What is ETP in dairy industry?

Due to the high-water consumption, the dairy industry is one of the most polluting of the food industries. Dairy is one of the major sources of water pollution. Given the increased milk demand, India's dairy industry is expected to expand rapidly, with waste generation and related environmental issues becoming increasingly important. When discharged to the surface land or water, poorly treated wastewater with high levels of pollutants caused by poor design, operation, or treatment systems causes major environmental problems.

Waste water from dairy industry:

Dairy waste water contains highly putrescible organic constituents. This necessitates prompt and adequate waste water treatment before disposal to the environment. Almost all of the organic components of dairy waste are biodegradable. As a result, the wastewater can be treated biologically, either aerobically or anaerobically. These wastes are considered potential pollutants when they have a negative impact on the environment and are typically released in the form of solids, liquid effluents, and slurries containing a variety of organic and inorganic chemicals.

Effluent treatment:

Effluent treatment in industries to meet discharge standards has always been a major issue for industrialists. Every industry effluent treatment plant must treat effluent for this purpose in their own industry through effluent treatment plants. Before discharging treated effluent onto land or into any surface water body, industries must comply with the effluent discharge standard norms. Characterization of waste water, treatability studies, and planning of proper units and processes for effluent treatment are all required for proper processes in the ETP.

While the industry manufactures milk, butter, or cheese through processes such as pasteurisation or homogenization, high levels of BOD (Biochemical oxygen demand) and COD (Chemical oxygen demand) are produced, which must be treated before being discharged into the environment. Other common effluents include suspended solids, milk fat, and dairy odours that must be addressed.

Every dairy production unit requires a Dairy Wastewater Treatment Plant that efficiently addresses unbalanced levels of BOD, COD, suspended and dissolved solids, resulting in safe industrial waste disposal.

Operation of dairy industry with effluent treatment:

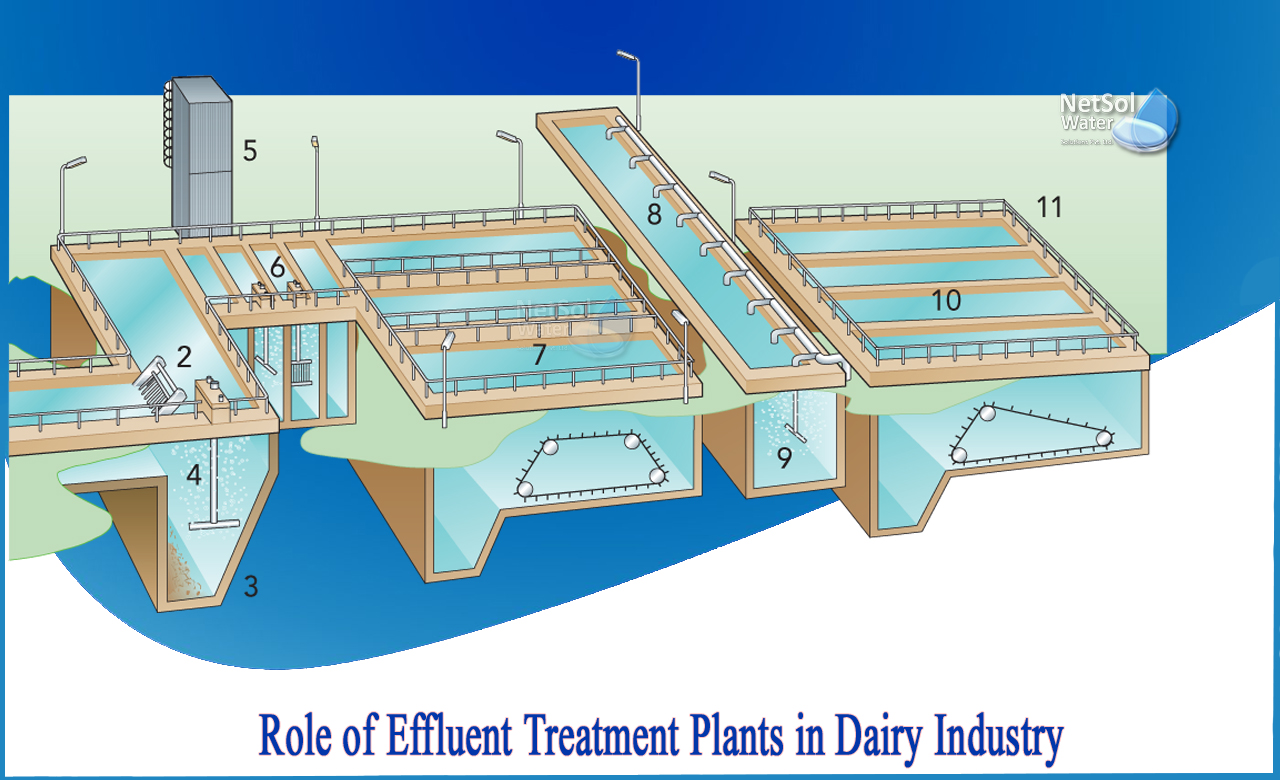

The dairy effluent treatment plant follows a set of steps:

· The pH is first adjusted to 8.5 using pH controllers such as caustic or acid. Any emulsions are then broken down and solids precipitate with the help of a de-emulsifier.

· Other important steps in the treatment of dairy effluent include flocculation and dissolved air flotation. The wastewater is flocculated by passing it through a slow mix zone, where the particles are gathered together to form larger ones, which are then treated further using the air flotation technique.

· The dissolved air flotation technique works as follows: air flotation system bubbles are propelled by a Recycle Air Dissolving system, which blows the treated effluent, pressurises it, and dissolves it with air.

· Finally, the sludge batch is pumped through the filter press and disposed of in accordance with environmental regulations.

Finally, the Effluent Treatment System designed specifically for the dairy industry results in efficient resource use, lower operating costs, smooth dairy functions, compliance with environmental regulations, and peace of mind.

Conclusion:

Unlike many other industries, the dairy industry is at the top of the list in terms of industrial waste production. The dairy industry process reveals that approximately 2 litres of water are used to process 1 litre of milk. This clearly shows the massive scale of effluents that must be treated in order to improve operations and comply with environmental regulations.

Netsol water India's leading manufacturer of all water treatment plants. Our environmental services include the concept of commissioning Wastewater Treatment Plants for industries as well as Sewage Treatment Plants.