Some of the most crucial compounds used in contemporary produced goods are phenols. They are a common component in paint, aspirin, analytical kits, medications, and other specialty chemical products.

It's true to say that without them, modern life as we know, it would definitely come to an end. They genuinely serve as the foundation for contemporary chemistry, enabling skilled chemists to produce goods that are ever more efficient.

Phenols are highly practical "commodity" compounds. They must be handled with extreme caution, because they are truly highly harmful when concentrated. As a result, handling and treatment of phenols is necessary, either from water or wastewater.

What are Phenols?

Phenols are comparable to alcohols but are more soluble in water, and hence more likely to be undesired components of industrial wastewater, because they form stronger hydrogen bonds.

Although, phenols are now frequently used as a disinfectant in cleaners and mouthwash (of course in low concentrations), a small amount of concentrated phenol on the skin can cause severe burns and may even be fatal.

Why remove phenols from wastewater?

Phenols can interact with other substances in water to create exceedingly dangerous chemicals, which are destructive to both aquatic and terrestrial life. For this reason, phenolic compounds are recognized as pollutants of priority concern.

In order to avoid negative publicity and fines for the environment, chemical manufacturers who utilize phenol must take great care not to discharge phenol.Fortunately, Netsol’s technology is ideal for removing these substances down to undetectable levels.

How can phenols enter industrial wastewater?

These undesirable substances can enter industrial wastewater in two primary ways, and both are unavoidable by-products of many manufacturing processes.

In the production process, which also uses phenols, water is used.Any maintenance or wash-down procedures will increase the amount of phenols, in the water utilized.It makes logical to cleanse plant effluent as much as possible, because water is becoming more expensive and occasionally even less available. Numerous businesses are beginning to evaluate the potential of ZLD (zero liquid discharge). Using RO Plants and ZLD makes this possible.

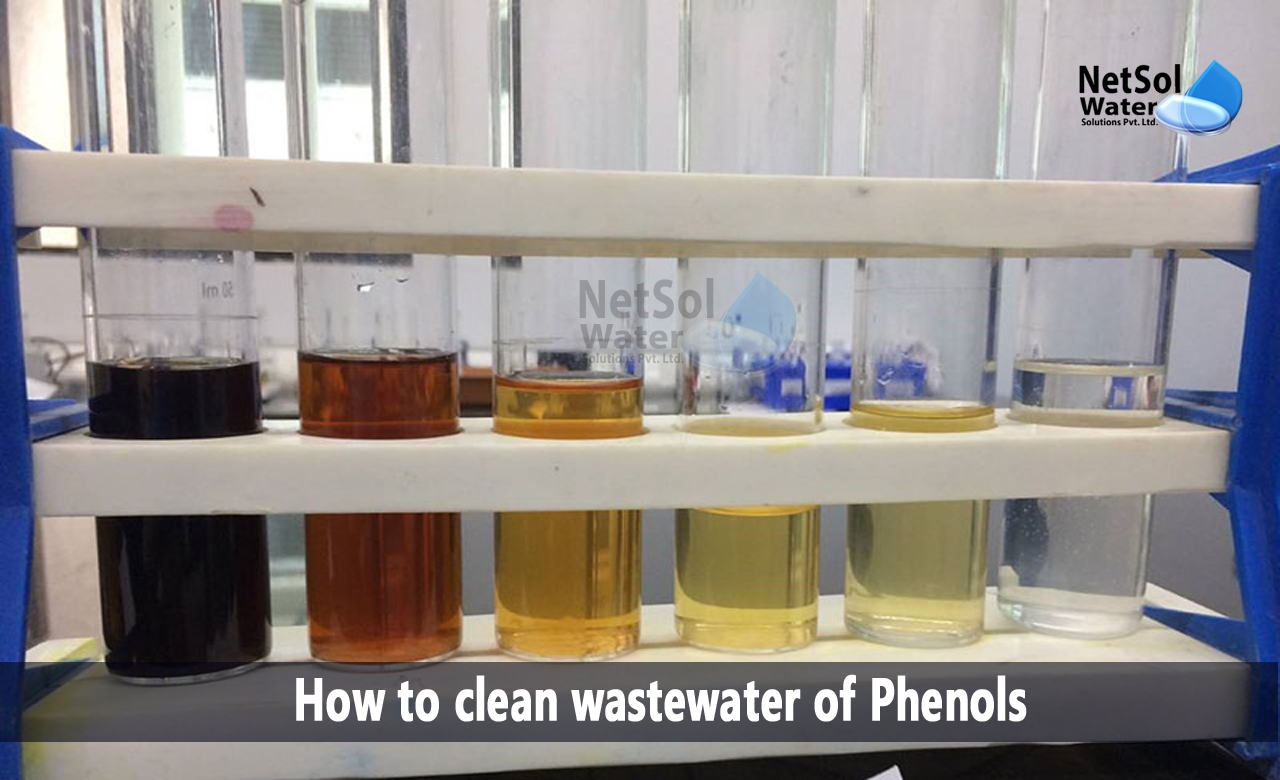

How to clean wastewater of phenols?

The majority of the businesses Netsol Water works with are big enough to have trade effluent consents in place, which will specify the purity of the wastewater, so they are worried about abiding by the rules as well as minimizing harmful exposure.

By addressing the problems frequently associated with conventional AOPs (advanced oxidation processes), our wastewater treatment system offers a reliable and efficient method for the removal of organics. It can be positioned at various locations in a variety of industrial water cleaning processes and functions, through a special mix of adsorption and oxidation.

Safeguarding further wastewater treatment procedures

However, because of the harm that phenols can do to a biological or RO system, they must be used in conjunction to produce the best results. Biological and reverse osmosis water cleansing are ideal for removing unwanted compounds.

In order to solve these concerns, we frequently advise a more modular strategy with our equipment, installed in various crucial locations across a plant. All systems have a minimal footprint, are scalable, have no moving components, and don't require chemical dosing. In addition, unlike many other water treatment systems, they do not produce hazardous sludge.

If a GAC receives too much phenol, it can get saturated before it needs to be renewed, which would violate the discharge certifications

It is customary to carry insurance against oversaturation and any associated environmental fines, but doing so significantly raises the cost.The most cost-effective option is probably to have a very small GAC operation in a facility, and change the medium only twice a year.

As an additional water-treatment technology, choose Netsol’s advanced treatments

Our polishing systems are typically used as a third stage of water treatment, after mechanical and biological systems in various industries, like RO Plants or water softeners or ZLD Plants.

However, when dealing with high phenol concentrations, our systems frequently need to come in second place after mechanical filtering, because phenols will otherwise damage many of the biological or RO system's active components, and render them useless. In RO systems, phenols can readily destroy the expensive-to-replace membranes.

Our advanced wastewater treatment systems often functions as a supplementary technology, removing particular resistant and dangerous organic chemicals, while safeguarding already-existing processes like biological systems or RO Plants.

Benefits of our wastewater treatment systems

The primary benefit of wastewater treatment systems is that the process leaves no residue, resulting in low maintenance, maximum up-time, and no harmful residue that needs to be removed and incinerated. This is in addition to efficiency and great performance.

In many specialised chemical processes, our new-generation devices can effectively decrease phenols to parts per trillion, well below the limit of detection. Our system is especially effective in treating phenols at both low and high flow rates, as a result of the way it functions, combining absorption and oxidation.

The principal gains are:

· Zero waste

The most recent system from Netsol Water combines adsorption and oxidation into a single, compact device that destroys impurities completely and on-target without creating any additional waste.

· No dosage is necessary

By using our products, you can prevent problems with chemical handling and storage, training for maintenance staff, compliance, paperwork related to risk assessments, and adverse environmental effects.

· On-site treatment

WWTPs eliminate the enormous expenses and damaging effects on the environment, of routinely transporting and discarding media or sludge. During the healing process, our media is also being renewed. The reactor just requires a yearly basic top up.

· High uptime

Processes don't have to be stopped like they would if solely a RO process was being used, in order to clean or replace fouled membranes.

Still not sure how our water and wastewater treatment plants are the best solution, for your wastewater treatment needs?

The first step is to determine the quality of water you have and the water you require. To assist you with this procedure, we provide a free water analysis test, and the most advanced treatment systems for removing phenols from wastewater.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.