Overview_

Reverse osmosis is a natural process that involves fluid movement through a semi-permeable membrane barrier to remove a wide variety of salts and produce water of high purity.

When you use a simple thin semi-permeable membrane like a sausage skin to separate a salt solution from pure water, the pure water flows through the membrane and seeks to dilute the salt solution. If the salt solution is attached to a vertical pipe, the diluted solution will gradually fill the pipe until the 'osmotic pressure' pulling pure water through the membrane equals the diluted solution's head pressure.

What determines the Layout of RO plant?

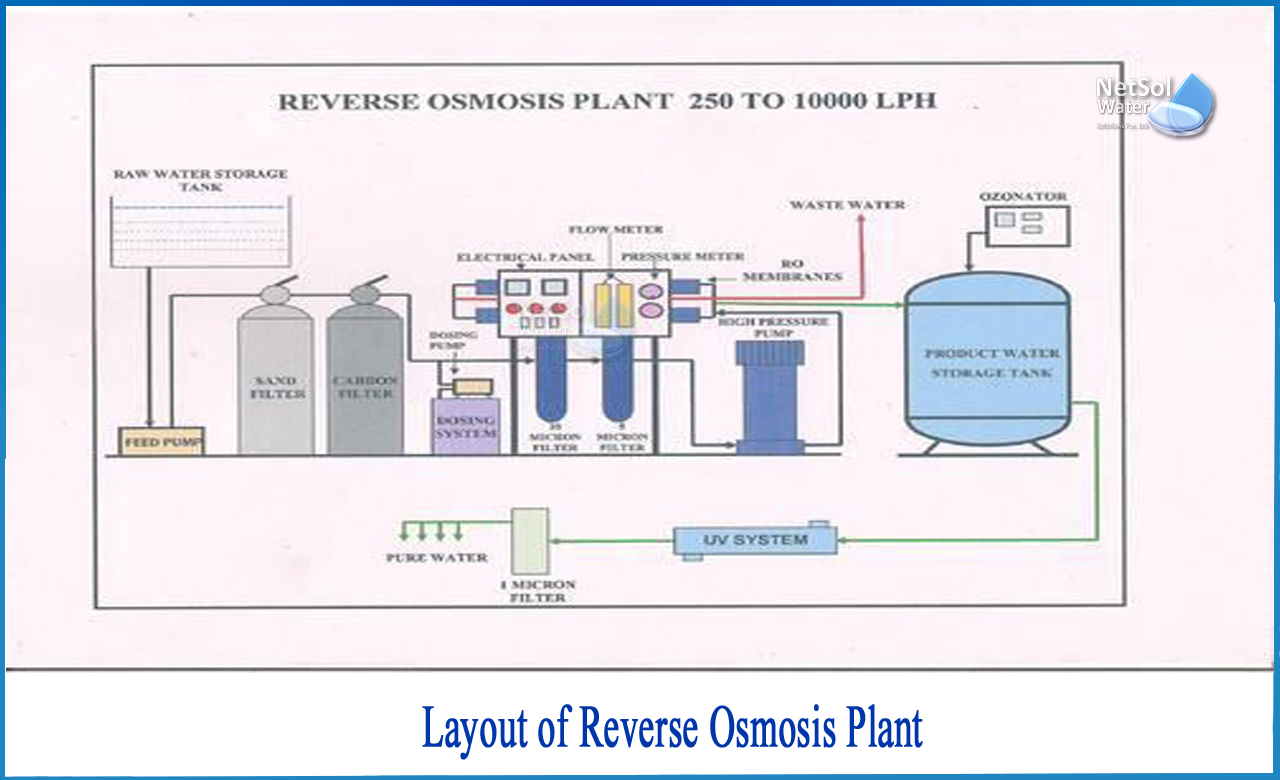

The dissolved solids and suspended solids content of the source water, as well as the degree of treatment required to condition the product water for its ultimate use, determine the layout and space requirements of the components in a facility using desalting technology to produce drinking quality water. The many components of a desalting process provide a lot of freedom when it comes to the overall architecture and look of the plant.

What does the treatment functions of RO Plant include?

The treatment functions of RO plant include pretreatment of raw water, the RO treatment process, permeate post-treatment, and concentrate treatment. The RO treatment process is included in all RO plants; however, the additional treatment functions might vary significantly depending on site-specific circumstances and the quality of the raw water. Clear raw water, for example, can eliminate the need for pre-treatment.

To create a good RO plant architecture, the designer must think of all of the treatment functions and components as a single unit that will work together. The designer must pick the precise equipment needed and construct a plant architecture to match the unique demands or space availability of the site after all of the treatment functions and components required to support the RO treatment process have been determined.

The system must be built to suit the owner's demands in terms of investment costs, operational expenses, and environmental compatibility. Any component of RO plant that isn't connected to the rest of the system is unusual.

The RO membrane housing is the most fundamental part of RO system. The cylindrical form of most commercial membrane housings leads to a rather common layout for small RO plant skids.

Depending on the kind of membranes, there are two fundamental layouts for membrane housings.

The diameter of hollow fibre membrane housings is normally 12 inch (30 cm) and the length is usually 30-48 inch (76-120 cm). Thin film membranes have a diameter of 4, 8, or 8.5 inches (10, 20, or 21.5 cm) and are inserted in tubes that range in length from 120 inches (305 cm) to 280 inches (711 cm).

A 25,000-gal/day (113 650 L/day) unit utilizing 4 inch (10 cm) thin film membranes is seen next to an 80,000-gal/day (363 680 l/day) skid using hollow fiber membranes.

A compact RO skid may be constructed in a number of configurations, such as low height with broad base or high height with narrow base, because the membrane housing units are connected to one other or to pipe headers via pipes or flexible hoses.

Size and specification_

How is size of the RO decided?

The size of the RO and the membrane to use will be decided by the amount of permeate required, the salinity of the feed water, and the expected permeate quality. Low-energy membranes allow the units to operate at pressures of 150-200 psi, reducing the size of the pressure booster pumps necessary to provide clean water and lowering power usage.

The best commercial RO plant manufacturers in India!

Our plants are made with great care and attention to detail, which is why they function so well. Our systems can provide clean, pure, filtered water if your company uses it. Filter your water to remove hazardous impurities and get the purest water possible.

These plants are both cost-effective and efficient, capable of generating thousands of litres of pure, filtered water.