A high-pressure pump is used in the Industrial RO Plants to continuously provide pressure, to the feed stream. The input stream is split into a brine (or reject) stream with a high concentration of dissolved salts, and a "permeate" stream with little or no dissolved salt.

Brine stream is used to continuously rinse out the dissolved salts that the membrane rejected. Reverse osmosis takes place under high pressure in the membrane assembly, as the filtered water from the micron cartridge filter is passed through it. Thus, dissolved contaminants are removed.

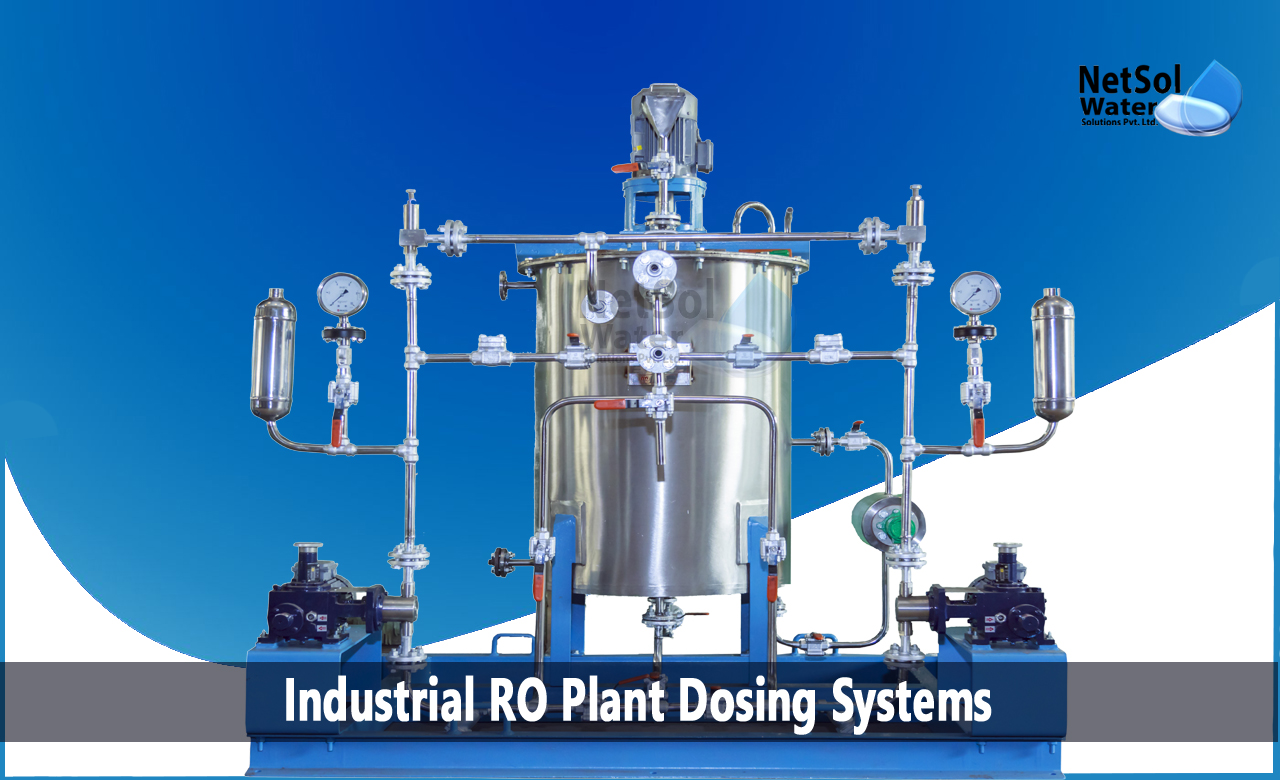

Depending on the raw water analysis and the Industrial RO plant's capacity, recovery can range from 30 to 80 percent. Filtration and de-chlorination after dosing is advised as pre-treatment, to RO post-disinfection. Thus, Industrial RO Plants require proper dosing systems.

What is Industrial RO Plant Dosing Systems?

1. SMBS DOSING SYSTEM

To neutralize the free chlorine in the water, sodium metabisulphite is dosed into the water. If any traces of free chlorine are identified in the water, the ORP analysis provides information about them, and would discard the water.

An SMBS dosing pump, SMBS solution tank, and typical accessories make up an SMBS dosing unit. All oxidising elements from the water must be eliminated before it enters RO membranes. A reducing agent called gets rid of any chlorine residue that remains after UF.

2. ACID DOSING

This system is available to deal with the bicarbonates in water, avoid the formation of scale on the membrane, and lower the slit index.

3. ANTISCALANT DOSING SYSTEM

Antiscalant is dosed in the feed of the Reverse Osmosis to prevent salt precipitation at high pressures, and to keep the salts that cause hardness in suspension. The dosing tank and dosing pump assist in the dosing process.

A solution tank, dosing pump, and common accessories make up an antiscalant dosage device.This dosing method is offered to prevent the RO membrane from scaling, as a result of the high levels of hardness and silica in raw water.

Netsol Water: Industrial RO Plant manufacturers

We regard ourselves as consultants and support the concept well beyond the commissioning stage, including all dosage items. When all the process steps and the individuals participating in the process are well-coordinated, projects can be completed as efficiently as possible. Naturally, our priority is always serving your needs as a customer.

The initial stages of the process are quite important and need special consideration. Consequently, a team of professionals supervise and carry out each step of the procedure. And, this produces an excellent answer for every problem in constant coordination with you.

Working towards ideal dosing pumps with global service

There are many sites where we provide facilities. High quality standards are associated with the quality attributes and as a result, we provide you with further engineering and consultancy, while personally adjusting your system to your workflow.

Why should you select Netsol Water as the manufacturer of your industrial RO plant?

We are the leading producer and supplier of industrial RO systems in India. Our system is exceptionally reliable and cost-effective for use in an industrial environment. We work with each of our clients to give high-quality filtration systems at affordable pricing since, we are aware that you need the best systems available, at fair and competitive prices.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.