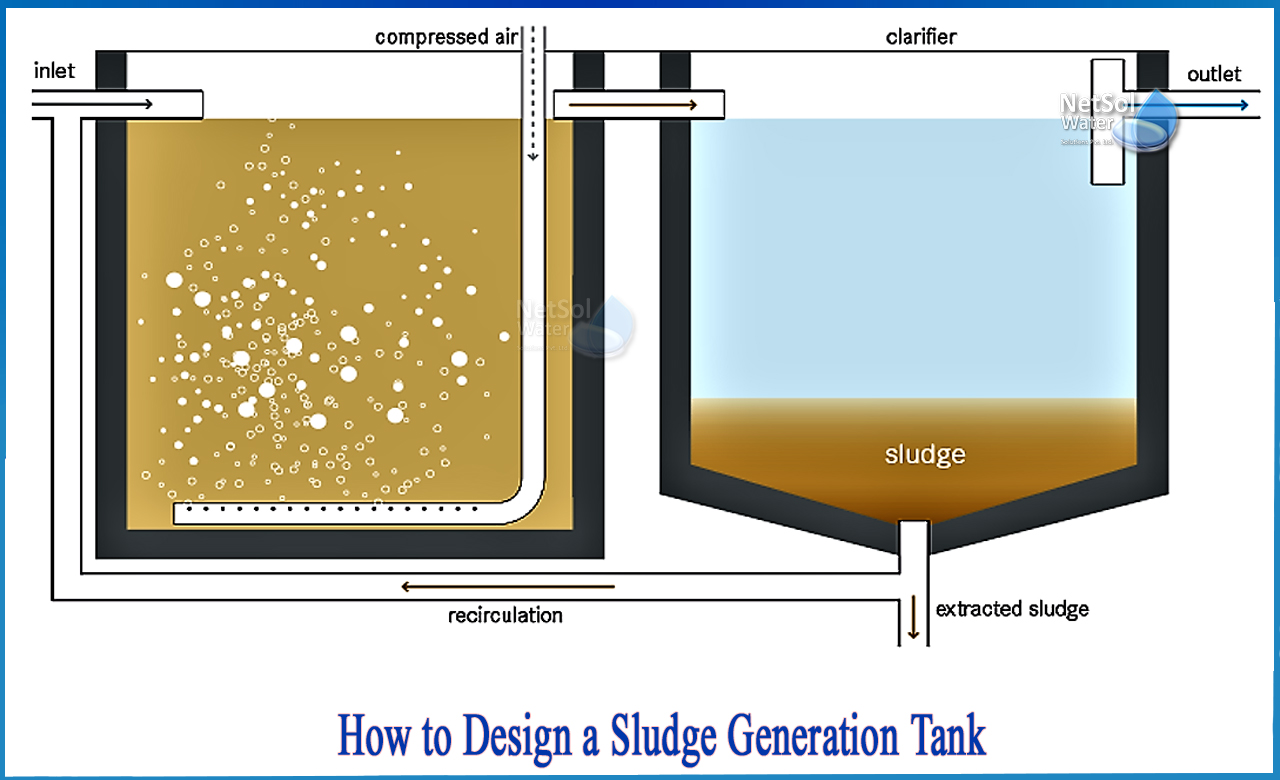

How to design a sludge generation tank?

Sludge digestion is the treatment of highly concentrated organic wastes by anaerobic microorganisms in the absence of oxygen. Two phases are involved in the anaerobic treatment of organic wastes, which results in the creation of carbon dioxide and methane.

Complex waste components, such as lipids, proteins, and polysaccharides, are initially digested by a heterogeneous group of facultative and anaerobic bacteria in the first stage, referred to as "acid fermentation." The hydrolysis products are subsequently fragmented, bi-oxidized, and subjected to various metabolic processes, resulting in the creation of simple organic molecules, primarily short-chain (volatile) acids and alcohols. Several different kinds of strictly anaerobic bacteria convert the first stage's end products to gases (mostly methane and carbon dioxide) in the second stage, referred to as "methane fermentation”.

Acid fermentation bacteria are more resistant to changes in pH and temperature, and they develop at a much faster rate than methane fermentation bacteria. When the pH falls below 6.0, methane generation almost completely stops, and additional acid accumulates, bringing the digestion process to a halt. As a result, methane fermentation is commonly thought to be the anaerobic wastewater treatment rate limiting step.

The methane bacteria are active in both the mesophilic (27-43°C) and thermophilic (35-40°C) temperature ranges, with digesting times of four weeks and 15-18 days, respectively. However, due to odour and operational issues, thermophilic range is not used.

The needed capacity of the sludge digestion units is determined by the following factors while designing the digestion tanks:

I) The amount of sludge that needs to be digested.

(ii) After digestion, a certain amount of sludge remains.

(iii) The detention time or the period required for the digestion.

The required capacity of the digesting tanks is calculated mathematically by:

= (Digestion time in days) (5/8 to 2/3 the daily volume of entering raw sewage)

However, because the digestion tanks destroy the volatile organic matter in the sludge, their capabilities are measured in terms of the amount of volatile organic material destroyed every day (or month) per cubic metre of tank volume. Because sewage sludge per capita is rather stable in most municipalities, the capabilities of sludge digestion units can also be represented in cubic metres per capita per day.

Digester Elements Design:

1-Number of Units

Traditional digesters are built as single units to treat up to four medium plants. Units should be provided in multiples of two for bigger plants, with individual capacity not exceeding 3 MLD. Digesters with a high rate of digestion are created. Each unit, which consists of primaryand secondary digestion tanks, is normally capable of handling up to 20 MLD of sludge from treatment plants.

2-Shape and size of tank

For sludge digestion, circular tanks are the most frequent, and they should have a diameter of less than 6 m and no more than 55 m.

3-Depth of Water

A digester's side water depth should be kept between 4.5 and 6.0 metres, but not more than 9 metres. The depth of sludge in a digester must be carefully calculated, since a too deep digester can create excessive foaming and clogging of the gas mains, resulting in dangerously high pressures in the digester. When the gas output reaches around 9 m3/d/m2 of top, sludge surface foaming becomes visible.

As a result, the maximum gas production rate should be calculated before choosing on tank depth and surface area. Per kg of volatile materials destroyed, about 0.9 m2 of gas is created. The digester's optimum diameter or depth is calculated so that the value of 9m3/m2 of tank area is not exceeded at twice the average rate of daily gas generation.

4-Free Board

The free board between the liquid level and the top of the digester wall should not be less than 40 cm for fixed dome or conical roofs. The free board between the water level and the top of the tank wall should ideally be no less than 60 cm for floating covers. The free board for a permanent roof slab should be 80 cm.

5-Characteristics of the Bottom Slab

To make sludge removal easier, the bottom of the digester should have at least 1 in 12 slopes. The tank's floor should be designed to withstand uplift pressure caused by subsoil water or adequately protected by anchoring or pressure release valves.

6-Roof

The sludge digester can have a fixed or floating roof. For the permanent roof, R.C.C. domes, conical or flat slabs are employed, and for the floating cover, steel domes are used. Steel floating covers can either float on top of the liquid or serve as gas holders within the digesters. A vertical travel of 1.20 to 2.0 m should be supplied when the floating cover is utilised as a gas holder in a digestion tank.

For more information, contact Netsol Water!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.