How does a sewer vacuum pump work?

Vacuum sewerage systems are made up of a vacuum station, which generates the vacuum, a vacuum pipeline system, collecting chambers with collection tanks, and interface valve units. Unlike traditional gravity sewage systems with intermediate pumping stations, the vacuum system's permanent pressure is kept below air pressure. Furthermore, vacuum technology significantly minimizes water usage, allowing for variable installations independent of topography or water supply. Furthermore, it enables for the employment of alternate wastewater treatment methods (blackwater and greywater separation).

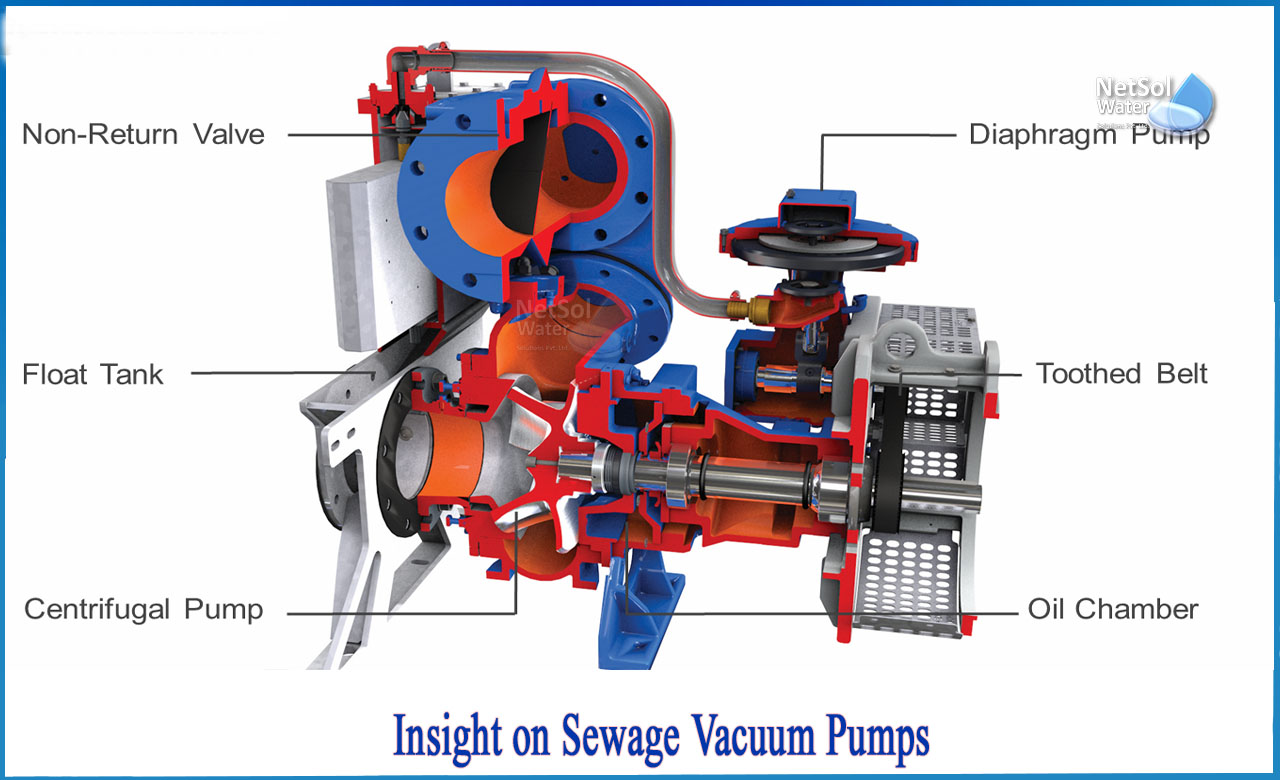

Working of vacuum pumps

Vacuum sewerage systems transport sewage from individual residences to a central collecting point using a central vacuum source. It is a mechanized wastewater transfer system. Unlike gravity flow (e.g., conventional sewers, separate sewers, or simplified sewers), vacuum sewers transport sewage using differential air pressure (negative pressure).

To maintain vacuum (negative pressure) on the collecting system, a central source of power to run vacuum pumps is necessary. A typically closed vacuum/gravity interface valve is required at each entrance point to seal the lines and maintain vacuum. When a certain volume of sewage collects in collecting sumps, these valves, which are positioned in valve pits, open. The ensuing pressure difference between the atmosphere and the vacuum becomes the driving force that drives the sewage towards the vacuum station.

What are the advantages?

Lower costs: To convey wastewater from households, buildings, factories, and streets to the water treatment plant, gravity sewer systems must operate properly. Pipelines, conduits, pumping stations, force mains, and all other infrastructure must be maintained on a regular basis. The waste, on the other hand, is pulled by one or more sewage vacuum pumps positioned in a central station in the vacuum sewer system.

The vacuum system may be built in the same trench as water supply lines, saving money on construction. Slope gradients must be maintained over extended distances in the case of gravity sewer. Vacuum pumps, on the other hand, are employed in centralized places to suck sewage from the source to treatment plants. This removes the need for slope gradient pipelines, pumping stations, and massive amounts of water to convey sewage.

Less water waste: At a time when cities all over the globe are experiencing a water problem, the vacuum sewer system is the option to consider. The vacuum sewer system transfers waste water by the use of air pressure rather than gravity-induced water flow.

This means that vacuum sewage systems have a clear advantage over traditional gravity systems in terms of water usage.

No water pollution: When correctly maintained, a vacuum sewer system reduces the possibility of water contamination due to leaks. Because it is a sealed system, there is essentially little chance of sewage interacting with groundwater or storm water. Infiltration increases the cost of filtration in a typical sewage system.

Manholes are not necessary: Manholes are required for gravity sewer systems. Failures occur at the conduit level in these systems, necessitating periodic maintenance and replacement. The vacuum sewer system eliminates the need for manholes, making system maintenance easier and safer for technical workers. The vacuum sewer system, unlike manholes, is flood-proof. It prevents floodwaters from entering the sewage system.

Defect detection is quick:When a fault occurs in a gravity sewer system, it is difficult to establish where it occurred. Faults in vacuum sewers are most commonly found at the suction valves and are easily diagnosed. Furthermore, the flaws may be repaired in a more secure and sanitary manner.

Easy operation and maintenance: Sewage vacuum pumps are simple to install and run since they may be inserted in existing channels. A single vacuum pumping station can replace six to eight gravity lift stations. Furthermore, electricity is only required at the centre site. All of this translates to inexpensive installation and operating expenses.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.