What are FlocClays?

FlocClays are powdered flocculants based on bentonite and organoclay that remove oils, grease, surfactants, dyes, inks, coolants, solvents, metals and heavy metals, and suspended solids from wastewater. FlocClays are made up of bentonite, organoclay, and other basic ingredients that cause oil and grease encapsulation, removal of other organics via partition and chemical bonding, and removal of heavy metals via precipitation, ion exchange, and chemical bonding.

To break oily emulsions, precipitate heavy metals, coagulate, flocculate, and condition sludge, typical treatment methods necessitate the addition of various chemicals. Several steps are usually required, necessitating the use of multiple mixing tanks and additional equipment.

It is not unusual for this process to take several hours to complete these objectives. FlocClay causes contaminants to flocculate in minutes rather than hours. The entire treatment process can be completed using the FlocClay one step method by adding a small amount of FlocClay directly to the wastewater stream.

FlocClay for waste water

FlocClay powder flocculants are useful for treating wastewater streams with a monthly volume of 50,000 gallons or less. They can remove oils, other organics, and heavy metals all at once, eliminating the need for pre-treatment with acids and salts.

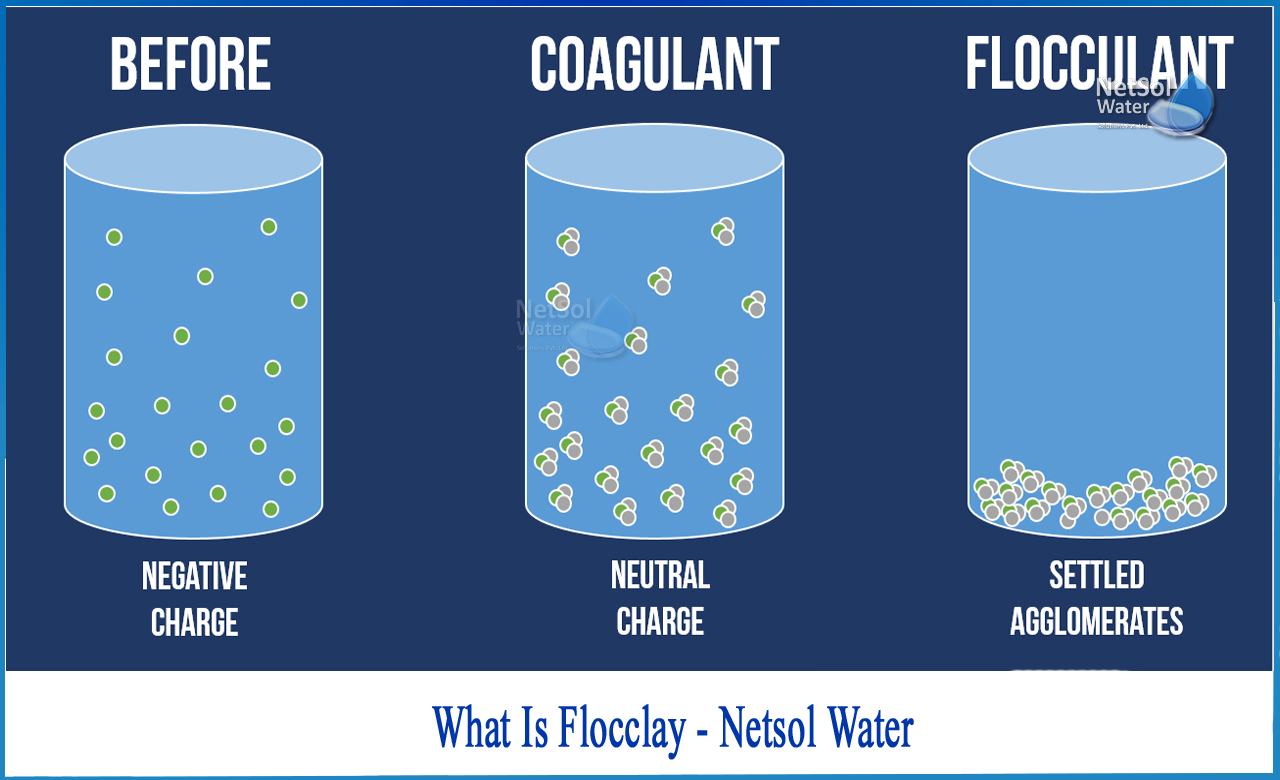

Coagulation and flocculation are important processes in water treatment, with coagulation aimed at destabilizing and aggregating particles via chemical interactions between the coagulant and colloids, and flocculation aimed at sedimenting the destabilized particles via aggregation into floc.

Applications of FlocClay

1: Chemistry of the surface

The process of causing fine particulates to clump together into a floc is referred to as flocculation in colloid chemistry. The floc may then float to the surface of the liquid (creaming), settle to the bottom (sedimentation), or be easily filtered from the liquid. The flocculation behavior of soil colloids is closely related to the quality of freshwater.The high dispersibility of soil colloids not only causes turbidity in the surrounding water, but it also causes eutrophication due to nutrient adsorption in rivers, lakes, and even boats submerged in the sea.

2: Chemistry of matter

In the case of emulsions, flocculation refers to the grouping of individual dispersed droplets so that the individual droplets retain their identity. Flocculation is thus the first step in the emulsion's further ageing (droplet coalescence and the ultimate separation of the phases). Flocculation is commonly used in mineral dressing, but it can also be used to design the physical properties of food and pharmaceutical products.

3: Civil engineering

In civil engineering and earth sciences, flocculation is a condition in which clays, polymers, or other small charged particles attach and form a fragile structure known as a floc. When mechanical agitation is removed from dispersed clay slurries, the dispersed clay platelets spontaneously form flocs due to attractions between negative face charges and positive edge charges.

4: Biology

Flocculation, in conjunction with microfiltration, is used in biotechnology applications to improve the efficiency of biological feeds. The addition of synthetic flocculants to the bioreactor can increase the average particle size, allowing for more efficient microfiltration. Cakes form and accumulate when flocculants are not added, resulting in low cell viability. Because the cells are generally negatively charged, positively charged flocculants perform better than negatively charged flocculants.

Specific benefits and drawbacks

· Coagulation/flocculation can remove specific pollutants from wastewater that would otherwise be impossible to remove without the addition of these chemicals.

· These tanks and dosage units require only a small investment. However, one significant disadvantage of this technique is the high operational costs. In some cases, large amounts of coagulant and flocculant are required to achieve the desired level of flocculation. A certain amount of physicochemical sludge is also produced, which is typically processed externally. These costs can quickly add up, especially when dealing with large amounts of wastewater.

The correct chemical dosage is also critical for the process to function properly. This is more difficult with wastewater that has a wide range of composition. In this case, effective wastewater buffering is a good solution.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.