How to Realizing the Energy Efficiency Benefits of ETPs and STPs?

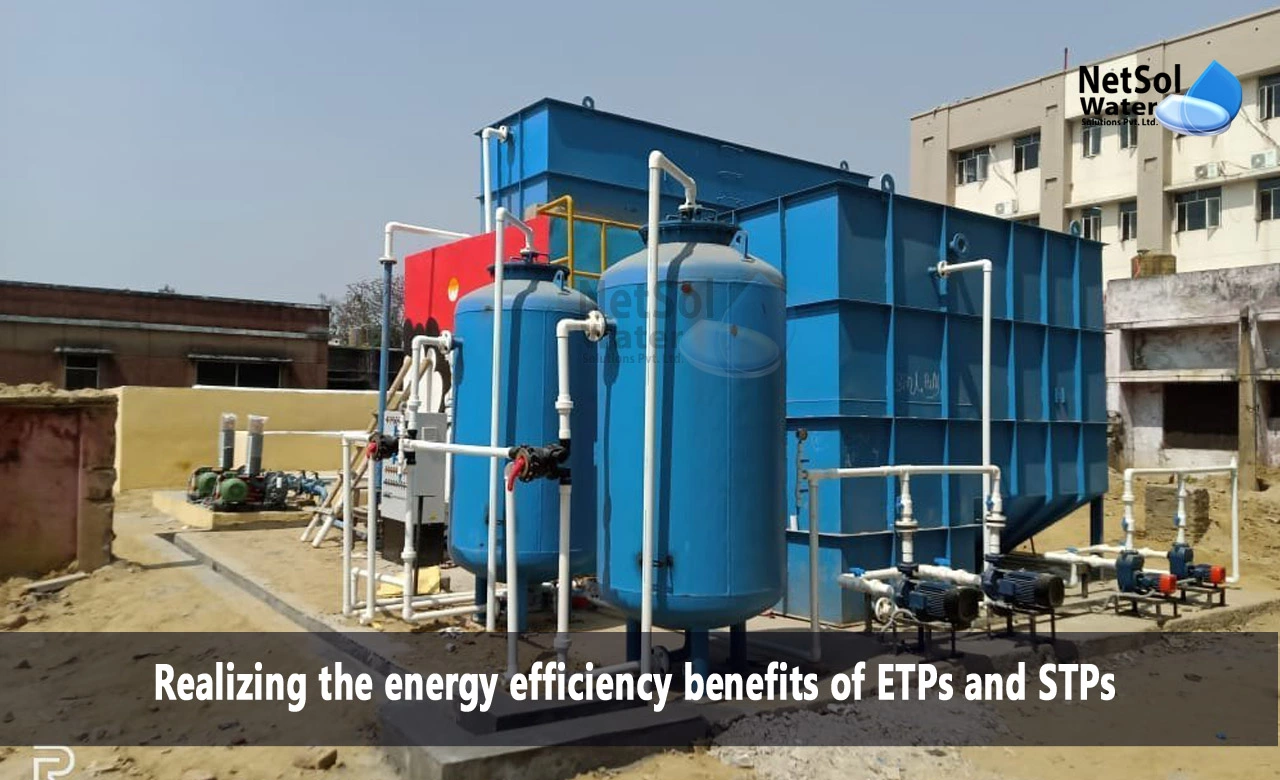

Effluent treatment plants (ETPs) and sewage treatment plants (STPs) are highly energy-intensive facilities. ETPs employ various physical, chemical and biological treatment methods to treat industrial wastewater before discharge. STPs remove pollutants from municipal sewage via screening, sedimentation, activated sludge, clarification and disinfection processes.

Both ETPs and STPs consume large amounts of electrical and thermal energy for pumping, aeration, mixing, heating/cooling and other process requirements. Energy is often the biggest operating expense for these plants after manpower costs. Optimizing energy consumption without compromising treatment efficacy is therefore a key efficiency goal.

· Major Energy Usage Areas

ETP and STP facilities have the following major energy-consuming equipment and processes:

- Pumps for wastewater intake and transfer between units

- Blowers for aeration in bioreactor tanks

- Mixers and agitators for equalization and homogenization

- Heating systems for influent wastewater or digestion tanks

- Compressed air systems for control valves, instrumentation etc.

- Sludge processing units like centrifuges, filter presses, dryers

- Lighting and utilities for plant buildings and overhead tank areas

Typically, aeration blowers account for 50-60% of total electrical energy consumed in STPs while pumps take up 15-20% share. In ETPs, the energy split between major units varies depending on effluent characteristics and treatment methods deployed.

· Opportunities for Energy Savings

Significant energy savings can be achieved in ETPs and STPs through the following measures:

1. Efficient Pumping Systems

- Using premium efficiency motors, VFD controllers

- Optimizing pump capacity as per dynamic head

- Monitoring pump performance and preventing throttling

2. Optimized Blower Operation

- VFD-based control to match air supply and demand

- DO sensor-based aeration control at aerobic tanks

- Cleaning clogged diffusers periodically

3. Efficient Mixing and Agitation

- Using improved mechanical designs like axial flow impellers

- Controlling based on torque or current optimization

4. Digester Gas Reuse

- Co-gen systems using biogas from sludge digesters

- Digester gas combustion for heating needs

5. Heat Recovery and Insulation

- Recuperating heat from flue gases or reactor jackets

- Insulating digesters, pipes and tanks to minimize losses

6. Renewable Energy Integration

- Solar PV, wind energy for electricity generation

- Solar water heating systems

7. Energy Management Systems

- Monitoring peak loads and optimizing plant operation schedules

- Sub-metering and analytics to identify high energy consuming equipment

8. Process Optimization

- Maximizing treatment efficiency to reduce recycling flows

- Optimizing cycle times to minimize running hours

9. Staff Engagement

- Trained manpower for energy monitoring and performance analysis

- Incentivizing staff for achieving energy efficiency targets

Key Benefits of Improving Energy Efficiency

1. Lower Operating Costs

Reducing electrical, thermal and other utility costs greatly benefits OPEX for both ETPs and STPs.

2. Better Sustainability Profile

Energy optimization makes treatment processes greener and aids in carbon footprint reduction for facilities.

3. Compliance with Regulations

Energy conservation norms for industries make ETPs critical to fulfill compliance for the water-intensive parent plants.

4. Enhanced Reliability

Efficient equipment like VFD-coupled pumps lowers failure rates and reduces downtime costs.

5. Water Savings

Optimized pumping and recycling minimizes reject water generation and enables reuse.

6. Profitability Improvement

Lower utility expenses directly improve the bottom line for privately owned/operated ETPs or STPs.

7. Investor Confidence

Energy efficiency makes ETP/STP projects more economically attractive for potential investors.

8. Better Work Environment

Lower noise and heat dissipation due to efficient processes enhances plant work conditions and safety.

9. Social Responsibility

Energy conservation aids the social license to operate for companies owning ETP/STP infrastructure.

Implementation Challenges

While the benefits are substantial, there are barriers to capturing energy efficiency potential fully:

- High upfront costs for retrofits and new equipment

- Technical hurdles in integrating sensors, VFDs, controls etc.

- Lack of trained staff for energy management and optimization

- Risk of efficiency enhancements affecting treatment performance

- Difficulty of verifying actual savings through robust baseline audits

- Conservative mindset resistant to changes from conventional operating practices

Realizing Efficiency Potential

To overcome these challenges, a combination of technical solutions and strategic interventions is required:

- Detailed energy audits and field measurements to identify optimization areas

- Pilot trials prior to large-scale implementation of new technologies

- Strong management commitment and staff involvement

- Phased investment plan focused on biggest saving opportunities

- Automation and data analytics to sustain efficiency gains

- Performance monitoring and optimization as a key process KPI

Given the massive energy footprint of ETPs and STPs, even 20% efficiency improvements can translate into million dollars of annual savings and greenhouse gas reduction benefits. Technical know-how, audits, analytics and stakeholder engagement are imperative to tap the energy efficiency potential of these facilities fully. Sustainable development of water-intensive industries critically hinges on efficient effluent and sewage treatment processes.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.