Mobile ETP Plant Working, Advantages and Mobility

In today's world, industries are facing significant pressure to minimize their environmental impact, especially with regard to wastewater treatment. The discharge of untreated or poorly treated wastewater can cause serious damage to the environment and public health. To address this issue, industries are turning towards mobile effluent treatment plants (ETPs) that can be moved from one location to another. In this blog post, we will discuss what is a mobile ETP plant, how it works, how it is different from a normal ETP plant, and its advantages.

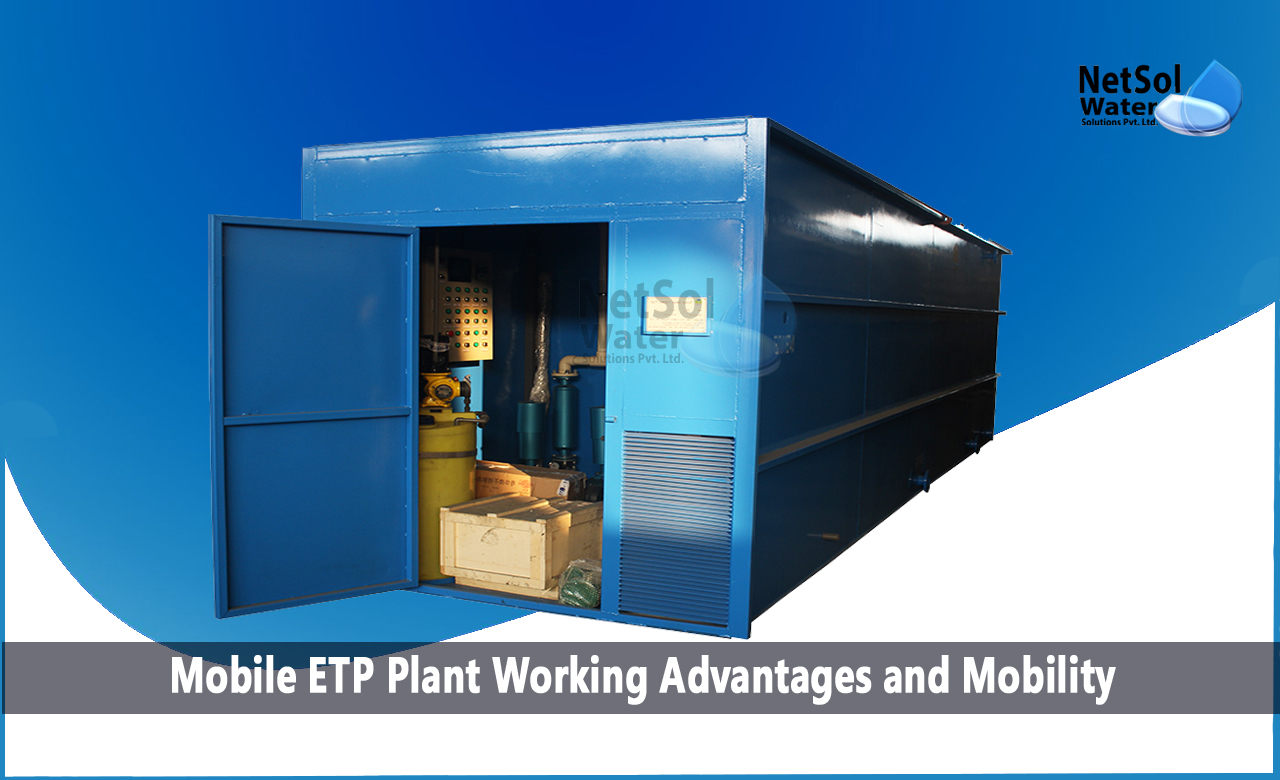

What is a Mobile ETP Plant?

A mobile ETP plant is a prefabricated wastewater treatment system designed to provide on-site treatment of industrial wastewater. It is similar to a normal ETP plant in terms of the treatment process but is compact, mobile, and can be easily transported from one location to another. A mobile ETP plant can be used in remote areas or in industries where space is limited or where temporary wastewater treatment is required.

How does a Mobile ETP Plant Work?

A mobile ETP plant is a self-contained treatment system consisting of several treatment stages. The treatment stages may vary depending on the type and characteristics of the wastewater being treated.

Typically, a mobile ETP plant includes screening, primary treatment, secondary treatment, and tertiary treatment stages as explained below:

1. Screening: The first stage of treatment involves the removal of large debris and solid particles using screens or filters. This stage helps to protect downstream equipment and reduce the load on the subsequent stages.

2. Primary Treatment: The next stage involves the removal of suspended solids, oils, and grease using physical and chemical methods such as sedimentation and coagulation.

3. Secondary Treatment: In this stage, the remaining organic matter is removed using biological methods, such as activated sludge or trickling filters. This stage also involves the removal of nutrients such as nitrogen and phosphorus.

4. Tertiary Treatment: The final stage involves the removal of any remaining contaminants or impurities, such as heavy metals, using chemical or physical methods such as filtration or disinfection.

How is a Mobile ETP Plant Different from a Normal ETP Plant?

The primary difference between a mobile ETP plant and a normal ETP plant is their mobility. A mobile ETP plant is designed to be compact, self-contained, and easily transportable, whereas a normal ETP plant is typically constructed on-site and is not mobile. In addition, a mobile ETP plant is designed to provide temporary or emergency wastewater treatment, whereas a normal ETP plant is designed for permanent wastewater treatment.

Advantages of Mobile ETP Plant:

· Flexibility: A mobile ETP plant provides flexibility in terms of its deployment and location. It can be easily transported and set up at the desired location, providing on-site wastewater treatment wherever it is needed.

· Cost-Effective: A mobile ETP plant is a cost-effective solution for industries or locations where the cost of constructing a permanent ETP plant is not feasible.

· Faster installation: Mobile ETP plants can be installed quickly, as they do not require a large construction site or lengthy installation process.

· Easy to Operate: A mobile ETP plant is designed to be user-friendly and easy to operate. It requires minimal training and can be set up and ready to operate quickly.

· Environmental Protection: A mobile ETP plant can help protect the environment by treating wastewater and preventing pollution of water resources.

· Water Reuse: A mobile ETP plant can produce high-quality treated water that can be reused for non-potable purposes, such as irrigation or industrial processes.

· Compliance: Mobile ETP plants are designed to meet regulatory requirements, ensuring that industries comply with local regulations.

How Can a Mobile ETP Plant be Moved from One Place to Another?

A mobile ETP plant is designed to be easily transported from one location to another. It is typically housed in a container or trailer that can be loaded onto a truck, rail car, or ship for transportation. The plant is pre-fabricated and pre-assembled, making it easy to set up and operate.

Summary:

Mobile ETP plants are a cost-effective and flexible solution for industries or locations where the cost of constructing a permanent ETP plant is not feasible. They can be easily transported and set up at the desired location, providing on-site wastewater treatment wherever it is needed. The treatment process is similar to a normal ETP plant, including screening, primary treatment, secondary treatment, and tertiary treatment. Thus Mobile ETP is very advantageous.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.