How to Treat Detergent Water or Washing Water in ETP?

Detergent water or washing water is generated in large quantities from various industries such as textile, food processing, and chemical manufacturing. The discharge of this wastewater into the environment can cause severe pollution and harm to the ecosystem. To mitigate these risks, it is essential to treat detergent water or washing water in an effluent treatment plant (ETP) before discharging it into the environment.

In this blog, we will discuss the process flow diagram and detailed working function of how to treat detergent water or washing water in an ETP.

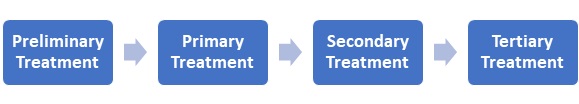

Process Flow Diagram of Effluent Treatment Plant:

The following is the process flow diagram for an effluent treatment plant that can be used to treat detergent water or washing water.

Preliminary Treatment:

The first step in the treatment of detergent water or washing water is preliminary treatment. In this step, large solids such as debris, sand, and grit are removed from the wastewater using a bar screen or a grit chamber. This process ensures that the wastewater is free of large solid particles that can cause blockages in the subsequent stages of the treatment process.

Primary Treatment:

The primary treatment process involves the removal of suspended solids and organic matter from the wastewater. This is done using a primary clarifier, which is a large tank that allows the wastewater to settle. The settled solids form a sludge layer at the bottom of the tank, while the clarified wastewater is removed from the top. This process removes up to 60% of suspended solids and 30% of organic matter from the wastewater.

Secondary Treatment:

The secondary treatment process involves the removal of dissolved organic matter and nutrients from the wastewater. This is done using biological treatment processes such as activated sludge process, trickling filter process, or sequencing batch reactor (SBR) process. In the activated sludge process, the wastewater is mixed with a bacterial culture (activated sludge) in a tank. The bacteria consume the organic matter in the wastewater and convert it into carbon dioxide and water. The clarified water is then separated from the sludge in a secondary clarifier. The trickling filter process involves passing the wastewater over a bed of rocks or plastic media, where the bacterial culture grows and consumes the organic matter in the wastewater. The SBR process is similar to the activated sludge process, but the treatment occurs in a single tank.

Tertiary Treatment:

The tertiary treatment process involves the removal of residual suspended solids, nutrients, and trace contaminants from the wastewater. This is done using physical and chemical treatment processes such as filtration, adsorption, and disinfection. In the filtration process, the wastewater is passed through a sand or membrane filter, which removes any remaining suspended solids. In the adsorption process, activated carbon or ion exchange resins are used to remove trace contaminants from the wastewater. In the disinfection process, the wastewater is treated with chlorine or ultraviolet (UV) light to kill any remaining bacteria or viruses.

Detailed Working Function of Effluent Treatment Plant:

Preliminary Treatment:

The preliminary treatment process involves the removal of large solids such as debris, sand, and grit from the wastewater. This is done using a bar screen or a grit chamber. The wastewater is passed through a bar screen, which removes any large solid particles such as sticks, rags, and plastics. The wastewater is then sent to a grit chamber, where sand and grit settle to the bottom of the tank. The settled grit is removed using a scraper or a suction pump.

Primary Treatment:

The primary treatment process involves the removal of suspended solids and organic matter from the wastewater. This is done using a primary clarifier, which is a large tank that allows the wastewater to settle. The wastewater is passed through the primary clarifier, where the suspended solids settle to the bottom of the tank and form a sludge layer. The clarified wastewater is then removed from the top of the tank and sent for further treatment. The sludge layer is removed from the bottom of the tank using a scraper or a suction pump and sent for further treatment.

Secon?dary Treatment:

The secondary treatment process involves the removal of dissolved organic matter and nutrients from the wastewater. This is done using biological treatment processes such as activated sludge process, trickling filter process, or sequencing batch reactor (SBR) process. In the activated sludge process, the wastewater is mixed with a bacterial culture (activated sludge) in a tank. The bacteria consume the organic matter in the wastewater and convert it into carbon dioxide and water. The clarified water is then separated from the sludge in a secondary clarifier. The sludge from the secondary clarifier is sent back to the primary clarifier for further treatment.

In the trickling filter process, the wastewater is passed over a bed of rocks or plastic media, where the bacterial culture grows and consumes the organic matter in the wastewater. The treated water is then passed through a secondary clarifier to separate the clarified water from the sludge. The sludge from the secondary clarifier is sent back to the primary clarifier for further treatment.

The SBR process is similar to the activated sludge process, but the treatment occurs in a single tank. The wastewater is mixed with the bacterial culture in the tank, and the organic matter is consumed by the bacteria. The treated water is then separated from the sludge in the same tank. The sludge is then removed from the bottom of the tank and sent for further treatment.

Tertiary Treatment:

The tertiary treatment process involves the removal of residual suspended solids, nutrients, and trace contaminants from the wastewater. This is done using physical and chemical treatment processes such as filtration, adsorption, and disinfection. In the filtration process, the wastewater is passed through a sand or membrane filter, which removes any remaining suspended solids.

In the adsorption process, activated carbon or ion exchange resins are used to remove trace contaminants from the wastewater. The treated water is passed through a bed of activated carbon or ion exchange resins, which adsorb the contaminants. The treated water is then separated from the adsorbent using a filter or a clarifier.

In the disinfection process, the wastewater is treated with chlorine or ultraviolet (UV) light to kill any remaining bacteria or viruses. In the chlorine disinfection process, chlorine is added to the treated water, and the water is mixed thoroughly to ensure that the chlorine is evenly distributed. The water is then allowed to sit for a specific period to ensure that all the bacteria and viruses are killed. The chlorine is then removed using a dechlorination process.

In the UV disinfection process, the treated water is passed through a chamber where it is exposed to UV light. The UV light kills any remaining bacteria or viruses in the water. The treated water is then sent for storage or discharge into the environment.

Conclusion:

Treating detergent water or washing water in an effluent treatment plant is essential to prevent pollution of the environment. The process involves four main stages: preliminary treatment, primary treatment, secondary treatment, and tertiary treatment. Each stage of the treatment process removes different contaminants from the wastewater. Effluent treatment plants can be customized to meet the specific needs of different industries. By following the process flow diagram and detailed working function discussed in this blog, industries can effectively treat their detergent water or washing water and contribute to a cleaner environment.

You may reach us by phone at +91-9650608473 or by email at enquiry@netsolwater.com if you have any questions about our products, services, or support.