What is High Rate Activated Sludge BIOFOR Technology?

Biological Filtration and Oxygenated Reactor or BIOFOR is utilized in secondary and tertiary treatment. The method is typically utilized to remove BOD, TSS, and ammonia pollutants. Because of the filtering activity of the filter medium, these units discharge treated water that meets high quality criteria for all parameters.

These units can handle higher filtration velocities because they are designed to manage heavier organic loadings than traditional systems. The devices combine soluble pollutant treatment and solids separation in a single compact reactor, eliminating the need for secondary clarifiers. The filter operation is automated via a PLC-based control systems.

What is the working operation in BIOFOR Systems?

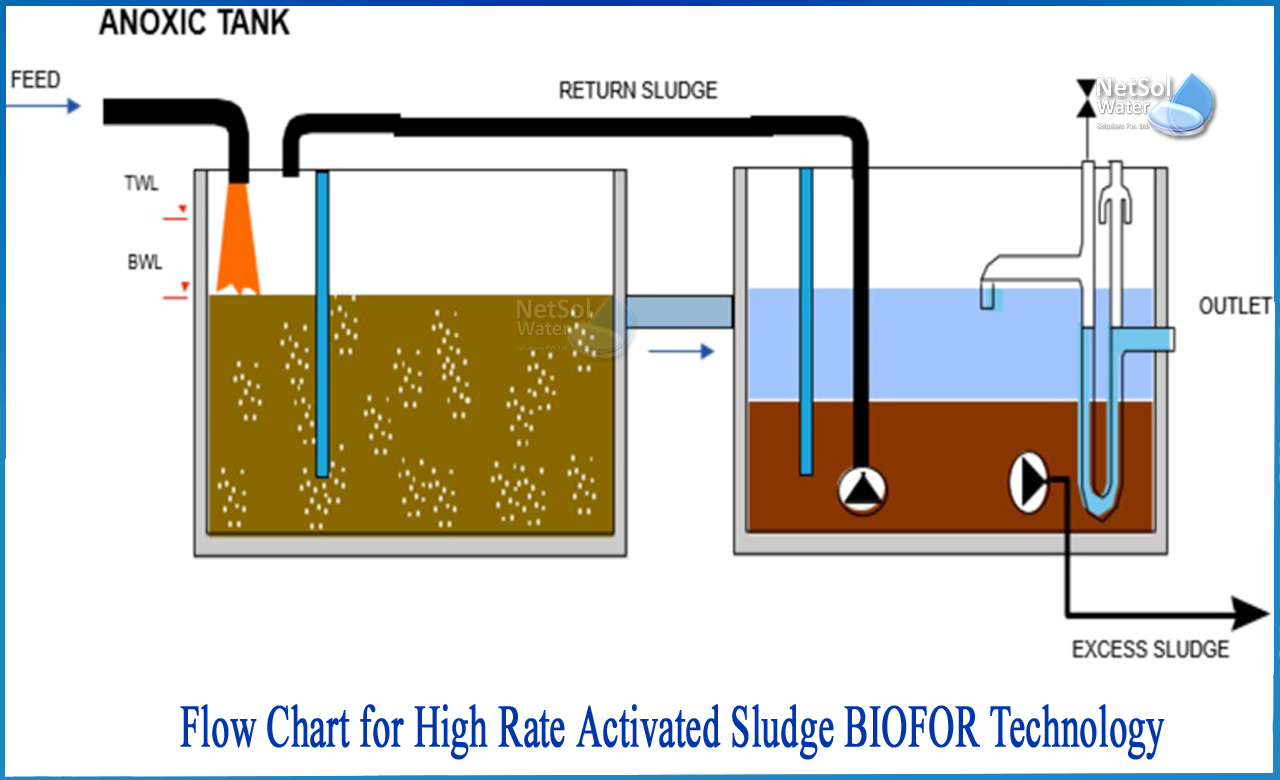

The effluent to be treated enters constantly from the bottom of the reactor, and the nozzle underdrain distributes it evenly throughout the entire filter surface area. After that, the water is filtered using filter medium, which traps the suspended particles. The high concentration of fixed-film biomass that is kept on the filter media during the filtration cycle eliminates carbonaceous and nitrogenous pollutants.

Air diffusers continuously feed air into the lowest section of the reactor in the aerated variants for BOD removal and nitrification.Because the treated water is at the surface of the filter (in contact with the atmosphere) and the untreated water enters at the bottom, the adoption of a co-current upflow design helps to prevent odour formation. The number of filters in the filtration service is determined by the amount of water that enters the facility.

Key features of the High Rate Activated Sludge BIOFOR-F Technology

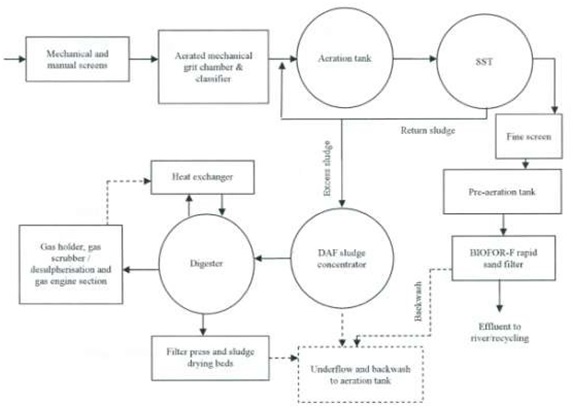

1: The primary sedimentation tank is not included in the flow scheme;

2: A high level of mechanization and sophistication is required;

3: Aerated grit chamber and classifiers are of superior quality;

4: Aeration in the second stage and quick sand filtering by using biologically active filter media;

5: Tapered air diffusion system with circular aeration tank;

6: Sludge thickening with dissolved air flotation;

7: Temperature-controlled anaerobic sludge digestion and digester heating.

8: Biogas is used to mix the contents of the digester.

Advantages of the High Rate Activated Sludge BIOFOR-F Technology

A) Due to high-speed processes, the layout is compact;

B) Aeration efficiency is improved by using a diffused and tapered aeration system;

C) Space savings due to the removal of primary sedimentation;

D) Adherence to tougher discharge regulations;

E) Industrial effluent appropriate for high-end applications;

F) Consistent digester performance and gas production;

G) Almost self-sufficient in terms of energy requirements;

H) There are no aerosols or odours in the working space.

The Process flow diagram (PFD) of High Rate Activated Sludge BIOFOR-F Technology

Applications of BIOFOR Technology

1: BIOFOR for the removal of BOD, COD, and TSS;

2: BIOFOR for ammonia nitrogen nitrification;

3: BIOFOR for BOD elimination and nitrification at the same time;

4: BIOFOR for nitrate elimination without extra carbon source as a pre-denitrification phase;

5: BIOFOR for nitrate elimination as a final denitrification stage with carbon addition;

If you want to know more about High-Rate Activated Sludge BIOFOR Technology, then youcan have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.