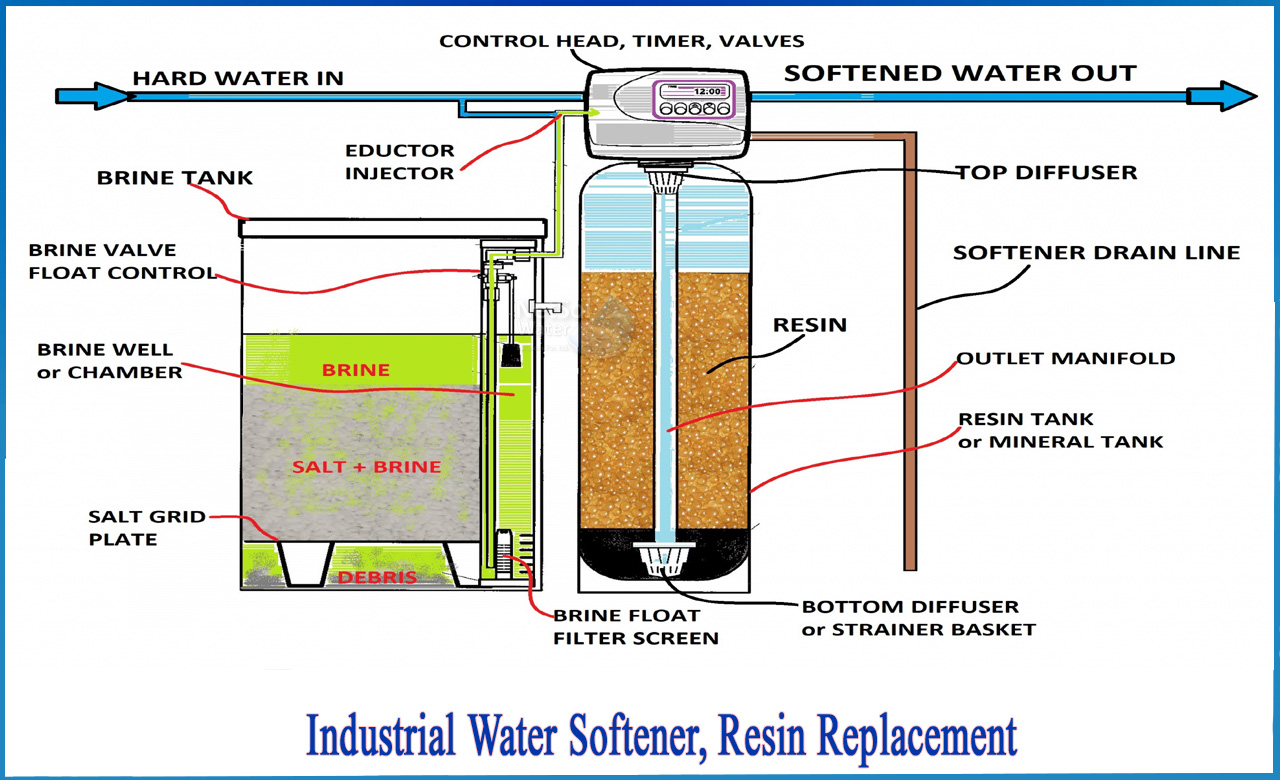

Industrial water softener

The water softener reduces dissolved calcium, magnesium, and to some extent manganese and iron ions in hard water. Metal ions most visibly react with soaps and calcium-sensitive cleaning agents, hindering the formation of bubbles and forming precipitates. This is the well-known "bathtub ring". The presence of "hardness ions" also impairs the cleaning effect of detergent formulations.

Second, calcium carbonate and magnesium carbonate tend to settle as hard deposits on the surface of the tube and the surface of the heat exchanger. This is mainly caused by the pyrolysis of bicarbonate ions, but it can also occur in the absence of such ions. The resulting build-up of scale can limit the flow of water in the pipe. In the boiler, the deposits act as insulation, preventing heat from flowing into the water, reducing heating output and overheating metal boiler components. In pressurization systems, this can lead to boiler failure.

With proper pre-treatment and maintenance, the average water softener resin does not need to be replaced during its lifetime (more than 20 years). Since many factors are involved in the destruction of the resin itself, it is impossible to accurately determine the life of the resin.

Proper pre-treatment can be as simple as a precipitate filter or as complex as a chemical injection system in combination with a multimedia bed. This is determined by a water quality test.

Industrial water softeners use resin that needs to be replaced on a regular basis. This replacement process is known as water softener re-bed.

Netsolis an industry leader in commercial and industrial softeners, filters and reverse osmosis systems. Expertise is important because embedding and reconstructing industrial water systems is as artistic as engineering. For this reason, Netsolis a clear choice for the relocation, replacement and restructuring of industrial water systems.

When do you need re-bedding?

Industrial water softener resins usually last 8- 14 years, depending on other factors such as the chemistry of the water and the level of oxidation in the water.

Why do I need to replace the water softener resin?

As the industrial water softener resin ages, the resin also ceases to function. This old resin loses capacity and has more pressure drop than the new resin. Resins are also less efficient in terms of salt and water consumption.

Do I need to test the resin before replacing it?

It is possible to test the resin, but in many cases the resin has not been tested prior to replacement. This is because testing the resin is expensive and time consuming. Therefore, if the softened resin is in the 8 -13 range, it may be more cost effective to simply continue to re-bedding.

If your car has 50,000 miles of tires and you're already driving 60,000 miles, you don't need to check if the tread is worn. Unlike tires, checking for resin wear is not easy just by looking at it. It takes a lot of time and money. Therefore, testing is usually limited to large systems that require a more expensive burden.

How is industrial water softener resin replaced or re-embedded?

The resin (and possibly gravel) is pumped or vacuum trucked and discarded accordingly. Unless the pipe contains resin or gravel, it is usually not necessary to remove the gravel. We do not recommend doing this unless you really need it. Getting out is not easy and often ends after removing the gravel unless the power distribution system is broken. Once the gravel has been removed, plan to replace the sub-drain.

Then the system reboots. This is a detailed process that includes adding gravel/media, filling tanks, and returning fabric softener online. This process is performed by a trusted and competent salesperson to make this as easy as possible.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.