What is the difference between SBR and MBBR?

SBR and MBBR are used as sewage treatment plants. Separating pollutants from wastewater is the only motto of SBR or MBBR sewage treatment plants. All of these have different purposes and have their own process of purifying wastewater.

What is MBBR?

Mixed Bed Biofilm Reactor: This sewage treatment plant is deployed in a very small space, known as the biofilm process. MBBR is also used as a sewage treatment facility in some local governments.

Developed in the late 1980s and early 1990s, this process uses biofilms attached to thousands of small plastic media to break down the waste at the inlet of the aeration tank. MBBR requires some monitoring butis primarily self-regulating because the microorganisms in the tank can naturally react to fluctuations in the type and amount of waste in the water.

How does MBBR work?

In the MBBR process, feed is sent to an aeration tank, also called a reactor, filled with thousands of small pieces of plastic called carriers or media. These media maximize the surface area as they provide area for microbial growth and are similar in density to water, so they mix well throughout the tank.

What is SBR?

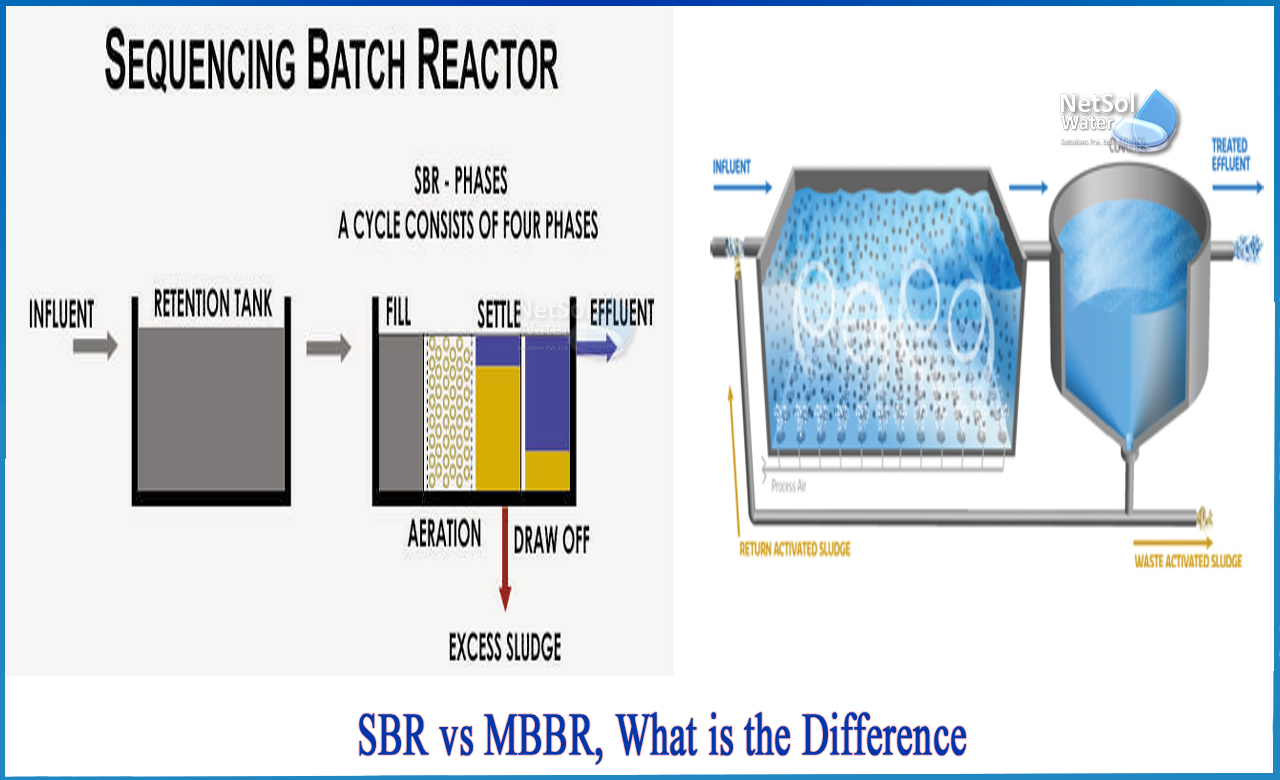

The SBR or Sequence Batch Reactor Plant uses activated sludge to treat wastewater and isused to reduce organic matter. It separates water and activated sludge through oxygen bubbles.

The Sequencing Batch Reactor (SBR) aeration system is like the activated sludge process. The main difference is that this system uses one tank for every processing step, rather than using different equipment for each step in the process. As the term "sequence" implies, SBR uses time, not space, for wastewater treatment. According to the Environmental Protection Agency (EPA), this type of system started as early as 1914. Batch reactors for sequencing are still widely used today.

The SBR system design uses a carefully timed sequence to perform all subprocesses such as equalization, aeration, and precipitation in the same tank. This usually happens in a configured cycle consisting of 5 steps.

In the SBR process, the operator first fills the tank with influent. Ventilation and microbes then begin to promote biological reactions. After completing this step, purification will take place. That is, sludge will settle. This process is usually done in a separate tank, but in SBR it is done in the same tank that acted as the reactor for the biological process.

After the treatment process is complete, the operator pumps the treated wastewater out of the tank and pumps out the old sludge. This last step in the process is called idling. After reaching this point, the SBR system can start over and re-run a series of subprocesses that introduce a new batch of feed into the tank and convert the contaminated wastewater into purified wastewater.

Like many other types of aeration processes, SBR is often part of a larger framework for wastewater treatment. Other steps, such as removing sand grains, can be done in advance, and some steps, such as disinfection, can be continued. In some cases, depending on the quality of the inflow and the desired quality of wastewater, the SBR itself may act as the only means of wastewater treatment.

The advantages of using SBR are:

-Adaptation to different supplies

-Works with automatic control

-Requires less space than a system with multiple tanks

The disadvantages of this method are:

-This requires a high degree of control and time units

-Requires more maintenance than traditional systems

-Problems such as sludge drainage at the wrong time and clogging of the aeration device are likely to occur

Netsol Water design various types of reactors and tanks for sewage treatment and waste water treatment.