How to Achieve Zero Liquid Discharge in Effluent Treatment Plants?

Industries experience increasing demands for effective wastewater management. Zero liquid discharge in ETP (Effluent Treatment Plant) systems provides sustainable solutions that help industries handle wastewater. This approach changes traditional wastewater treatment into a closed-loop system where facilities prevent liquid waste from leaving their premises. Industries need this solution since water scarcity impacts numerous regions across the globe. Environmental regulations create new standards. Industries must discover improved methods to treat industrial effluents. Zero liquid discharge enables organizations to extract valuable resources from wastewater while safeguarding the environment. This technology empowers industries to reuse water throughout their processes which decreases fresh water usage. The advantages go beyond protecting the environment. Organizations that integrate zero liquid discharge systems experience long-term financial benefits through water reuse and resource recovery.

We will discuss the essential elements of achieving zero liquid discharge in ETP plants including technologies, methods and best practices.

Zero Liquid Discharge Systems

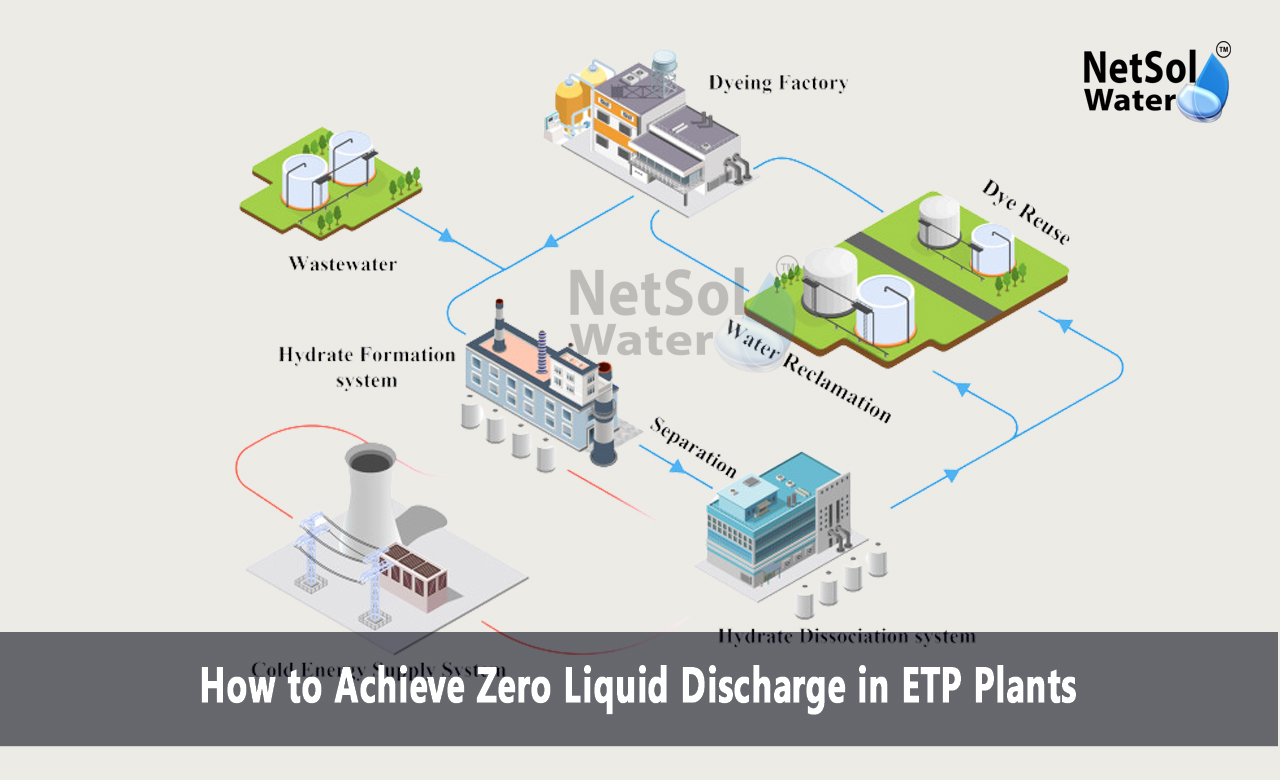

Zero liquid discharge begins with understanding system operations in ETP plants. A zero-liquid discharge system transforms wastewater through multiple stages until it converts all liquid into solid waste or clean water. This process demands careful planning and execution. The system design integrates many factors, including industry-type wastewater composition and treatment objectives. Modern zero liquid discharge systems employ advanced technologies that enhance process efficiency compared to traditional methods. These systems enable industries to fulfill environmental requirements while optimizing water recovery. The technology advances continuously making zero liquid discharge available to various industries. Let us have a look at some key aspects of zero liquid discharge systems.

System Components

A complete zero liquid discharge system incorporates multiple treatment units that function together.

· The pretreatment stage eliminates large particles and balances pH levels.

· Membrane filtration systems then separate dissolved solids from water.

· Evaporation and crystallization units process concentrated waste streams.

These components operate in sequence to maximize water recovery.

Process Control

Effective operation demands exact control of multiple parameters. Operators must monitor temperature pressure and flow rates continuously. Automated systems maintain ideal conditions throughout the process. Regular maintenance ensures component efficiency.

Resource Recovery

Modern systems extract valuable materials from wastewater streams. Industries can obtain metals, salts, and other compounds. This recovery decreases the system's operational expenses. The extracted materials often generate commercial value.

Technologies for Zero Liquid Discharge

Zero liquid discharge in ETP plants succeeds through appropriate technology selection. Each technology fulfils specific roles in the treatment chain. These technologies collaborate to achieve complete water recovery. The field progresses as new innovations enhance system efficiency. Let us have a look at some essential technologies in zero liquid discharge systems.

Membrane Systems:

· Advanced membrane technologies initiate the treatment process.

· Reverse osmosis eliminates dissolved solids from wastewater.

· Ultrafiltration captures smaller particles and organic matter.

· Nanofiltration targets specific ions and compounds.

Thermal Systems

Thermal processing handles concentrated waste streams. Multiple effect evaporators concentrate the wastewater further. Crystallizers extract solid waste from concentrated solutions. These systems incorporate energy-efficient designs to minimize operational expenses.

Hybrid Solutions

Combined approaches generate improved results. Some systems integrate membrane and thermal technologies. This combination optimizes energy consumption and treatment efficiency. Hybrid systems adapt effectively to changing wastewater conditions.

Implementation and Operation

Zero liquid discharge in ETP plants demands thorough planning and execution. Implementation progresses through several stages, from design to startup. Proper operation ensures optimal system performance. Industries must educate their staff about these advanced systems. Let us have a look at some important aspects of implementation and operation.

System Design: Each facility requires customized designs based on specific requirements. Designers consider wastewater characteristics and treatment goals. Planning includes space requirements and utility connections. Designs incorporate future expansion possibilities.

Operational Parameters: Successful operation depends on proper condition maintenance. Operators adjust chemical dosing to match wastewater characteristics. Flow rates change based on system performance. Continuous monitoring prevents operational issues.

Maintenance Schedule: Regular maintenance ensures smooth system operation. Staff inspect and clean equipment periodically. Facilities stock replacement parts for immediate repairs. Effective maintenance extends system life and maintains efficiency.

Conclusion

Zero liquid discharge in ETP plants marks significant progress toward sustainable industrial operations. This technology delivers complete wastewater management solutions while protecting the environment. Industries planning to implement these systems should connect with experienced professionals who understand specific industrial requirements.

Transform your wastewater management system today. Our team of experts stands ready to discuss how zero-liquid discharge benefits your facility. We provide personalized consultations to identify the right solution for your industry.

Contact Netsol Water at:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com