Sewage Water Problem In Delhi

Delhi is the capital city of India. The diversity of the population in Delhi is influenced by the extensive opportunities for career development, the flourishing tourism industry, and various factors contributing to diversification. The sewage water problem in Delhi is a multifaceted challenge that demands immediate attention and collaborative efforts with a combination of improved infrastructure, stringent regulations, public awareness campaigns, and proactive government policies.

Role of Sewage Treatment Plant Manufacturer in Delhi NCR

Sewage Treatment Plant manufacturer in Delhi NCR have an important role in solving the problem of water and wastewater treatment. It is because the NGO and DDA have limited resources as compared to the demands of clean water whereas the best sewage treatment plant manufacturer in Delhi Like Netsol Water has a sophisticated water treatment STP plant that is capable of treating extensive levels of water demands, along with this these local Authorities can collaborate with such companies to fulfill the demands of water.

How much sewage and Effluent is generated in Delhi daily?

India's capital, Delhi, is having a terrible time controlling the enormous waste that its expanding population produces. Based on the available data, Delhi's citizens generate more than 792 million gallons of wastewater daily (MGD). This enormous volume of wastewater poses a significant risk to the environment and public health if improperly handled.

Now, the estimated population of Delhi is more than 35 million. The ability to dispose of and treat; however, the sewage treatment capacity in Delhi is estimated to be around 600 MGD. This means that over 100 MGD of untreated sewage is discharged directly into the Yamuna River or other water bodies. This poses severe risks of water pollution and the spread of water-borne diseases. Managing this massive amount of sewage generation and ensuring treatment before disposal is a crucial challenge facing Delhi.

Delhi generates a massive amount of sewage each day - This is equivalent to 3,000 Olympic-sized swimming pools of raw sewage produced daily in the capital!

Out of the 792 MGD of sewage generated, Delhi can treat only 632 MGD in its 35 sewage treatment plants (STPs). This leaves a gap of 160 MGD, meaning over 20% of the sewage goes untreated. Additionally, actual treatment levels are even lower. Delhi Jal Board data shows that only 547 MGD are being treated daily due to operational issues at STPs.

Most STPs do not meet the prescribed standards. 62% of the operational STPs in Delhi do not conform to the regulatory standards for sewage treatment set by the Central Pollution Control Board (CPCB). To make matters worse, much of the partially treated sewage from faulty STPs is discharged directly into the Yamuna River instead of being recycled for non-potable applications. This severely pollutes the river, which is already 'unfit' for bathing, let alone drinking. The city's water supply depends on the Yamuna for over 70% of its share.

Long story short, Delhi can treat only around 47% of the sewage it generates today.

How many Sewage Treatment Plants are there in Delhi and What is the main problem with Sewage Water in Delhi?

Delhi generates around 792 million gallons per day (MGD) of sewage from its bustling population of over 30 million. However, the city has only 35 sewage treatment plants (STPs) with a total treatment capacity of 632 MGD, leaving a gap of 160 MGD.

To make matters worse, 22 of these 35 STPs do not meet the prescribed regulatory standards set by the Central Pollution Control Board (CPCB) for parameters like Total Suspended Solids (TSS), Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD). Even some newly built STPs are found non-compliant.

Why Sewage Treatment Plants and Effluent Treatment Plants are required in Delhi?

STPs and ETPs are essential for Delhi to manage its vast volumes of wastewater in an environmentally sustainable manner. They safeguard public health, conserve water resources and support the city's expanding infrastructure needs. Sewage treatment plants (STPs) and effluent treatment plants (ETPs) are critical for Delhi for the following reasons:

To prevent pollution of water bodies:

1- Avoid the spread of diseases

2- Meet environmental regulations

3- Protect limited freshwater resources

4- Support Delhi's growing population

5- Reduce river pollution

What are the benefits of modern sewage treatment for corporates and private organizations in Delhi?

With Delhi's sewage management infrastructure bursting at its seams, more and more corporations and private organizations in the city are embracing modern in-house sewage treatment solutions. Installing advanced Sewage Treatment Plants (STPs) within one's premises provides several benefits:

1- Help meet industry effluent discharge norms: Various industries like textile, tannery, paper etc. generate significant wastewater. An in-house STP allows treatment of this effluent to meet pollution control board discharge norms before releasing into city sewers.

2- Reduce freshwater footprint: STPs enable recycling treated wastewater for non-potable uses like gardening, cooling systems, toilet flushing etc. This reduces the organization's dependence on freshwater sources.

3- Reuse treated sewage as process water: For industries like textile units, the treated effluent can directly substitute freshwater needs for various processes after meeting the quality standards. This brings significant water savings.

4- Lower sewerage charges: Organizations pay sewerage charges to the Delhi Jal Board based on the amount of wastewater discharged. An in-house STP reduces this volume, directly reducing sewerage expenses.

5- Enhance corporate image: Adopting on-site sewage management highlights the organization's commitment to water conservation and environmental sustainability. This builds goodwill and public image, which are intangible assets to the company.

6- Keep surrounding areas clean: STPs prevent the discharge of untreated sewage into neighboring areas and surface drains, controlling localized pollution and public health hazards.

What are the uses of treated sewage water after Government STPs and CETPs in Delhi?

Delhi generates nearly 800 million gallons of sewage per day. This is treated across 35 Sewage Treatment Plants (STPs) run by the Delhi Jal Board with an installed capacity of 632 MGD. However, the potential of the treated sewage water is not being fully utilized in the city. As per estimates, only around 20% of the treated sewage is being fruitfully reused in Delhi. The primary usage is for horticulture in parks, gardens and other public places. The Delhi Development Authority uses around 80-90 million liters of treated sewage per day from various STPs to irrigate 16500 hectares of green spaces across the city.

Why Industries should have their own sewage treatment plants in Delhi and How can they help to make Delhi Greener and help save water with the help of STP Plants?

With Delhi's sewage and effluent treatment infrastructure under severe strain, the responsibility is on industries to adopt responsible and sustainable wastewater management practices. Installing in-house sewage treatment plants (STPs) can enable enterprises to recycle and reuse their wastewater efficiently. Having a dedicated STP offers industries multiple advantages. It allows the treatment of industrial process effluent to meet the discharge norms set by pollution control authorities. The recycled water can then be used for cooling towers, boilers, cleaning, gardening and more. This reduces their daily freshwater demand significantly.

Adopting zero liquid discharge systems through STPs also helps industries lower their sewerage and effluent discharge charges paid to the Delhi Jal Board. With space constraints in Delhi, decentralized sewage treatment by industries is the need of the hour rather than depending solely on the city’s overloaded infrastructure. Industries using recycled water conserve enormous volumes of freshwater per day. This water can remain available in natural sources like lakes, rivers and aquifers for community use. With Delhi's water resources, especially groundwater, under strain, prudent use by industries is crucial.

Furthermore, reducing effluent discharge into neighboring water bodies through in-house treatment curbs localized pollution. This helps make Delhi cleaner and more environmentally sustainable. Many global corporates in Delhi have begun implementing responsible water management practices. As Delhi rapidly urbanizes, industries must mitigate their impact on its resources. Investing in STPs serves their business interests, too, through long-term water security and protection of the local environment. The Delhi government can provide incentives like fast-tracked approvals and subsidies on sewage treatment equipment to promote the adoption of greener technologies for comprehensive wastewater management.

Which STP Technology Corporate Buildings or Housing Society or Industries should choose to treat sewage water in Delhi and why?

Choosing the right Sewage Treatment or Effluent Treatment Technology is very important Since STP Technology should meet the guidelines by the DPCC ( Delhi Pollution Control Committee) and Central Pollution Control Board.

STP Technology should take the minimum space, should be cost-effective and less maintenance cost and sales after service.

Here are the STP Technologies names that are approved by DPCC ( Delhi Pollution Control Committee and give the desired result) -

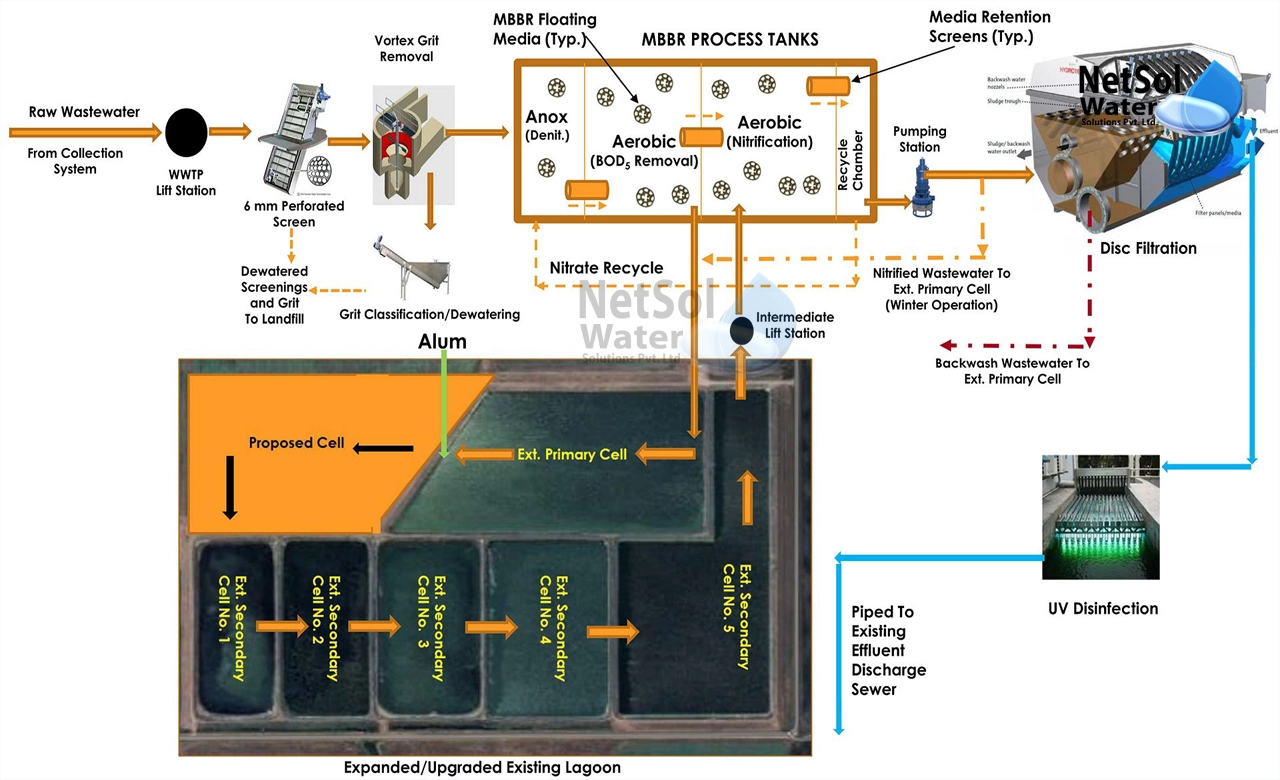

1- MBBR - Moving Bed Bio Reactor

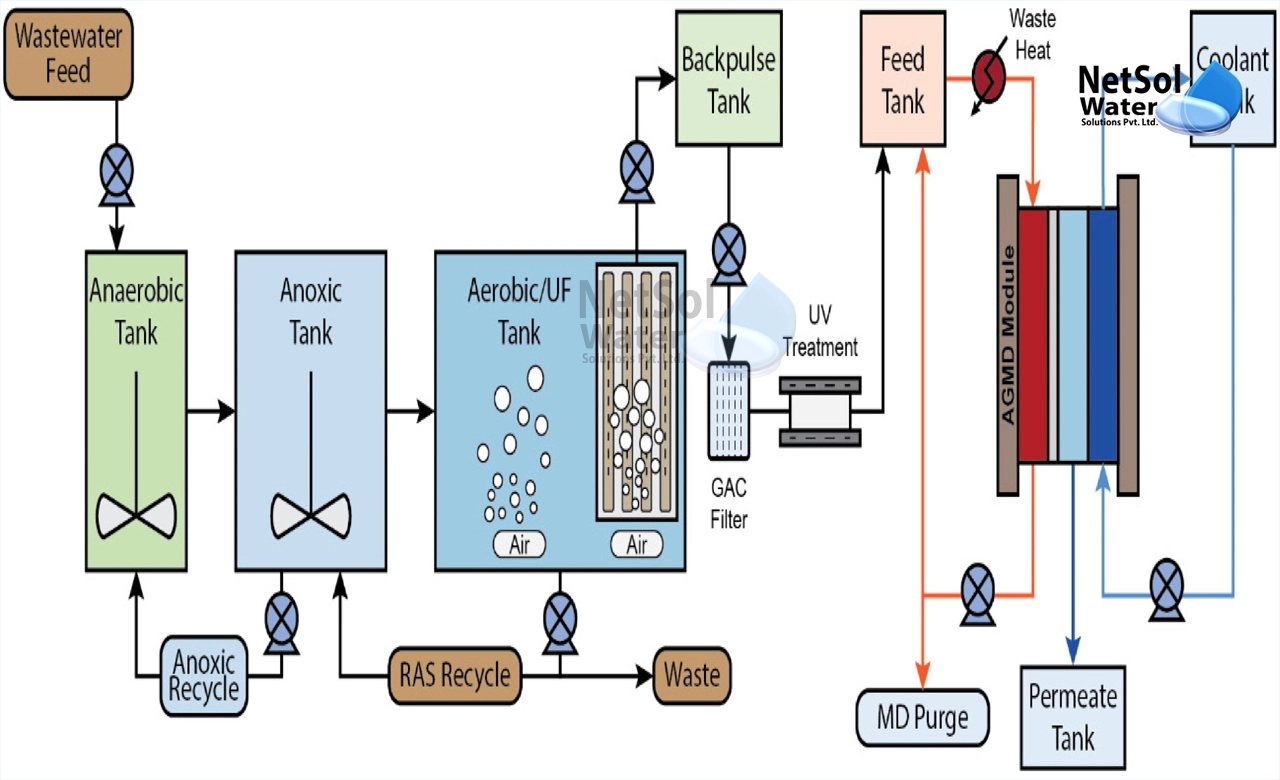

2- MBR - Membrane Bio Reactor

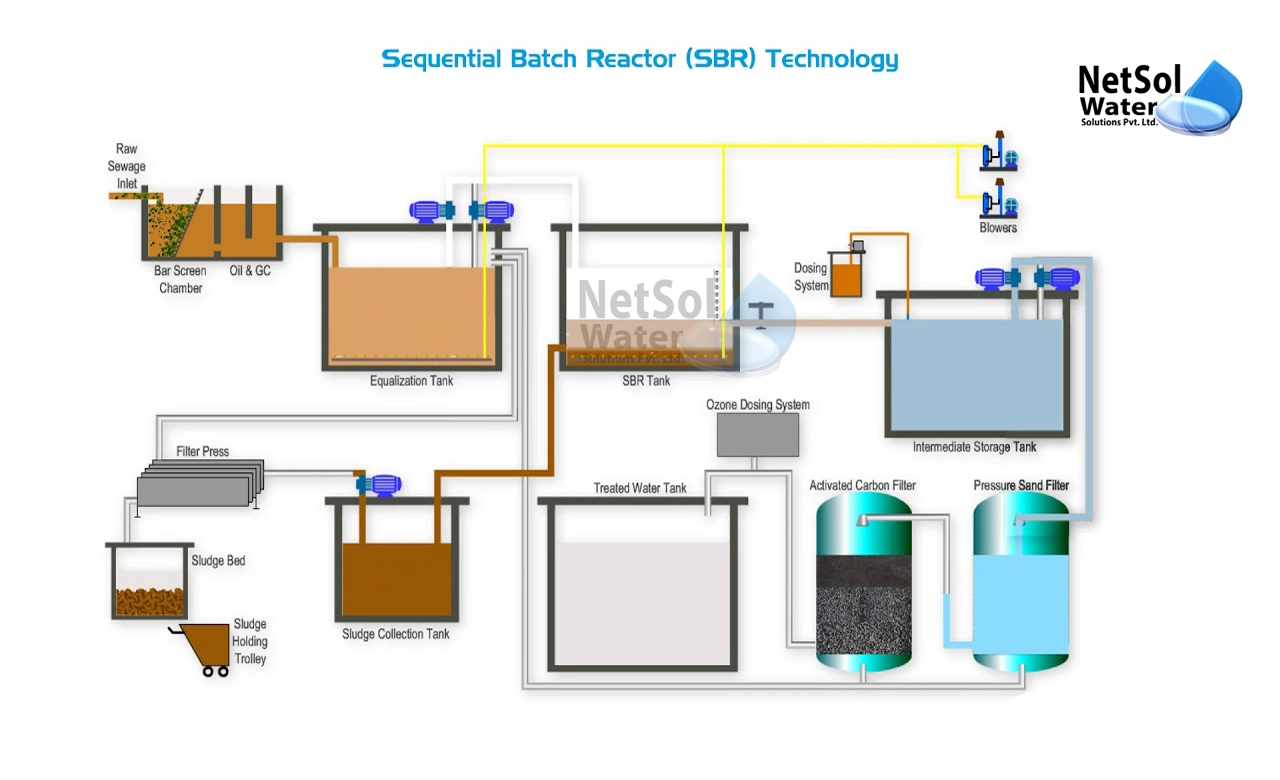

3- SBR - Sequential Batch Reactor

4- STP - Green Technologies

What are the Pollution Control Board ( DPCC) norms for STPs treated water in Delhi?

The Delhi Pollution Control Committee (DPCC) is responsible for setting and enforcing Delhi's effluent and sewage treatment standards. DPCC monitors the functioning of Sewage Treatment Plants (STPs) and the quality of treated wastewater they discharge into the environment.

As per the latest audit of STP samples by DPCC, many plants are found to be violating the prescribed norms. For instance, the Phase-IV Okhla STP was found to exceed the limits set for parameters like Total Suspended Solids (TSS), Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD).

The DPCC STP discharge standards align with the Central Pollution Control Board (CPCB) regulations. Several parameters are based on which treated sewage quality is assessed - pH value, TSS, BOD, COD, oil and grease, ammoniacal nitrogen and dissolved phosphates. The strict upper limits are 10 mg/l for TSS, 10 mg/l for BOD, 50 mg/l for COD and 2 mg/l for phosphates.

|

Parameters |

Standards |

|

pH |

6.5-9.0 |

|

BOD,mg/l |

10 |

|

COD,mg/l |

50 |

|

TSS,mg/l |

10 |

|

NH4-N,mg/l |

5 |

|

N-total,mg/l |

10 |

|

Fecal Coliform,MPN/100ml |

< 230 |

|

PO4-P, mg/l |

2 |

DPCC collects monthly effluent samples from STP inlets and outlets across Delhi to check compliance. Stringent penalties are levied on plants found flouting the norms. However, the recurring violations indicate a lack of strict monitoring and enforcement. Delhi generates over 750 MGD of sewage, most of which finds its way into the Yamuna untreated. Even treated sewage that does not meet the norms causes river pollution when discharged. In some cases, DPCC needs to crack down on defaulting STPs through heavy fines and criminal prosecution. Technical support can also be provided to upgrade old STPs. The people of Delhi deserve clean, unpolluted water. DPCC must ensure rigorous compliance with STP standards through regular audits, technology upgrades and most importantly, accountability. Delhi's environmental future depends on it.

What are the documents required to get the consent to establishment and consent to operate from DPCC ( Delhi Pollution Control Committee) and how do apply for CTE and CTO?

The Delhi Pollution Control Committee (DPCC) plays a pivotal role in regulating projects and industrial units in Delhi from an environmental impact standpoint. Any new project or expansion of existing operations that has the potential to cause pollution requires prior clearance from DPCC in the form of Consent to Establish (CTE) and Consent to Operate (CTO). Obtaining CTE and CTO from DPCC involves submitting specified documents that provide details of the project activities, site plans, proposed pollution control measures, and environmental impact assessments. The applicant must also comply with the standard procedures for CTE and CTO application laid out by DPCC, which includes site inspections and audits. The critical documents required are project details, NOCs, EIA/audit reports and pollution control measures reports. Submitting the documents timely and following up appropriately can help obtain DPCC CTE and CTO faster.

The Delhi Pollution Control Committee (DPCC) issues Consent to Establish (CTE) and Consent to Operate (CTO) to industries and projects in Delhi to regulate environmental impact. Obtaining CTE and CTO from DPCC involves submitting various documents and following the due process.

Consent to Establish (CTE)

CTE is required before commencing construction or starting new operations. The key documents needed for the DPCC CTE application are:

1- Land ownership papers

2- Project report with details of activities, capacity etc.

3- Site layout plan

4- NOCs from authorities like the fire dept, electricity board etc.

5- EIA report for Red/Orange category projects

6- Pollution control measures report

The CTE application process involves:

1- Filling out the application form available on DPCC website

2- Paying the requisite fees

3- Submitting the documents to DPCC online/in-person

4- DPCC reviews the application and inspects the site

5- CTE is issued if the project meets DPCC's environmental standards

Consent to Operate (CTO)

CTO is required before starting operations once the project is established. The documents needed for DPCC CTO application are:

1- CTE copy

2- CTO application form

3- Environmental audit report by auditors

4- Updated NOCs from authorities

5- Report on installed pollution control measures

The CTO application process involves:

1- Filing the application form along with documents

2- DPCC inspects pollution control systems installed

3- CTO issued if norms are adequately met

4- CTO specifies conditions to be followed

How to Calculate STP or Sewage Treatment Plant Capacity?

As per Pollution Control Board Norms - manufacturing industries should consider 45 Liter water per person per day whereas Group housing societies should calculate 100 liter water per person per day.

Here is the example for manufacturing industries / commercial buildings/ Corporates - if there are 200 people in any buildings/ Industries -

200 Person X 45 Liter - 9000 Liter means 9 KL So here the requirement for that Industry/ Building will be 9 KL/ day.

Same as above kindly find here the example calculation for Group housing societies -

Suppose there are 500 people residing in any group housing society

500 person X 100 Liter = 50,000. Means 50 KL. SO Building requirement would be 50 KL/Day

Cost of STP ( Sewage Treatment Plant in Delhi)

Sewage Treatment Plant cost depends upon the technology and the quality of the water the user is looking for, as a generally advanced technology STPs are available as

Rs, one lakh per KL/ KLD. But once, the capacity of STPs increases prices get lower in proportion to increase the in capacity.

Kindly find here below the cost of STP Plants based on their Capacitis/ sizes -

10 KLD - 8 Lakhs

15 KLD - 11 Lakhs

25 KLD - 14 Lakhs

50 KLD - 18 Lakhs

100KLD - 25 Lakhs

200KLD - 45 Lakhs

300 KLD - 75 Lakhs

500 KLD - 300 Lakhs

The key factors that determine STP installation costs are:

Plant Capacity

The required treatment capacity depends on the sewage generation estimate based on the number of users and water consumption. On average, 80% of the water supplied flows back as sewage. For an institution like a college, a 50 KLD (thousand litres per day) STP would suffice for 500-600 students. For large universities, the capacity could go into hundreds of KLDs. The plant cost increases in proportion to rising capacity.

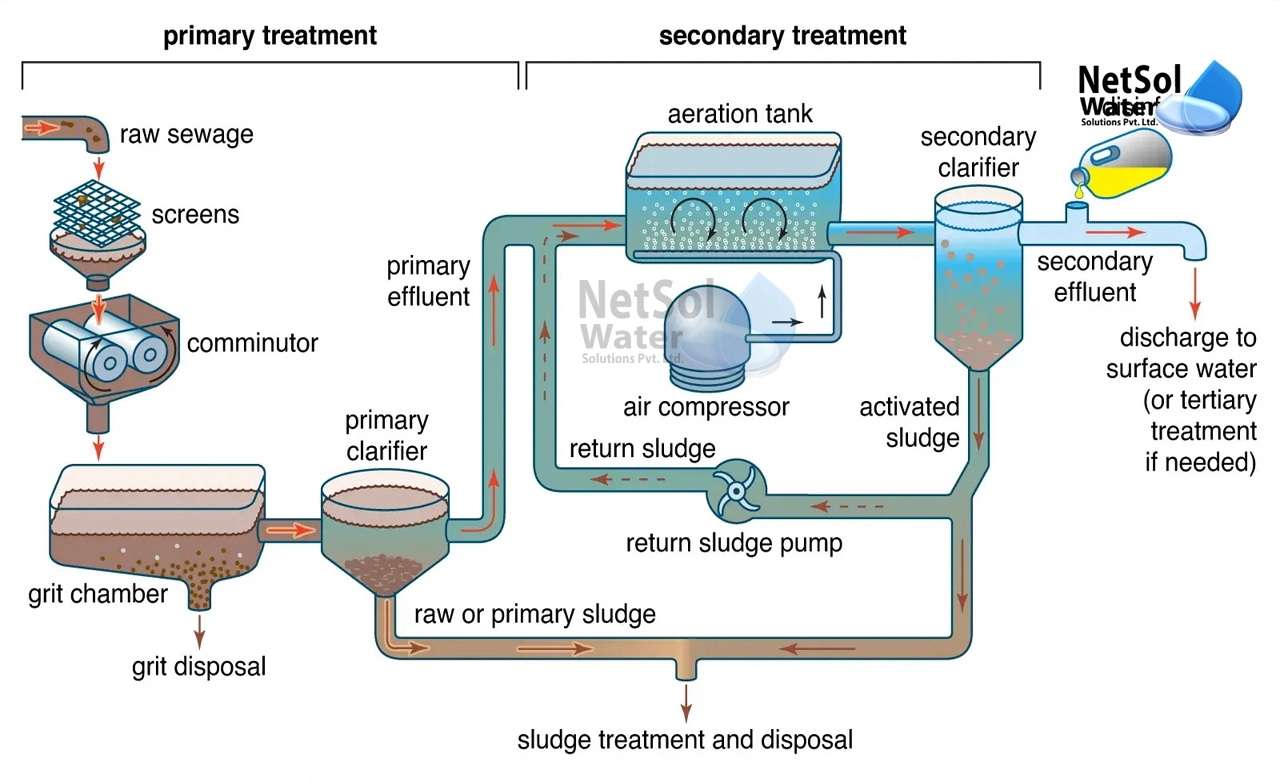

Treatment Technology Used

Simple STPs with basic primary treatment are cheaper. Advanced technologies like MBR, MBBR, SBR etc. that provide tertiary treatment and meet stringent discharge norms are costlier. The treatment modules selected depend on the effluent quality needed and the plant footprint.

Energy Consumption

STPs require power for pumping, aeration, rotating equipment, etc. Energy-efficient STPs may cost more upfront but payback through lower operating costs. Solar power can help reduce reliance on grid electricity.

Monitoring and Automation

Manual STPs require more labour and supervision. Automated plants with SCADA monitoring enable remote monitoring and reduce manpower needs despite higher capital costs.

Operational Expenses

O&M costs for chemicals, energy, spares, consumables, manpower etc. must be provisioned annually. These are over and above the one-time capital expenditure.

Evaluating the Costs for Installing an In-House STP in Delhi

For a capacity of 50,000 liters per day (50 KLD), a conventional STP based on activated sludge process (ASP) technology would cost around Rs 50 lakhs. More advanced technologies like MBBR (Moving Bed Biofilm Reactor), SBR (Sequential Batch Reactor), or MBR (Membrane Bio-Reactor) may cost between Rs 70-100 lakhs for 50 KLD capacity.

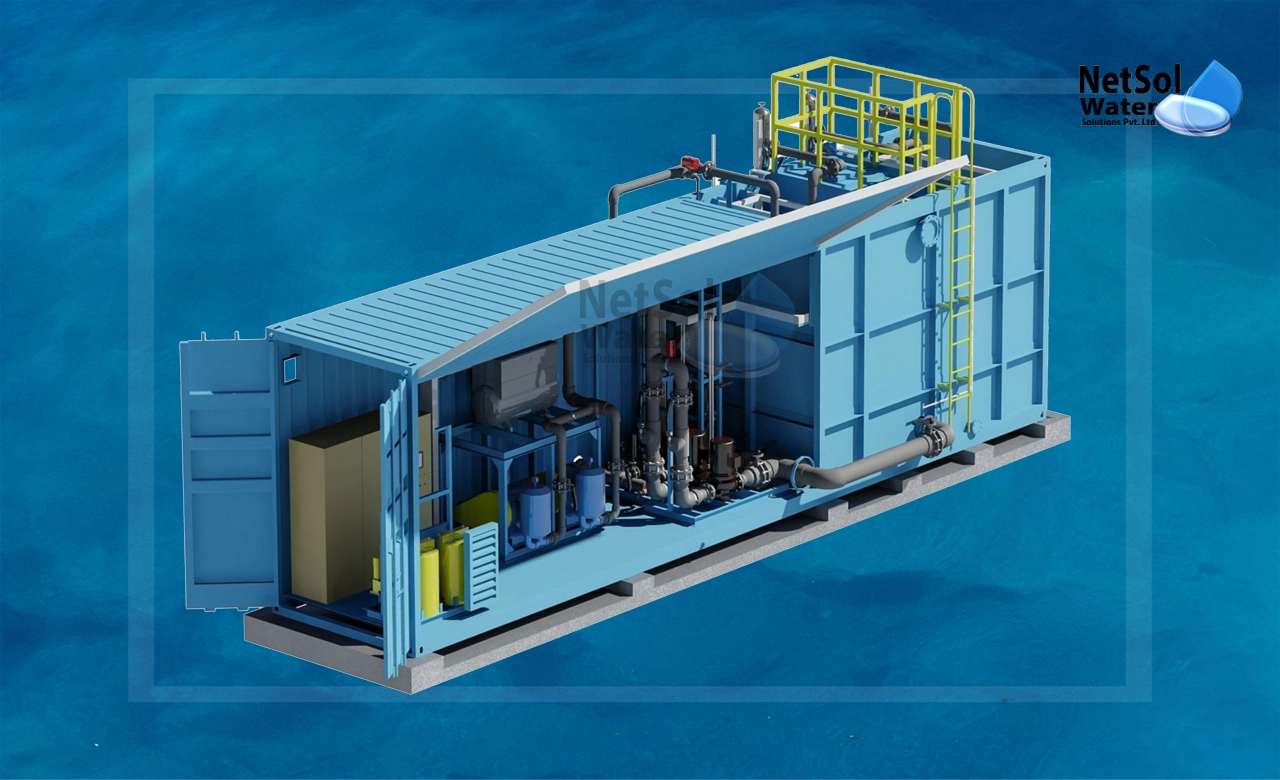

Larger capacity STPs like 500 KLD could cost anywhere from Rs 3-5 crores depending on the technology used. The recurring annual operating cost, including chemicals, energy, spares and manpower, could be 15-20% of the capital cost. Besides these, expenses related to land, civil works, pipeline connections, external power supply and automation systems would need to be provisioned for. Regarding STP technologies, the conventional ASP method relies on settling tanks and aeration to treat sewage. It requires relatively more space. Advanced technologies like MBR utilize membrane filtration to produce higher-quality treated water in compact plants, but they have higher energy requirements. MBBR uses biofilm carrier media inside the reactor for more efficient biological treatment.

SBR allows sequential treatment steps in the same reactor tank through timed control. Each technology has its pros and cons regarding footprint, energy use, automation capabilities, modularity for phased expansion, and costs. The scale of operations, quality needs and in-house capabilities influence technology selection. To reduce the financial burden, institutions can avail of partial capital grants and long-term soft loans provided by the Delhi Jal Board for decentralized STPs. Additionally, funds from CSR programs of PSUs, bank financing, alumni contributions, and vendor partnerships can supplement the project's self-funding.

While STPs involve sizable investments, the long-term dividends in water security, sustainability, cost savings from in-house water recycling, improved health & hygiene conditions and reduced burden on civic infrastructure make them worthwhile investments for campuses and complexes in water-scarce cities like Delhi.

Life of Prefabricated and Civil STP Plants in Delhi -

Prefabricated STP Life is 20-25 Years whereas in Civil STP Plants life is 25 -30 Lakhs

What is the Area Required to Install the STP Plant?

Area requirement depends on the size of the Capacity of the STP or ETP Plant, generally, it takes 1 square meter of area to install 1 KLD STP/ETP Plant.

But once the capacity is being increased area requirement goes down.

Here are a few examples that may help you to get to know the area requirements for your STP/ETP Plants -

20 KLD STP - 16-18 Square meter

50 KLD STP - 45 Square Meter

100KLD STP - 70 Square Meter

200 KLD STP - 125 Square Meter

500 KLD STP - 300 Square Meter

1000 KLD STP - 600 Square Meter

Comparison Between Prefabricated STP vs Conventional (Civil ) STP

|

Advantages |

Prefabricated MSFRP STP |

Conventional STP |

|

Installation Time |

Faster installation due to pre-fabrication and modular design. |

Longer installation time due to excavation and construction on-site. |

|

Footprint |

Compact design requires less land space. |

A larger footprint requires more land. |

|

Mobility |

Modular components allow for relocation if needed. |

Fixed location, difficult to relocate. |

|

Quality Control |

A controlled manufacturing environment ensures high-quality components. |

Construction on-site may be subject to variations in quality. |

|

Cost Efficiency |

Often more cost-effective due to economies of scale in manufacturing. |

Higher construction costs due to on-site labor and materials. |

|

Flexibility |

Easily scalable by adding or removing modules to meet changing demands. |

Limited scalability; expansion may require significant modifications. |

|

Environmental Impact |

Reduced environmental disturbance during installation. |

Significant excavation and construction can impact the environment. |

|

Operational Downtime during Maintenance |

Minimal disruption during routine maintenance. |

Longer downtime for maintenance activities. |

|

Technology Integration |

Easily integrates advanced technologies and automation. |

Integration may be challenging due to on-site construction constraints. |

|

Risk Management |

Lower risk of delays and uncertainties associated with on-site construction. |

Higher risk of delays due to unforeseen on-site issues. |

|

Maintenance |

Easy in the maintenance due to Prefabricated Structure. |

Complicated maintenance due to Civil work. |