How to design an Activated Carbon Filter?

This term refers to incomplete combustion of fossil. Imagine a piece of burnt wood left after a campfire. Only the combustibles of wood burned out due to either inadequate heat or inadequate oxygen supply. Most of the remaining black charcoal is carbon. The industrial process of making charcoal does this by heating the material in a vacuum chamber that releases all volatile compounds and leaves all carbon. Charcoal is widely used for burning but coconut shells are also used. Each substance makes a slightly different type of charcoal.

How is coal activated?

Activated carbon is carbon that has undergone additional treatment to better trap gas molecules. First, hot air, carbon dioxide, or steam is injected, creating a grid of small pores in the carbon, which significantly increases the surface area. This greatly increases the number of places where molecules are trapped, making charcoal much more effective as a filter medium.

During World War I, gas masks used charcoal air filters to remove some of the deadly gases used against the army, but they are only effective against some toxins.

How do carbon air filters trap gaseous pollutants?

Activated carbon air filters remove pollutants byadsorption. Note that this is different from absorption. During absorption, substances that are removed (such as water) are absorbed by the structure of the absorbent (such as sponge) but are not part of the absorbent at the molecular level. Therefore, when the sponge absorbs water, the water is not chemically bound to the sponge.

The carbon filter, on the other hand, uses adsorption rather than absorption. The main difference is that contaminants adhere to the outside of the coal during adsorption. On the other hand, in the case of absorption, contaminants are absorbed by the structure itself like a sponge.

Carbon is a lattice of carbon atoms bonded to each other. The activation process is very important because increasing the surface area increases the area to which the gas adheres. When molecules of gaseous material pass through carbon, if there are open adsorption sites, they can adhere to the surface of the bed.

Effective use of activated carbon air filter Carbon air filters is an important part of household air purification systems, but they need to be used properly.

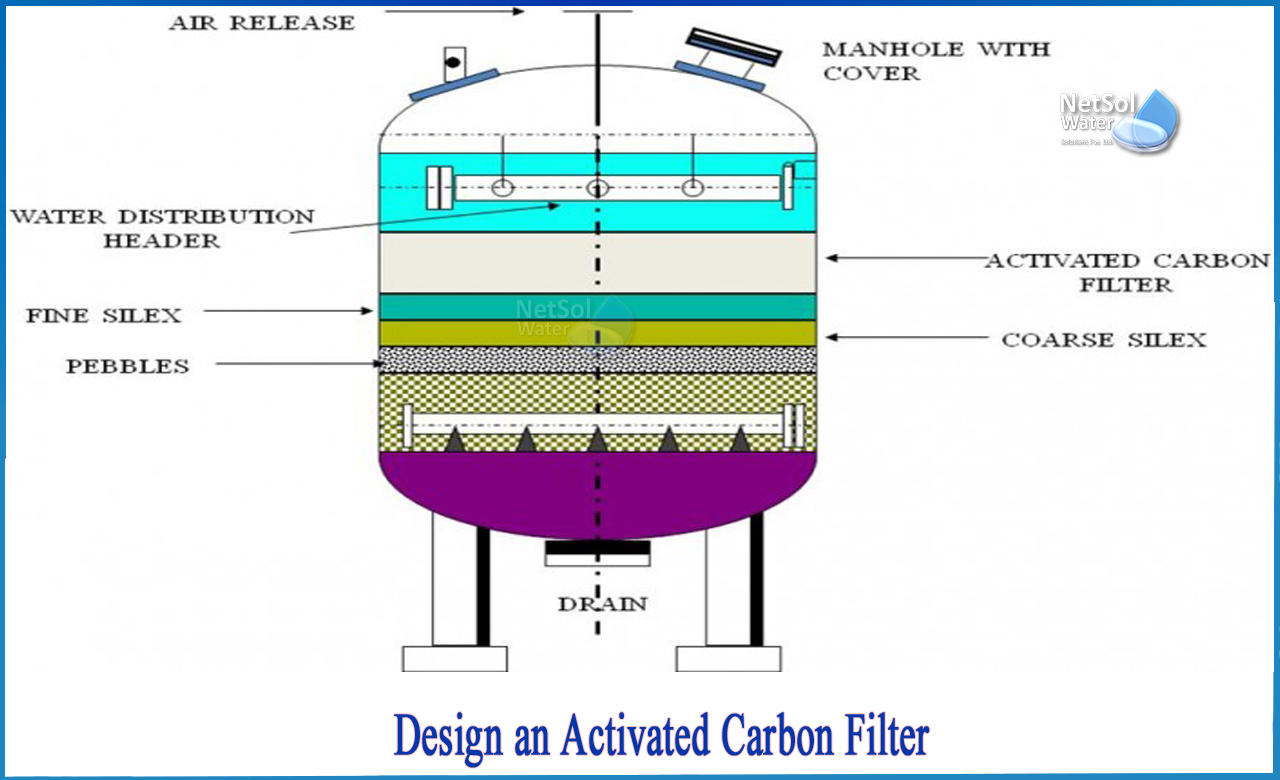

Design of Carbon Filter:

In designing the size of GAC(granular activated Carbon) columns, the following factors are taken into consideration:

1. Empty-bed contact time (EBCT),

2. Hydraulic loading rate,

3. Carbon depth,

4. Number of contactors.

GAC filters may be designed as up or downflow systems consisting of one or more vessels in series or in parallel.

Let us understand this in a simple manner:

QUESTION: If the influent is 12 m3/ hour, using a mesh size of 8*30 m, design an activated carbon filter. Use recommended values and in case of missing data, assume suitable data.

ANSWER:

a. For 8x30 mesh size and 2 gpm/ft3 flow rate.

Log CI/ CE= B/ V

=Log 1/ 0.001 = B / 2 gpm

pH= 7 of water, T = 21°C & a break point = 0.01 of Cl2 as given by IS table

Then,B = 4 for 8x30 mesh size.

b. Applying equation again for the actual design flow rate =12 m3/ hour = 44 gpm,

Influent concentration= 1ppm Cl2,

Effluent = 0.1ppm Cl2

Log 1/0.10 = 4 /V

V = 4 GPM/ft3

c. Bed volume= 44 gpm /4 gpm/ ft

= 10 ft. for8*30 mesh size

d. Using bed as filtration adsorption from IS code, flow rate £ 2.5 gpm I ft2

(A-1) mesh size 8x30

Applying equation,

Log CI/ CE=(B * bed height) /(superficial flowrate gpm/ft2)

Therefore, bed height L = 0.625 ft,

D = 4.6 feet

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.