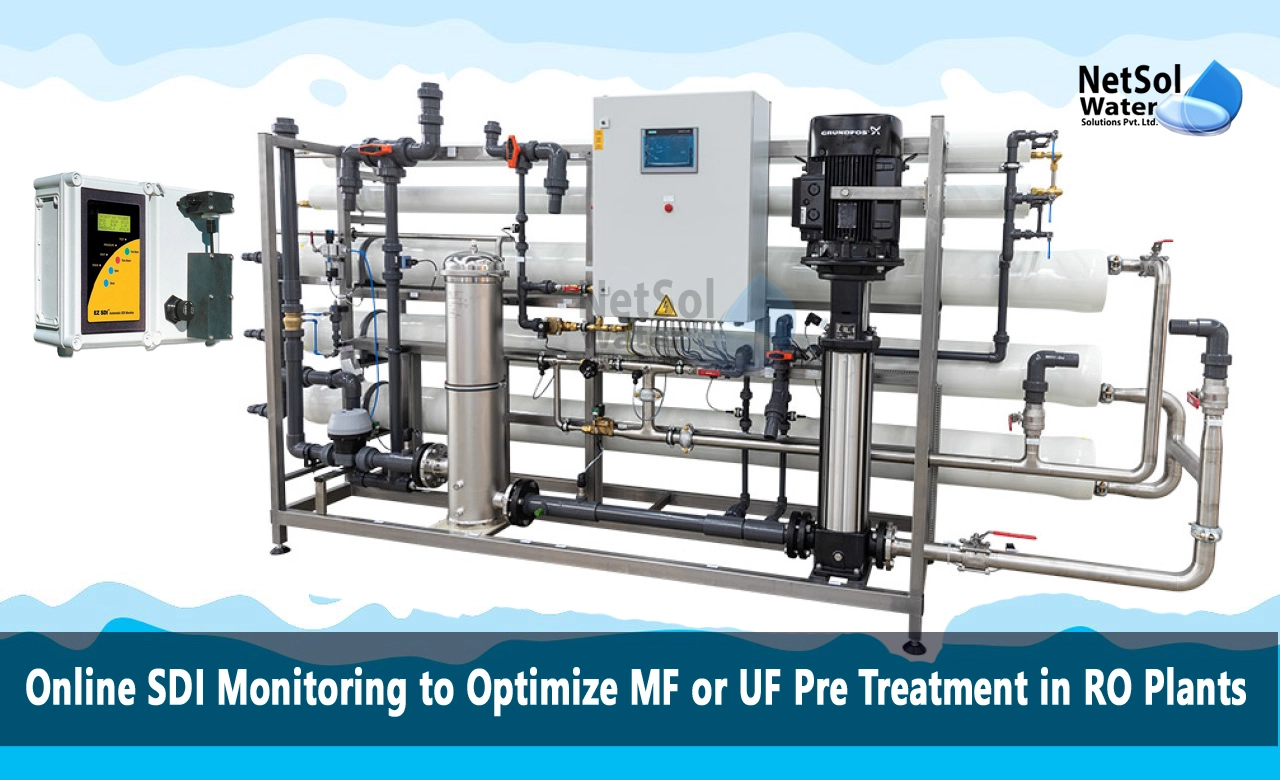

Online SDI Monitoring to Optimize MF/UF Pre-Treatment in RO Plants

Reverse osmosis (RO) is a commonly used technology for desalination and water purification in commercial plants. A major challenge with RO operation is membrane fouling, which is often caused by the accumulation of suspended solids and colloids in the feed water. Proper pre-treatment with microfiltration (MF) or ultrafiltration (UF) can help reduce particulate fouling of the RO membranes. However, optimizing the MF/UF process requires reliable monitoring of feed water quality. Online silt density monitoring provides a means for real-time optimization of the pre-treatment process prior to RO.

What is Silt Density Index (SDI)?

Silt density index (SDI) is a quantitative measure of the fouling potential of water. It indicates the rate at which a 0.45 μm filter gets clogged when water is passed through it at a constant rate and pressure. Higher SDI values correspond to a higher fouling potential. SDI is a key parameter for determining the adequacy of MF/UF pre-treatment before RO desalination. The target SDI value for RO feed is typically <3 to prevent excessive particulate fouling of the RO membranes.

Limitations of Manual SDI Measurement

Traditionally, SDI has been measured manually by periodic grab sampling followed by lab analysis. However, this approach has several drawbacks:

1- Labor-intensive and low sampling frequency

2- Time-delayed results

3- Limited value for real-time process control

4- Requires plant shutdown for grab sampling from pressurized systems

Manual sampling provides poor temporal resolution of water quality changes. As a result, excursions in SDI are often missed, allowing poor water to reach the RO.

Online SDI Monitoring

Online SDI analyzers provide continuous, real-time measurement by automating the conventional SDI test protocol. Feed water is supplied continuously to the instrument which then measures SDI at user-defined intervals, typically every 10-15 minutes. The key components of online SDI meters are:

1- Auto-backwashing filter holder with 0.45μm filter

2- Built-in pressure sensors before and after the filter

3- Precise flow control and measurement

4- Controller unit with display and data logging

The sensor system allows automated measurement of filter inlet and differential pressures. The resulting data are used to calculate SDI according to the standard method. Online SDI monitoring provides tremendous advantages over manual sampling:

1- Frequent SDI measurements for optimizing pre-treatment

2- Rapid detection of upsets for prompt corrective action

3- Enables threshold-based alarms and automated system shutdown

4- Removes sampling point as source of variability

5- Improves RO performance and reliability

Optimizing MF/UF Performance

Online SDI meters can be installed on the feed and permeate sides of the MF/UF system. Monitoring feed SDI reveals variability in raw water quality, such as seasonal or episodic events that impact silt load. Analysis of trends helps optimize coagulant dosing prior to MF/UF. Permeate SDI indicates overall MF/UF performance and filters health. Values exceeding the target indicate the need for maintenance like backwashing or chemical cleaning.

SDI measurements are also useful for optimizing flux rates through the MF/UF membranes. Higher crossflow velocity at constant TMP reduces cake formation and enables higher flux operation. However, the higher shear can also damage flocs and increase SDI. Online SDI monitoring allows real-time optimization of flux rates based on permeate quality.

Economic Benefits

Despite the higher capital cost, online SDI systems offer significant economic advantages over manual sampling:

1- Early detection of SDI excursions minimizes RO downtime and chemical cleans

2- Optimized pretreatment reduces RO membrane replacement costs

3- Higher RO recovery and permeate quality through closely monitored SDI

4- Automated system shutdown avoids RO damage from upsets

For large RO systems, the payback period for online SDI meters can be less than 12 months through reduced RO operating costs and extended membrane life.

Conclusion

Online silt density monitoring enables continuous measurement of RO feed water quality at high frequency. This allows real-time optimization of the MF/UF process for minimizing particulate fouling of downstream RO membranes. Economic analyses show that the benefits of reduced RO operating costs and extended membrane life provide rapid payback on the SDI monitoring investment. As water scarcity increases globally, online SDI metering will become an increasingly valuable tool for improving the reliability and efficiency of large-scale desalination plants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.