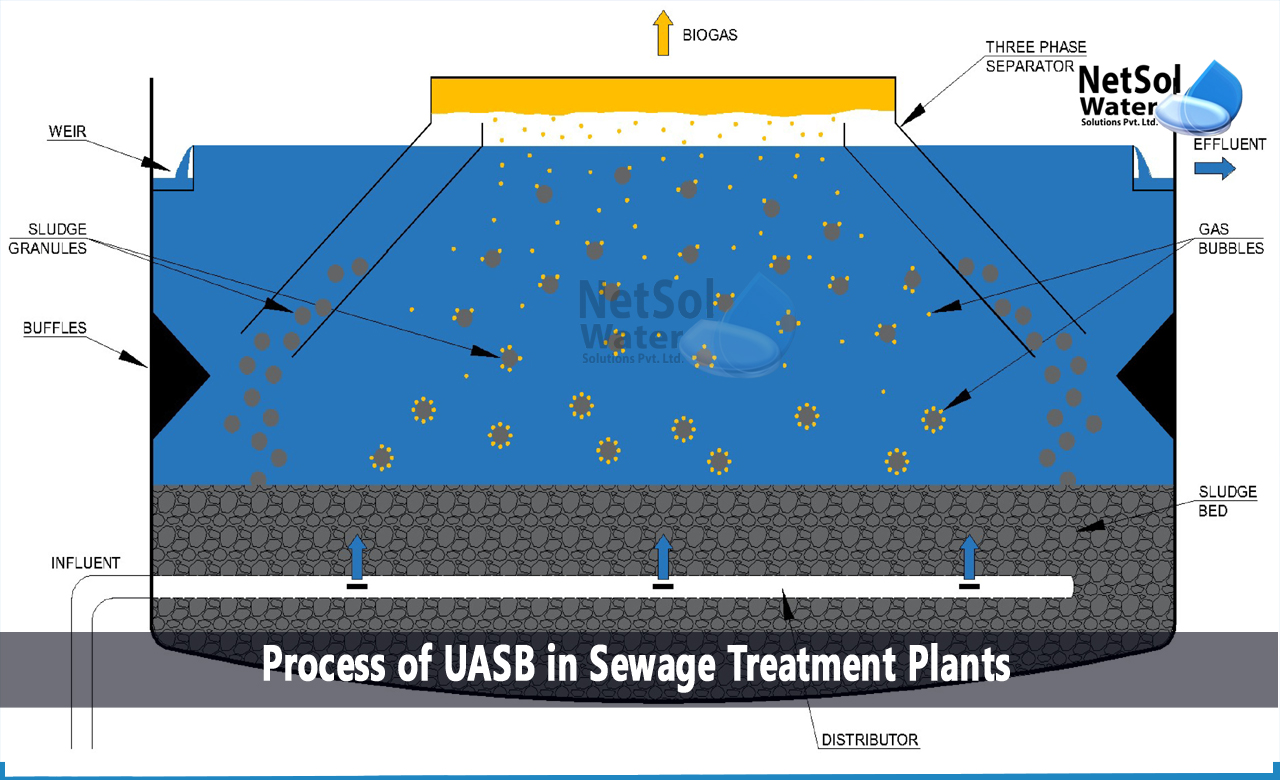

In an anaerobic centralized or decentralized industrial wastewater or blackwater treatment system, the upflow anaerobic sludge blanket reactor (UASB) is a single tank technique, which efficiently removes organic contaminants.

Let’s understand the process of UASB in the treatment of sewage!

What is UASB reactor?

The Upflow Anaerobic Sludge Blanket reactor, sometimes referred to as the UASB reactor, is a type of anaerobic methane-producing digester that produces a blanket of granular sludge, which is broken down by anaerobic bacteria.

The contact anaerobic process, which is used to treat wastewater, is adapted to use a UASB reactor. This process involves moving liquid waste upward through a thick layer of anaerobic sludge. Fine sludge particles support the growth of the biomass, which eventually gives rise to granules of high-specific gravity.

Pre-treatment in UASB rector

Although, wastewater with a high concentration of suspended solids can be successfully treated in a UASB reactor, pre-treatment methods including sedimentation and neutralization of wastewater are typically preferred.

With a removal efficiency of 75-85% and a HRT of 4 to 24 hours, organic loading in the range of 1 to 20 kg COD/m3 per day can be used.

What is the process of UASB in Sewage Treatment Plants?

Basically, the Up flow-Anaerobic Sludge Blanket operates as follows:

Step 1: Wastewater Entry

Step 2: Water flows through a layer of anaerobic sludge

Step 3: The wastewater substance is in touch with microbes

Step 4: Anaerobic digestion is used to break down organic materials

Step 5: Methane, one of the primary by-products of the breakdown process, is collected and eliminated

Step 6: The top portion of the treated wastewater is also removed

Advantages of UASB reactor

1: A significant amount of valuable biogas energy will be created throughout the treatment process, which can be captured for various uses;

2: Significantly less biosolids waste is produced compared to aerobic processes, because a large portion of the energy in the wastewater is converted to gas, leaving relatively little energy for the formation of new cells;

3: The treatment method uses less energy;

4: Reduced need for nutrition;

5: System can be shut down indefinitely without significant damage occurring;

6: Effectively able to absorb organic shock stresses;

7: May be built underground and with materials that are readily available locally, with less land demand;

8: Lowering CO2 and CH4 emissions;

9: The system can be shut down for extended periods of time without experiencing major damage;

10: The UASB reactor has a low energy need and requires little maintenance.

Application?s of UASB reactors

1. Textile industry wastewater treatment.

2. Breweries and beverage industry.

3. Treatment of chemicals and petrochemical industry effluents.

4. Distillation and Fermentation industry.

5. Food Industry.

6. Pulp and Paper Industry.

All types of high-strength wastewater can be treated by UASB reactors. It can be utilized as decentralized treatment systems for home wastewaters, or on a large scale, for example, for agricultural and industrial wastes.

Conclusion

Although, the up-flow anaerobic sludge blanket is effective in removing BOD, COD, and TSS from wastewater, it has little effect on removing nutrients. Moreover, it can handle the treatment of agricultural wastewater, industry effluent, and blackwater and greywater.

How can we assist?

Netsol Water is a top manufacturer of wastewater treatment facilities, and industrial and commercial water treatment facilities in India. Our WWTPs and ETPs effectively eliminate all kinds of chemical, physical, and biological pollutants, with the help of our advanced treatment systems, like UASB reactors.

We have become a leading manufacturer of sewage treatment plants, by providing the best materials and best construction of UASB, and have created and implemented advanced technologies in a wide range of industries.

Contact us at +91 9650608473 or enquiry@netsolwater.com for expert advice.