What are the main advantages of industrial water filtration systems?

Thousands of litres of water are often wasted each day as a result of heavy industrial or home sewage. People, whether deliberately or unknowingly, do not pay much attention to wastewater treatment. It has an immediate and indirect influence on humans, plants, and animals in the surrounding region, as well as the ecosystem. The purified water can be used for a variety of purposes. The water treatment facility, for example, renders the water reusable and safe for human use. In addition, enterprises may earn money by reusing cleaned water in their manufacturing processes.

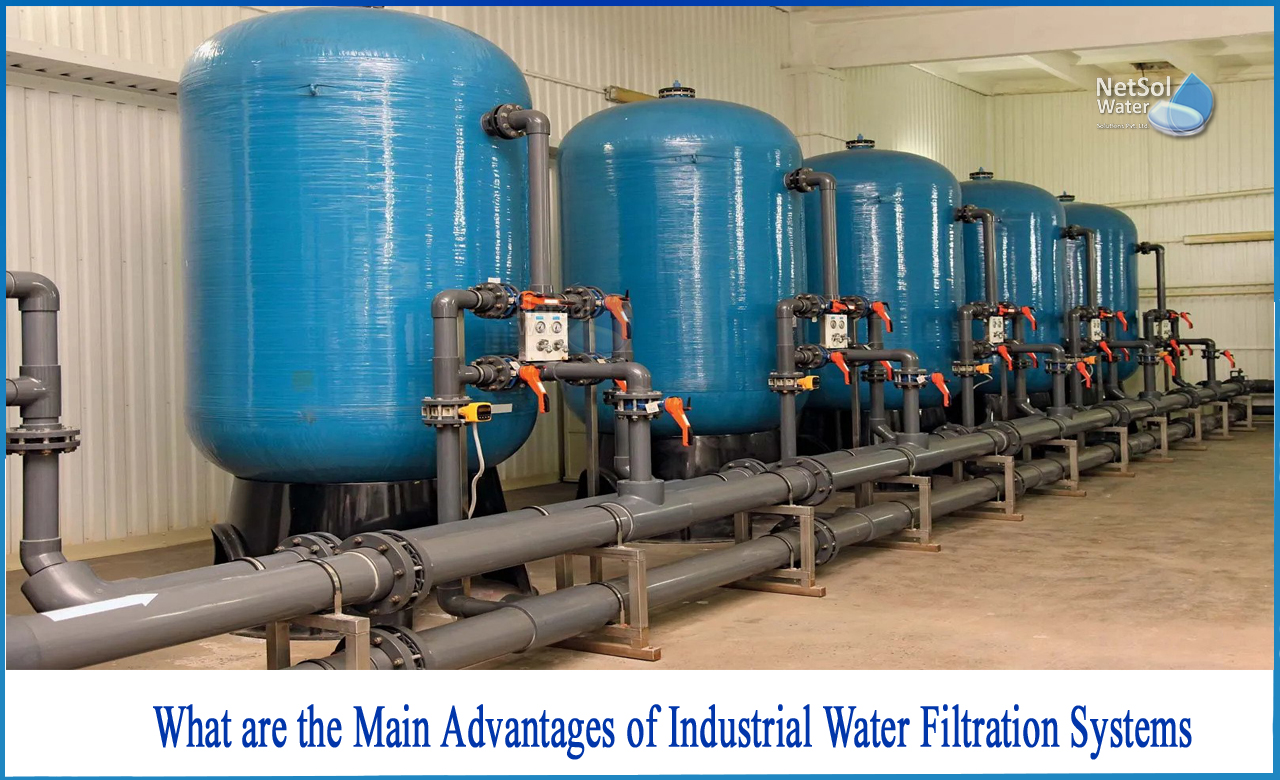

We enumerated four advantages of adopting industrial water filtration systems for businesses:

1: Improved treatment efficiency

Filtration units, when used in conjunction with other treatment systems, can significantly enhance overall treatment efficiency.The increase in efficiency can be attributed to pre-treatment or polishing. Industrial water filtration systems, used as a pre-treatment, lower the concentrations of pollutants for other polishing treatment systems in process water and wastewater applications. Many of these downstream polishing technologies work better at lower concentrations. As a result, pollutant removal rates can be boosted in this manner.

These filtering systems can be employed in a polishing process step in some situations. This is often the case in commercial/industrial wastewater treatment applications following clarity of an MBBR biological process or electrochemical treatment process.

2: Reduction of suspended solids

Industrial water filtration systems, mostly, are designed to minimize the concentration of suspended solid particles and turbidity in a source water stream. The majority of the time, filtering is just a terrific approach to reduce the burden on downstream systems in process water applications. Some sectors, such as food/beverage, pulp/paper, textiles, and oil/gas, create significant quantities of suspended particles that no treatment technology can handle. Filtration facilitates this.

3: Other contaminant reduction

Filtration systems, depending on the approach used, do not just address suspended particles or turbidity concerns.Depending on the features of the system, various types of filtration systems can also remove pollutants such as trace metals, ammonia, volatile chemical compounds, iron, manganese, and other contaminants. These filter systems are capable of reducing these specific impurities, allowing downstream polishing water treatment systems to operate more efficiently.

4: Less equipment upkeeps

When run at full efficiency, industrial water filtration systems often offer for decreased equipment maintenance of downstream treatment operations. They are often built to function in this manner for this specific purpose.

Conclusion

For more sophisticated applications, industrial water filtration systems may appear to be a simple and inadequate solution. Nevertheless, employing these systems as a complement to more modern treatment technologies has the potential to boost overall operation efficiency and lower overall running expenses. The use of industrial water filtration systems in water treatment applications may benefit both industries and commercial enterprises.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.