Process Design of Trickling Filter with various design equations

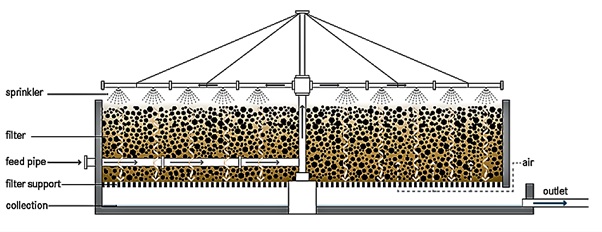

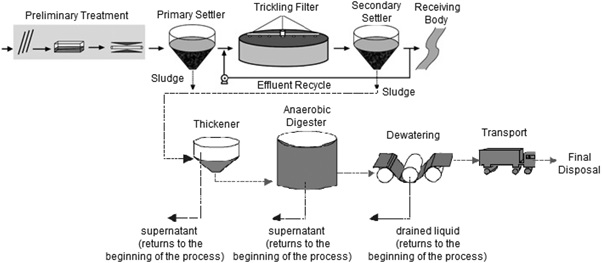

Trickling filters are typical aerobic biological wastewater treatment systems, such as rotating biological contactors or activated sludge systems. All of these systems have the benefit of being compact, making them useful in highly populated metropolitan areas. They also effectively eliminate organic debris. Although they are high-tech, they typically require expert labour both during building and operation.

In this article, let us understand the process design of trickling filter along with the various design equations.

· Pumping Hydraulics/hydraulic loading

One of the elements that will affect the performance of the filters is the hydraulic loading. It is described as the volume of waste water that is applied daily to the media's surface area. It is measured in litres per square metre every day.

The amount of biodegradation that takes place depends on how long the organic components are in contact with the microbes, which is determined by the hydraulic loading rate. The microbial layer's shear velocities in trickling filters are similarly governed by the hydraulic loading rate. The microbial layer may be washed away by very high hydraulic loading rates, before it has a chance to regrow.

To keep the microorganisms moist and to eliminate any dead or dying bacteria that have lost their capacity to adhere to the filter medium, the hydraulic loading rate must be high enough. The waste water input rate can be changed to regulate the hydraulic loading rate. To guarantee that the hydraulic loading allows enough time for an efficient bio breakdown of the organic contents in the waste water, monitoring the waste water feed rates is required.

· Organic Loading

The amount of B.O.D. applied to the filter every day per volume of filter medium is known as the organic loading. Hence, the units of organic loading are generally kilogrammes of BOD per day, per 1000 cubic metres of medium. The performance of the filter is also impacted by the organic loading.

· Recirculation factor

When the influent flow is insufficient for proper wetting, recycling treated wastewater is a useful way to maintain biological activity throughout the trickling filter's depths. These tanks need to be larger because of the additional flow required for recirculation through PSTs.

Recirculation will have no effect on the filter's volume. It is the quantity that compares the volume of re-circulated sewage (R) to the volume of raw sewage.

Process Design of trickling filters with various design equations

In order to determine the necessary filter volume for the intended level of wastewater treatment, trickling filters are typically constructed using empirical relationships. Equation types include:

· NRC formulas

· Rankine’s formula

· Eckenfelder formula

· Galler and Gotaas equation

But, commonly used equations are Rankine's and NRC. When there is no recirculation, there are less seasonal temperature swings, and there are fluctuations with significant organic loading, NRC formulae provide acceptable values. For high rate filters, Rankine's equation is employed.

· NRC equations

These equations are applicable to both low rate and high rate trickling filters. The efficiency of single stage or first stage of two stage filters, E2 is given by

E2= 100

1+0.44(F1.BOD/V1.Rf1)1/2

For the second stage filter, the efficiency E3 is given by

E3= 100

[(1+0.44)/(1- E2)](F2.BOD/V2.Rf2)1/2

Where,

E2= % efficiency in BOD removal of single stage or first stage of two-stage filter,

E3=% efficiency of second stage filter,

F 1 (BOD) = BOD loading rate of settled raw sewage in single stage in kg/d,

F 2 (BOD) = F1.BOD (1- E2) = BOD loading on second-stage filter in kg/d,

V1= volume of first stage filter, m3,

V2= volume of second stage filter, m3,

Rf1= Recirculation factor for first stage,

R1= Recirculation ratio for first stage filter,

Rf2= Recirculation factor for second stage,

R2= Recirculation ratio for second stage filter.

· Rankine’s equation

This equation has been successfully used over wide range of temperature. It requires following conditions to be observed for single stage filters:

1: Filters should not be exposed to more than 1.2 kg BOD-5/day/m3 of raw settling residential sewage.

2: A maximum hydraulic load of 30 m3/m2 filter surface/ day (including recirculation) is recommended.

3: The recirculation ratio (R/Q) ought to be set so that the BOD entering the filter, with recirculation included, is not three times the BOD anticipated in the effluent. This suggests that efficiency is solely a function of recirculation.

E= (R/Q) + 1

(R/Q) + 1.5

What are the various types of trickling filters?

Trickling filters can be divided into two types, high rate and low rate trickling filters, based on the hydraulic and organic shock load.

The organic loading rate can be defined as the kilogrammes of BOD injected per unit volume (V) in a day, while the hydraulic loading rate can be defined as the sewage flow or Q per unit volume, V, of the filter bed in a day. Both low and high rate trickling filters are around 75 to 90% effective at removing BOD.

High rate vs. low rate trickling filters

While, high rate trickling filters create partially nitrified effluent, low rate filters have a substantially higher rate of nitrification of the original effluent. Industrial wastewater and home wastewater with low to high strength levels, can be treated with low rate and high rate trickling filters.

The low rate filters do not offer recirculation of the effluent. In contrast, high rate filters have a return pump between the secondary clarifier, and trickling filter tank that helps with effluent recirculation.

The table below, which details the effectiveness and depth of the low and high rate trickling filters, can be used to determine the key differences between the two.

|

Properties |

Low rate trickling filter |

High rate trickling filter |

|

Hydraulic loading |

1-4 m3/m2.d |

10-40 m3/m2.d |

|

Organic loading |

0.08-0.32 kg BOD/m3.d |

0.32-1.0 kg BOD/m3.d |

|

Depth |

1.8-3.0 m |

0.9-2.5 m |

|

Recirculation ratio |

0 |

0.5-3.0 domestic wastewater |

With proper operation, a low rate trickling filter may remove 75 to 90% of BOD and provide highly nitrified effluent, when used with a secondary settling tank.

Although the effluent is only partially nitrified, the BOD removal effectiveness is between 75 to 90%. A main settling tank, filter, secondary settling tank, and equipment for recirculating the effluent make up a single stage unit. Two filters are connected in series to form two stage filters.

Operator duty and maintenance of trickling filter

1: It takes a knowledgeable operator to keep an eye on the filter and fix the pump when something goes wrong.

2: To avoid clogging and maintain a thin, aerobic biofilm, the sludge that builds up on the filter must be periodically washed away, once every five to seven years or more.

3: The filter can be flushed using high hydraulic loading rates (flushing dosages) > 0.8 m3/h, and temporal effluent collection. The best dose rates and flushing intervals should be ascertained by field testing.

4: Keep the packaging wet at all times. Pumps or dosing siphons regulated by suction level can maintain constant hydraulic loading.

5: When the water flow is lower at night or when there are power outages, this could be an issue. In order to prevent low flow circumstances, recirculating effluent may also be necessary, however, an excessive flow overload would flush out the bacteria.

6: In addition to drying out, anaerobic conditions brought on by high organic loadings or inadequate aeration, can also result in overwhelming odour.

Conclusion

As the microorganisms responsible for the breakdown of the organic matter are attached to the non-submerged packing material, we can infer that the trickling filter process is one of the attached growth systems. It is made to remove both suspended and soluble organic waste, and nutrients from the primary influent during the secondary treatment process.

Leading providers of Sewage Treatment Plants in India

Various businesses and industries can get in touch with the water treatment specialists, at Netsol Water for a number of cutting-edge sewage treatment methods, including aerobic and anaerobic wastewater treatment. For a range of sectors, we have also produced and designed unique biological wastewater treatment systems, like trickling filters.

We have also been offering municipalities wastewater treatment services for a long time. These services include phosphate removal, odour control, sludge dewatering, chlorination and dechlorination, and water clarification, etc. For further information, contact us by phone at +91 9650608473 or by email at enquiry@netsolwater.com.