level sensors and controls to sequence the cycles properly.

Membrane Bio-Reactor (MBR)

The MBR combines suspended growth biological treatment with membrane filtration, like microfiltration/ultrafiltration. In the aeration tank, membranes are submerged alongside the permeate, which is drawn through suction. This produces a high-quality effluent free from suspended solids suitable for reuse applications.

Though capital costs are higher, MBR plants occupy much less space. Separate clarification and tertiary treatment are avoided, given the membrane barrier. It can handle fluctuating organic and hydraulic loads better, provided membrane capacity is sufficient. However, membrane cleaning and replacement are required periodically.

Moving Bed Biofilm Reactor (MBBR)

In MBBR systems, the microbial biomass responsible for treatment grows on small plastic carriers kept in motion in the reactor tank through aeration. This enables the development of thicker biofilms and elevated biomass concentration to treat higher loads. The moving carriers provide abrasive action for the sloughing of excess biofilm.

MBBRs can treat high hydraulic and organic shock loads compared to conventional treatment methods. It requires less reactor volume and footprint, significantly saving construction costs. However, carriers may accumulate over time and require replacement. The process also needs additional solids separation.

Various ingenious biological and mechanical sewage treatment technologies have now emerged to handle growing volumes and types of sewage. The choice depends on influent organic/hydraulic loading patterns, discharge norms, land and capital availability. With customized design and execution, modern STPs can now ensure towns and cities sustainably reclaim vital water resources.

What is the cost of STP maintenance?

Sewage treatment is vital for cities and towns to prevent contamination of water bodies by uncontrolled wastewater discharge. While significant investments are made to install advanced sewage treatment plants (STPs), insufficient maintenance can undermine functioning and lead to process upsets over time. Proper maintenance is, therefore, necessary to keep STPs running at design performance levels.

Major Cost Components

The significant expenses involved in STP maintenance include:

1- Power – For running pumps, aerators, decanters, agitators etc. Generally, it comprises 40-60% of total operating costs, depending on the technology.

2- Consumables – include chemicals like alum, polymer, and chlorine, filter media and mechanical parts, which require periodic replacement.

3- Manpower – Staffing is required for process supervision, daily testing, desludging, repairs, etc. Can account for 15-30% of O&M costs.

4- Maintenance Services – Adhoc costs for breakdown repairs, preventive upkeep, instrumentation calibrations, etc, which ensure optimal STP performance.

5- Disposal Charges – For removal by authorized agencies periodically as per local bylaws.

6- AMC Charges – Annual maintenance cost for specialized upkeep by STP OEM to ensure consistent plant performance.

Power Usage Optimization

Power consumption in STPs depends on influent load, equipment installed, automation level and associated usage pattern. Advanced technologies like MBBR and MBR consume much less energy than conventional ASP.

Steps for reducing power usage include:

1- Installing variable frequency drives for aerators that match airflow to real-time requirements.

2- Minimizing pumping requirements by planned layout and gravity flow systems wherever possible.

3- Automated controls with dissolved oxygen sensors for aeration on demand rather than continuous.

4- Ensuring peak loading conditions are spread out evenly to reduce system start-stop cycles.

5- Maintaining transformers, cables and switchgear for maximum efficiency through preventive upkeep.

Consumables Cost Reduction

While certain media/consumables like alum, chlorine and microfilter cartridges have predictable replacement timelines, others may vary greatly depending on influent quality and operating conditions. Steps for lowering consumables costs include:

1- Optimum process control to minimize unnecessary chemical dosing.

2- Applying automatic coagulant/chlorine dose optimizing systems based on feedback for controlled addition.

3- Using volume purchase contracts from vendors to avail the best rates on bulk orders.

4- Exploring alternative media with longer life but similar performance.

Plant Automation

Automating STP functions enhances consistency and minimizes dependence on skilled manpower. Installing automated sludge removal systems and remote telemetry systems to track plant health can significantly reduce operational costs.

AMC Benefits

Entering annual maintenance contracts with STP manufacturers helps accurately budget for specialized maintenance costs annually. The AMC charges offset expenses related to breakdown repairs, yearly audits, media refills, instrumentation calibrations, and membrane/filter replacements using guaranteed response timelines. AMC services enhance STP infrastructure reliability.

Budgeting adequately for the cost components outlined above is necessary for STPs to achieve consistent treatment quality and full lifecycle. Technology enhancements, process automation and contractual services can help significantly rationalize overall maintenance costs.

What is the Treated water limit for STP as per HPPCB (Haryana Pollution Control Board)?

Haryana State Pollution Control Board (HSPCB) monitors all industrial and sewage discharges to prevent water, air and soil pollution in the state. They have stipulated stringent quality standards for treated sewage discharged from in-house Sewage Treatment Plants (STP) of residential colonies, commercial complexes and industries in Haryana.

Biochemical Oxygen Demand (BOD)

BOD indicates the amount of organic matter present in the sewage. High BOD leads to faster depletion of oxygen in receiving water bodies, causing a threat to aquatic life.

Standards:

For Metropolitan Cities - Less than 10 mg/l

For All Other Cities - Less than 20 mg/l

Chemical Oxygen Demand (COD)

COD measures the quantity of organic pollutants found in sewage. High COD can cause environmental stress in the ecosystem.

Less than 50 mg/l for discharge into public sewers

Less than 250 mg/l for discharge into water bodies or for land application.

Total Suspended Solids (TSS)

TSS refers to microscopic organic and inorganic solid matter suspended in the wastewater, which must be reduced before discharge.

Less than 10 mg/l for discharge into public sewers.

Less than 100 mg/l for discharge into surface water bodies.

pH Value

It indicates whether the discharge is acidic, alkaline or neutral. Extreme pH conditions severely affect biological treatment and aquatic life.

Between 5.5 to 9.0

Total Nitrogen

Presence of excessive nutrients like nitrogen & phosphorous leads to eutrophication.

Less than 10 mg/l (for discharge into lakes & ponds)

Total Phosphorous

Less than 1 mg/l for discharge into ponds and lakes

Less than 5 mg/l for discharge into streams & public sewers

Fecal Coliform

Pathogens like fecal coliform can negatively impact human health through waterborne diseases.

Less than 1000 Most Probable Number per 100 millilitre sample

Oil & Grease Must be absent in the treated sewage as per visual examination.

HSPCB mandates that sewage be treated to strict quality benchmarks before discharging into a public sewage network or any inland water body. Failing to meet these charges attracts legal action.

Advanced Treatment Solutions Emerging

Most sewage treatment plants in Haryana employ conventional activated sludge processes or secondary biological treatment methods. But with the latest revision in norms making them more stringent, these technologies may find it hard to consistently meet all parameters like total nitrogen, phosphorous and bacteria removal.

Hence, advanced tertiary treatment methods are now gaining prominence. These use membranes, oxidation or disinfection processes as additional treatment stages after secondary treatment.

Ultrafiltration (UF) and Reverse Osmosis (RO) membranes produce a particulate, bacteria and virus-free high-purity effluent. RO-treated sewage can be safely reused for non-potable applications like gardening, toilet flushing and process cooling. Ozonation and chlorine dioxide dosing can disinfect resistant microbes.

Wetlands Act as Polishing Units

Constructed wetlands with mineral-rich substrates and aquatic plants are also becoming popular as a tertiary polishing stage. They allow additional pathogen removal through natural sedimentation, filtration, uptake and predation dynamics. Being rich ecosystems, wetlands also attract local biodiversity.

Such integrative advanced treatment trains can help STPs in Haryana reliably meet the progressively tightening treated sewage standards. Adopting modular approaches allows scaling capacity as townships expand. Proactively adopting these technologies and regular plant audits are key to long-term compliance.

How Netsol Water is marked as the dominant Sewage treatment plant manufacturer in Gurgaon?

Gurgaon’s rapid urbanization over the last two decades led to enormous strains on its infrastructure and water systems. Lack of sewage treatment capacity resulted in untreated discharge and contamination of water bodies. This necessitated the intervention of efficient STP manufacturers and operators like Netsol Water to mitigate the crisis through technical expertise and execution excellence.

We discuss below how Netsol leveraged a customer-centric approach, advanced technologies, robust service infrastructure and process innovations to become Gurgaon’s top STP company, successfully handling millions of liters of sewage daily across diverse projects.

Customer-Centric Approach

Netsol follows a consultative approach right from the design phase through execution and O&M. Detailed discussions are held with the client’s facility teams to assess daily sewage output parameters, space constraints, layout considerations, expansion plans, etc. This helps provide customized STP infrastructure rather than a one-size-fits-all solution.

Technology selection, whether SBR, MBBR, conventional ASP or hybrid models, is done based on client-specific needs. Components are chosen to maximize reliability and optimize power consumption based on 24x7 usage. This tailor-made approach across 100+ STP installations has been pivotal to Netsol’s success.

Advanced Treatment Solutions

Netsol offers technically advanced decentralized and modular STP systems based on proprietary engineered designs. These ensure consistent treated sewage quality through automated operation aided by PLC-SCADA controls.

Critical parameters like dissolved oxygen are monitored in real-time to control aeration cycles and minimize power consumption. Customized biological media with a large surface area helps reliably achieve stringent pollution board norms for BOD and COD. Additional tertiary treatment technologies can be integrated into water recycling applications.

Robust After-Sales Service

Netsol recognized that timely after-sales support is crucial for STP infrastructure to cope with sudden sewage quality/quantity changes. Hence, Netsolpositioned a service team exclusively for the Gurgaon region with a ready inventory of parts like media, membranes, pumps, etc.

Resident engineers and technicians are equipped to attend urgent callouts via well-stocked service vehicles. Corrective and preventive maintenance activities ensure each installation meets operational KPIs throughout its lifecycle. This infrastructure backing has enabled performance guarantees offered to clients.

Innovation in Core Competencies

Rather than growing its scale alone, Netsol has focused passionately on strengthening its design capabilities, automation technologies, and O&M best practices. In-house teams continually identify, pilot and deploy improvements across installed STPs.

Notable examples include integrated IoT-based remote monitoring solutions, robotic sludge removal systems and automated metering of STP electricity usage. Such innovations have tangibly enhanced plant uptime, lowered operating costs and improved overall sustainability.

Industry Recognition

Owing to such well-rounded execution, Netsol has received appreciation from industry bodies. Certifications include ISO 9001 and OHSAS 18001 for quality management and occupational health/safety practices.

These endorsements showcase the operational excellence, delivery track record and support benchmarks set by the company for decentralized sewage infrastructure projects since 2005.

Major Clients Serviced

Netsol’s installations treat over 50 million liters across 4000+ complexes daily in the NCR region alone. This includes prominent townships' developed infrastructure. Commercial complexes with operational Netsol STPs. Technology parks and educational institutes have partnered with Netsol for their sewage and effluent requirements.

The Future

Having consolidated its leadership position in the Gurgaon market through best-in-class decentralized sewage treatment infrastructure and operational skills, Netsol is now expanding across Tier 1 cities like Chennai, Hyderabad and Pune. The focus remains on helping corporates and housing societies recycle millions of liters daily leveraging energy-efficient and automated treatment solutions.

With urbanization accelerating, opportunities for reliable decentralized sewage treatment partners shall tremendously increase. As a dominant industry player, Netsol is poised to lead in shaping India’s water sustainability journey through continued innovation.