Overview

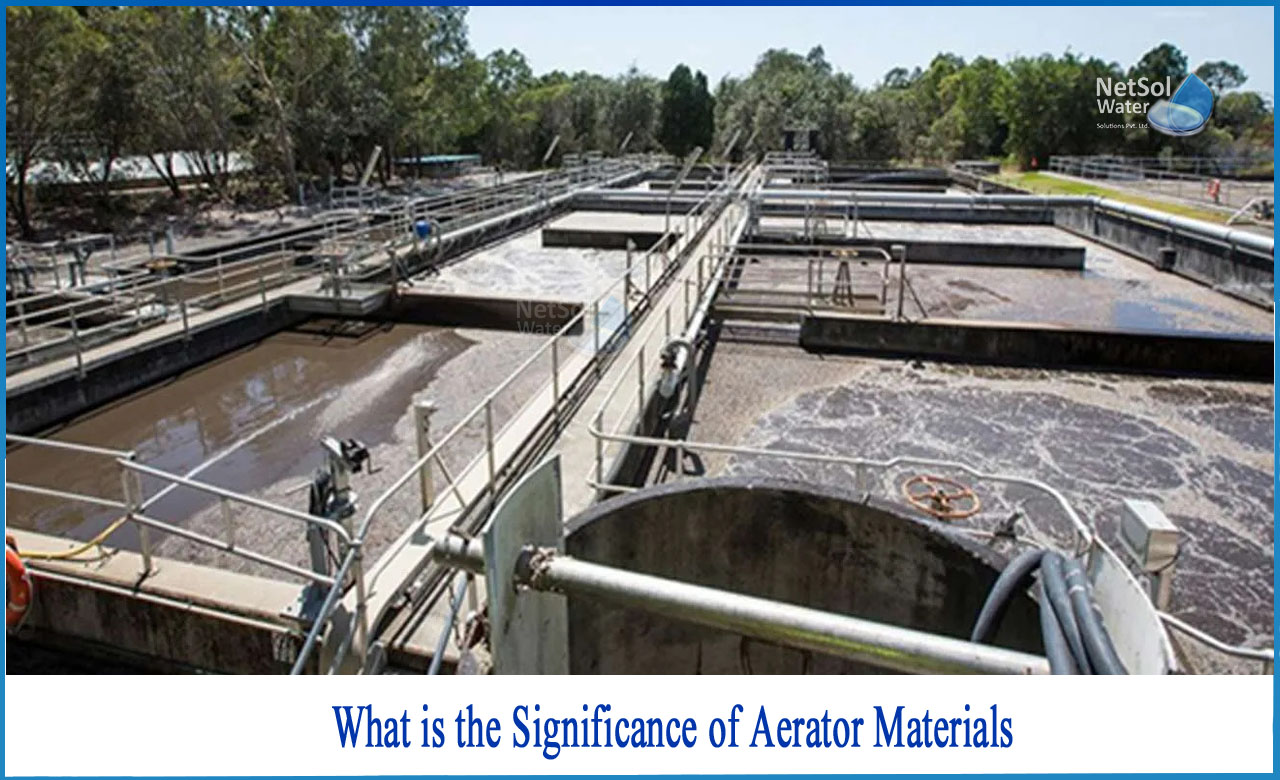

Aeration of wastewater happens when air is given directly to the wastewater, allowing for aerobic biodegradation of any contaminants present. Aeration is an important part of the wastewater treatment process.

What is the advantage of aeration?

The fundamental advantage of aeration is that it is a natural way to remove contaminants from water or wastewater. When used in large quantities, the chemicals employed in alternative treatment techniques can be dangerous. The aeration technique, on the other hand, uses microorganisms that already reside in the wastewater to decompose the toxins.

Aeration is significant because, when compared to other possibilities, it is extremely effective, economically viable, and environmentally friendly. The aeration process provides oxygen to bacteria, which aids in the treatment and stability of wastewater. To complete the bio-degradation process, the bacteria require oxygen. When the bacteria is given enough oxygen, it will break down all of the carbon-based organic materials into water and carbon dioxide.

What is the significance of aerator materials?

Plastic, aluminium, galvanised steel, and stainless steel are all typical materials used in marine applications, and each has its own set of advantages and disadvantages.

• While plastic is affordable and relatively robust, UV rays from the sun can cause photochemical degradation of polymers, which means that plastic aerator components exposed to sunlight on a frequent basis may become brittle over time.Even if some polymers do not absorb UV radiation, minute levels of contaminants such as oxygen and salt can act as free radical receptors, causing breaks in the polymer bonds of the plastic. A sinking aerator and significant maintenance issues might result when plastic aerator floats crack.

• Despite its light weight, aluminium is susceptible to corrosion when exposed to salts found in wastewater, brine, saline water, and even reclaimed wastewater. In marine applications, this might lead to additional maintenance issues.

• Galvanized steel is coated with a thin layer of zinc to prevent corrosion. It provides adequate protection against water exposure unless the water contains a significant amount of saline, in which case the galvanised coating is unable to keep the steel from corroding.

• Due to its better corrosion resistance, finish, strength, and stiffness, stainless steel, a chromium-steel alloy, is regarded the preferred material for marine applications. Because it's the best material for aerator construction, Netsol provides all-stainless steel construction.

Maintenance of Aeration Systems

Maintaining an aeration system is critical because failure to do so can lead the system to become ineffective and inefficient, raising your operating expenses. If you choose a diffused-bubble aerator or a packed-tower aerator, the blower must be maintained on a regular basis by replacing old air filters and lubricating the motor. It's highly advised that you keep a log of all the maintenance you do throughout time. This logbook should also contain details of your water test results, which will allow you to monitor the aeration system's effectiveness.

There are 3types of aeration system:

- Diffused Bubble Aerator

- Packed Tower Aerator

- A Spray Aerator

It's also critical to ensure that the area is properly aired when employing one of the three types of aeration systems. Cleaning the trays and tanks in the aeration system on a regular basis is also required if you want to avoid the formation of rust, algae, and sulphur. All of these drugs can reduce the efficiency of your system.

If you follow these maintenance suggestions, you should be able to keep your aeration systems in good working order, extending the system's lifespan and saving money on repairs.

What can Netsol Water provide?

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, ETP and RO Plant manufacture, among other services. We've made it our mission to save the planet. The company creates equipment’s and is committed to providing practical solutions that help businesses flourish. We are committed to providing our valued customers with hands-on service, expert counselling, and training. Every environmental problem and its management have a solution in us.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.