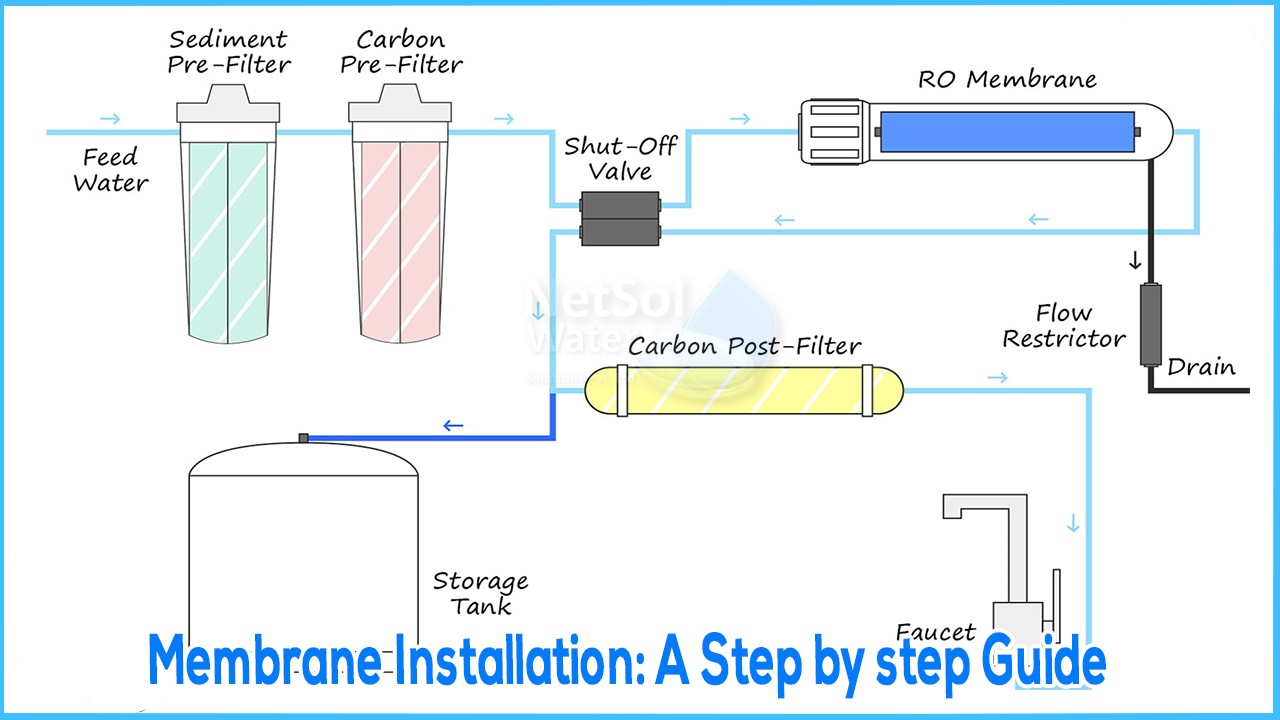

Membrane Installation: A Step by step Guide

Membranes are loaded from the pressure vessel's feed end. The following definitions will help you better understand the installation process:

- PRESSURE VESSEL COMPONENTS

1. End cap assembly

Each pressure vessel has two (2) end-caps. One end-cap is fitted on the pressure vessel's feed end, while the other is installed on the vessel's brine end. The permeate port is also located on the brine end end-cap.

2. Membrane adapter

Per pressure vessel, there are two (2) membrane adapters (also known as stub tube adapters). At each end of the pressure vessel, these devices connect the membrane product water tube to the end-cap assembly.

3. Interconnector

Each membrane pressure vessel has six (6) membrane inter-connectors. The interconnectors connect each adjacent membrane element's product water tubes.

4. Brine Seal

A brine seal is required for each membrane element (sometimes called a chevron seal). The brine seal is inserted into a groove at the element's feed end, with the open section facing the incoming feed water. Under normal operating conditions, the brine seal will expand, effectively sealing against the inside wall of the pressure vessel and preventing feed water from flowing around the outside of the element, forcing all feed water via the membrane brine channel.

-

STEPS FOR MEMBRANE INSTALLATION

- 1. Make sure all of the pressure vessels are appropriately positioned. To identify all vessel components, refer to the pressure vessel manufacturer's instructions in the appendix. Check the fit of all O-rings on the end caps. Glycerine should be used to lubricate all O-rings. Install the downstream end-caps (concentrate/brine end) according to the manufacturer's instructions.

- 2. Insert the big PVC thrust cone into the pressure vessel's feed end.

- 3. Drain the preservative – commonly sodium meta-bisulfite solution – by unwrapping the membrane elements and placing them on a clean surface. When working with the elements, latex gloves should be used, and the environment should be maintained clean.

- 4. First and foremost, all membranes should have brine seals on one end, which will serve as the feed end. Glycerine should be used to lubricate the brine seals.

- 5. Connect one of the membrane adapters to the downstream end of the first membrane (stub tube adapters). All O-rings should be lubricated. The membrane adapter will be pushed into the membrane's product water tube. Next, insert the thrust cone and membrane element into the pressure vessels feed end, about halfway through the membrane element.

- 6. Connect the interconnector to the feed end of the first loaded membrane. The next membrane will push against the first, and the inter connector will join the two membranes. Push the second membrane into the pressure vessel, keeping it aligned until half of the membrane is within.

- 7. Push the final membrane into the pressure vessel using the same approach as before. Install another membrane adapter on the feed end of the last membrane (stub tube adapter). This adapter will connect the membrane to the feed end of the pressure vessel's end cap assembly. Push all membranes from the feed end into the downstream (brine/concentrate) end-cap until the lead end membrane adapter is seated. Tap the downstream end cap to help align it with the adapter if seating the adapter in the end cap proves problematic.

- 8. Install the feed end end-cap assembly at last.