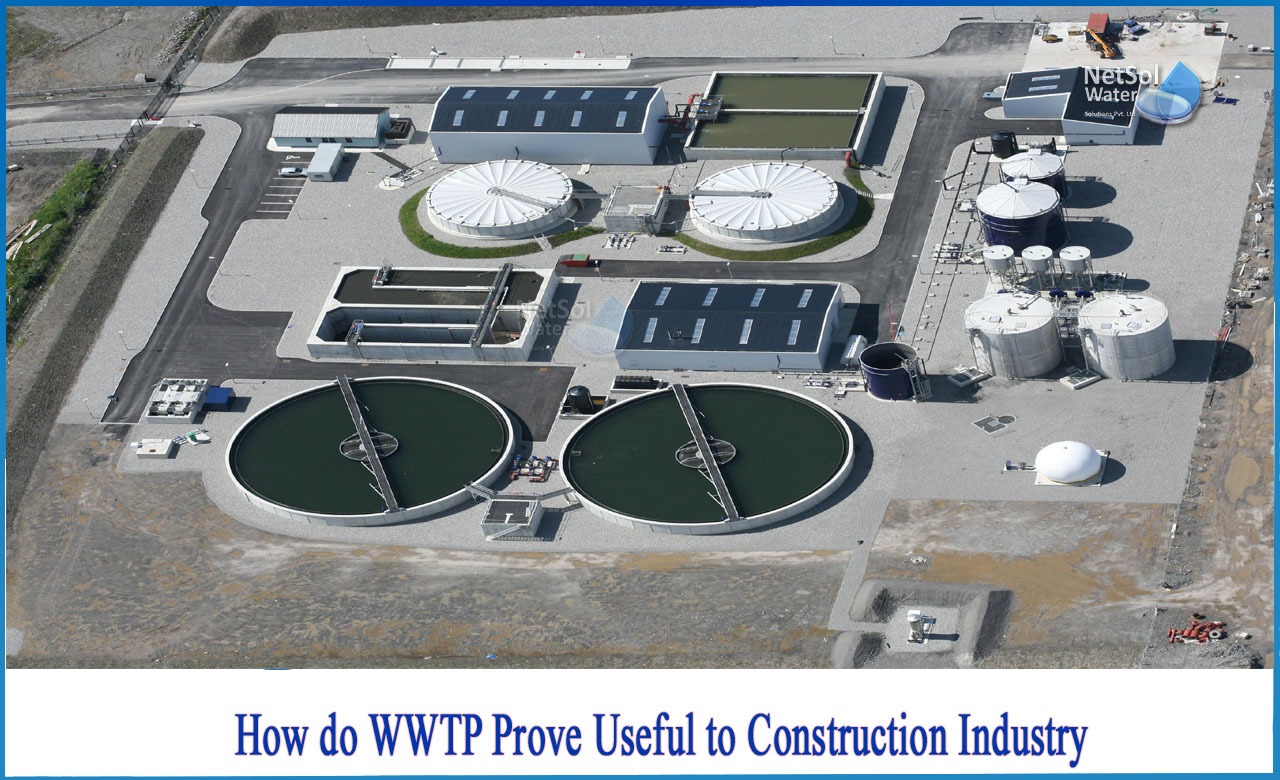

How do WWTP prove useful to construction industry?

The building industry is an integral aspect of any country's economic and social growth. Minimizing the impact on people and the environment is a major challenge in all phases of projects, including civil engineering and construction. Environmental challenges such as resource efficiency and biodiversity protection, climate change, sustainability, and the danger of accidents have grown increasingly relevant in the developed world, including building.

Why is it important to manage water in the construction industry?

Water management is an important aspect of a construction project's Environmental Impact Assessment, particularly in civil engineering.

Environmental Impact Assessment (EIA) is required for both public and private projects, as well as the creation of an Environmental Management Plan (EMP), which is a device that follows the project through all phases of innovation, implementation, and monitoring.Water is an important feature of every construction project because it is utilised as feature of the fluid for excavation and foundations, as well as to cool tools (such as tunnel boring machines, drilling rigs, and cutting machines) and clean them.

It can also emerge as a result of rain and wastewater seepage in several circumstances. In any case, it must be appropriately controlled to optimise use while avoiding environmental harm. Most nations have national and local laws that set restrictions on suspended solids (SS), acidity (pH), biological oxygen demand (BOD), and chemical oxygen demand (COD) in water that is fed into a community effluent (COD).

When these values indicate that the water cannot be dumped into a public effluent, it is frequently held in pools for natural evaporation, causing space issues and the risk of flooding. In other circumstances, classic physical and chemical treatment systems are used, which typically include a CO2 pH adjustment step, a coagulation-flocculation stage with PACs, and lamellar decantation. This form of treatment necessitates highly complex equipment, a large amount of installation space, and the difficult-to-store and-handle chemical additives required for the procedure. Furthermore, the resulting sludge must be handled and managed as garbage.

Clarification system to treat construction wastewater

The clarity method is based on the use of a single chemical additive powder that serves as a coagulation-flocculation agent and is rather insensitive to water pH, requiring no change in most circumstances. It's an inorganic chemical compound based on mollusc shells, seaweed, and minerals that's manufactured entirely of natural ingredients that's both safe and non-polluting.

It is safe, easy to handle, and does not contain any dangerous compounds to humans or the environment, thus the final sludge can be disposed of in landfills.

The entire clarity process is highly efficient and is carried out in a small machine (3.5 x 2 m), which has a significant treatment capacity (up to 90 m3/h) and is simple to transport, install, and run.

Benefits of clarification system are:

>It is eco-friendly system to treat sewage.

>It is very simple and effective.

>It is safe and very easy to handle.

>It is easy to transport, install and maintain.

>It is compact in size with larger capacity.

It becomes important to treat the waste water generated from the construction facilities to avoid deterioration of the fresh water.

For achieving such waters, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.