How to treat Waste Water containing starch?

After anaerobic processing, starch wastewater has high turbidity and COD, as well as a strong odor. Discharging this type of sewage could cause serious environmental pollution, so it must be treated and meet national standards before being discharged.

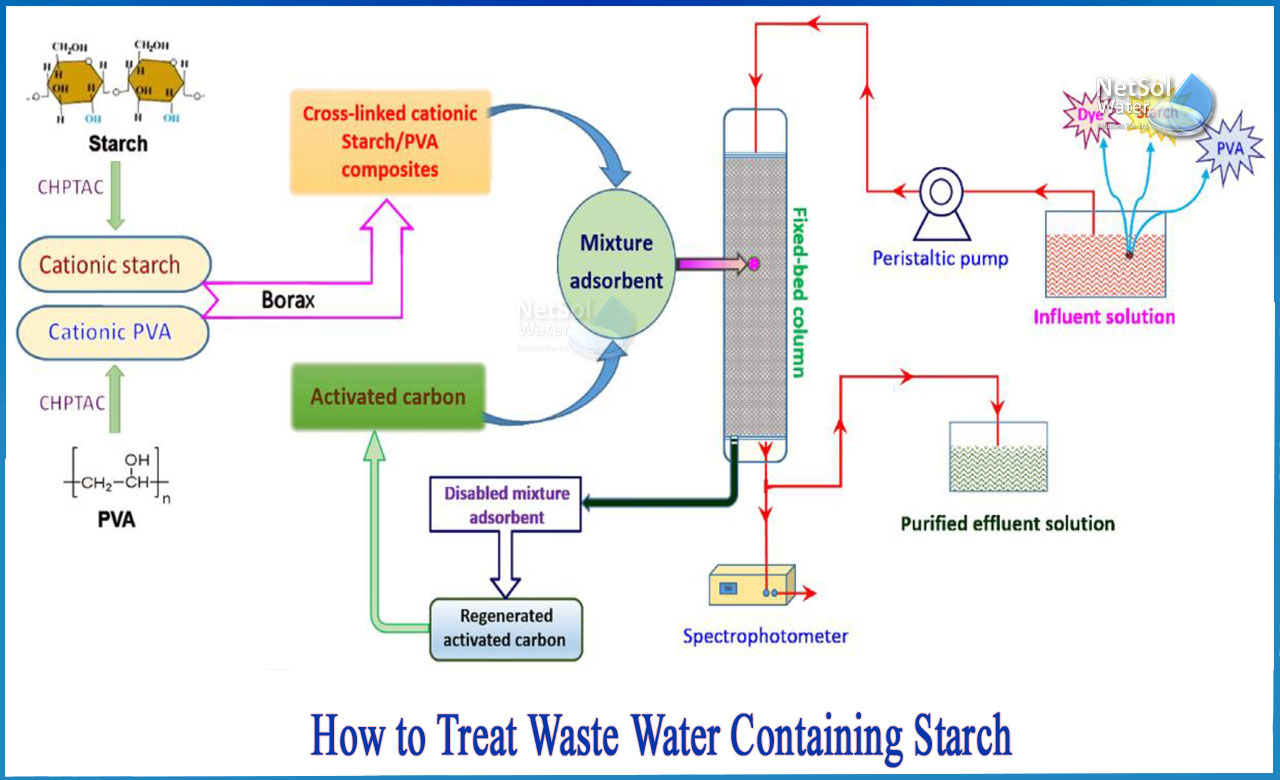

After anaerobic hydrolysis prior to refractory material degradation of simple small molecules, flocculation and sedimentation followed by aerobic treatment in the contact oxidation tank can be used. The contact oxidation pond can be designed to lower the false bottom for filling materials for activated carbon fibers, cycle the water after another ultrafiltration, and then obtain the treated water. In a contact oxidation column, Effective Microorganisms (EM) containing a variety of aerobic and facultative aerobes are used as effective bacteria.

The process has many advantages, such as high efficiency, deodorant properties, and the ability to degrade a wide range of complex materials.

Method of treating wastewater with starch: Technology in the background

Starch industry inclusive of corn, potato, wheat, agricultural-food such as rice, all are raw material productions of starch or starch deep processed product (-amylose, glucose, starch derivative etc.) industry. In the process of production, water requirement is very large. Wastewater discharge is also large, and waste water contains much starch, protein, carbohydrate and the organic high concentrated organic wastewaters such as fat, the dissolved oxygen in water. All of this is consumed.

The present technical solution is to provide a type of starch wastewater treatment method, which includes the following steps:

1. Factory effluent is disposed of in an equalizing tank via a mechanical grille, which prevents precipitation by whipping pastes. Maintain agitation in the equalizing tank, then introduce current into the air flotation pool, and simultaneously add flocculants poly aluminum chloride and polyacrylamide.

2. The water outlet of the air flotation pool flows into the anaerobic reactor, which produces mud and enters the sludge thickener. The water outlet of the pre-exposure settling tank then flows into the SBR reactor device, which carries out the Aerobic biological process, and the mud in the preaeration settling tank and the SBR reactor pond all enters the sludge thickener.

3. After concentrated, mud enters between sludge dewatering and undergoes mechanical dehydration, and the mud cake is transported outward, and the sludge thickener supernatant and mechanism filter-pressing liquid are returned to and regulated settling tank to continue the process.

4. As described, polymerize aluminum chloride is mixed with an aqueous solution with a concentration of 5 percent -10 percent, and the add-on is the 1 percent -2 percent of wastewater flow rate, and polyacrylamide is mixed with an aqueous solution with a concentration of 0.05 percent -0.1 percent, and the add-on is the 2 % -4 % of wastewater flow rate.

This is one of the best technologies for waste water treatment containing starch that has been invented by some companies and researchers and are using it.

Netsol Water comprises of various waste water technologies and expert engineers that can develop and design WWTP’s, ETP’s, STP’s, etc. as per customer needs.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.