What is Reverse osmosis?

When pressure drives unfiltered water or feed water across a semipermeable membrane, reverse osmosis eliminates impurities. To provide the clean drinking water, water flows from more concentrated side (more pollutants) of the RO membrane to the less concentrated side (fewer contaminants). The permeate is the fresh water that is generated. The waste or brine is the concentrated water that remains behind.

What is the mechanism behind Reverse Osmosis?

Small holes in the semipermeable membrane restricts pollutants while allowing water molecules to pass through. As the water travels across the membrane via osmosis, it gets increasingly concentrated in order to achieve the balance on both sides. On the other hand,reverse osmosis, prevents pollutants from accessing the membrane's less concentrated side. When pressure is applied to a volume of saltwater during reverse osmosis, for example, the amount of saltwater is reduced.

Reverse osmosis is a tried-and-true method of producing water that is suited for a wide range of industrial applications that require deionized or demineralized water.

After the RO system, further post-treatments such as mixed bed deionization can improve the RO permeates quality and make it appropriate for the most demanding applications. RO system's pretreatment and monitoring are critical for avoiding costly repairs and unplanned maintenance. Your RO system should deliver many years of high purity water with the right system design, maintenance schedule, and expert service assistance.

How does a reverse osmosis system work?

A pre-filter removes sediment and chlorine from water before forcing it through a semi-permeable membrane to remove dissolved particles in a reverse osmosis system. Before entering the dedicated faucet, water departs the RO membrane and then flows through a postfilter to polish the drinking water. The quantity of pre-filters and post-filters in a reverse osmosis system determines the stages.

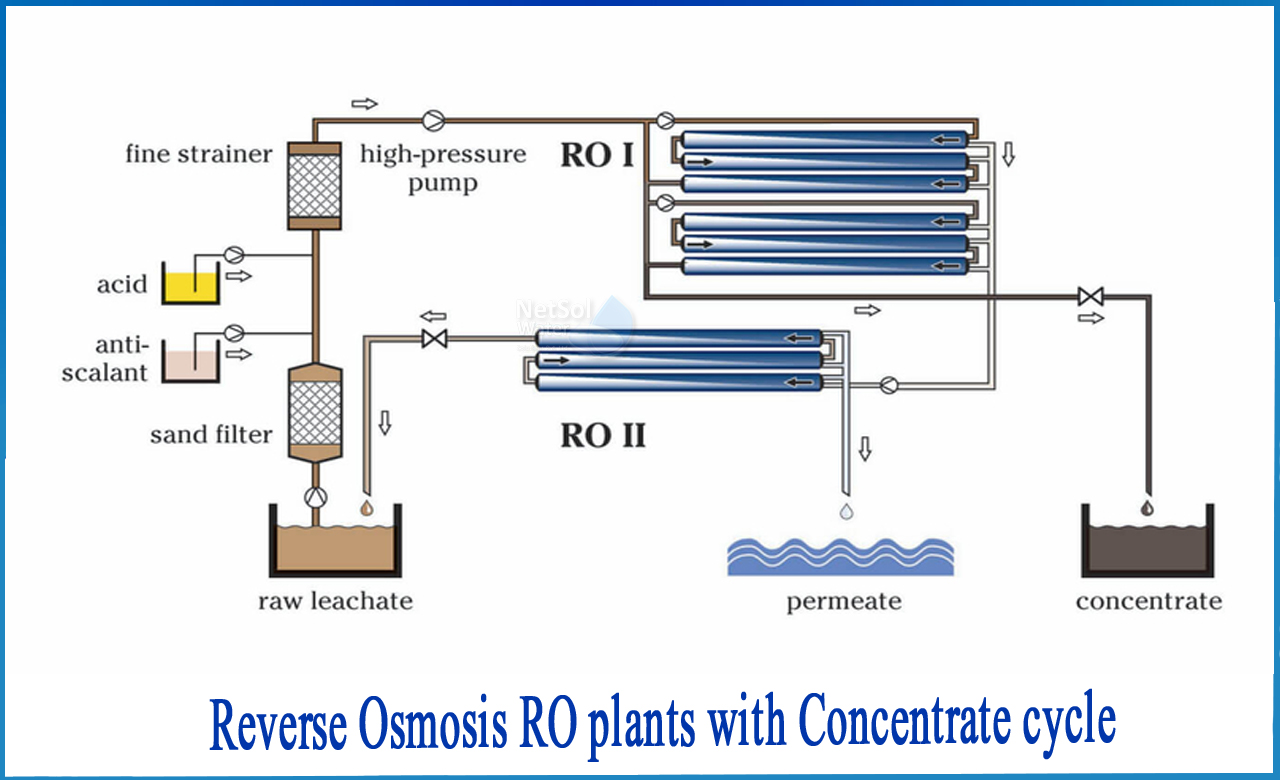

Concentrate recycling in RO systems

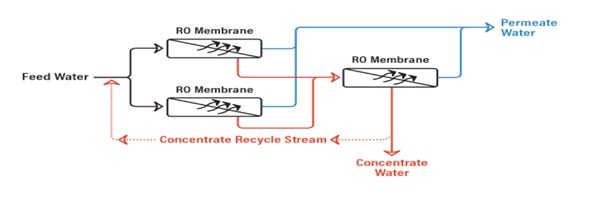

A concentrate recycling configuration may be used with RO system that can't be adequately staged. The feed water chemistry allows it, where a portion of the concentrate stream is recycled back to the feed water to the first stage to aid boost the system recovery.

What is the goal of a concentrate recycling loop?

In a reverse osmosis system, the main goal of a concentrate recycling loop is to limit the quantity of concentrate or wastewater that goes down the drain. Individual membrane recovery is reduced by using recycle loops to maintain an optimal flow velocity across the membrane surface. In a continuous loop, the recycling loop takes a portion of concentrate flow that would otherwise go down the drain and returns it to the feed of the RO pump. Reduced concentrate flow to drain results in a greater "recovery" percentage for the system. Pump size must account for the increased flow generated by the concentrate recycle loop.

The feed water analysis must be carefully scrutinized. Fouling in the membranes may only be reduced to a certain extent by concentrating the waste stream to a larger degree. Each feed water will have a different fouling point.

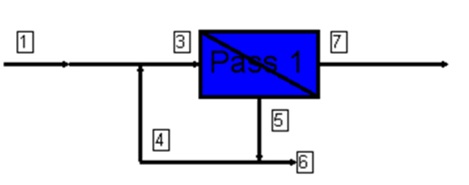

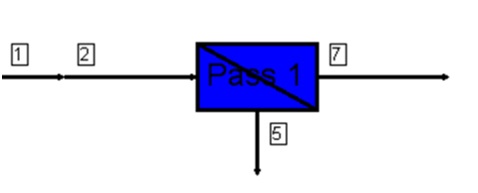

The following are two instances of the identical system working at 70% recovery, the first with recycle and the second without:

1. System Design Overview with Recycle Loop

2. System Design Overview Without Recycle

Technical assistance and guidance

Netsol Water collaborates with a wide range of international organizations to tackle complicated RO problems by strategically integrating modern treatment technology with practical solutions.

If you need any technical help and guidance, or simply have a query regarding our water and wastewater treatment technology solutions, contact one of our expert advisers via phone at +919650608473 or contact via email at enquiry@netsolwater.com