Prior to boiler, cooling, and reverse osmosis systems, water softeners are used which are ion exchange system created to eliminate the calcium and magnesium ions, which cause scale to form. The softener capacity, which can be represented in either grains or gallons, is the amount of hardness a softening can remove between regenerations. When sizing, setting up, or troubleshooting a softener, capacity is crucial.

The instrument is important for figuring out how much softener resin is needed, OBR (output before regeneration), and the amount of salt and water needed during the regeneration process.

Let’s understand the concept of OBR calculation of water softener.

How to calculate OBR in water softener?

1. The hardness of raw water in ppm

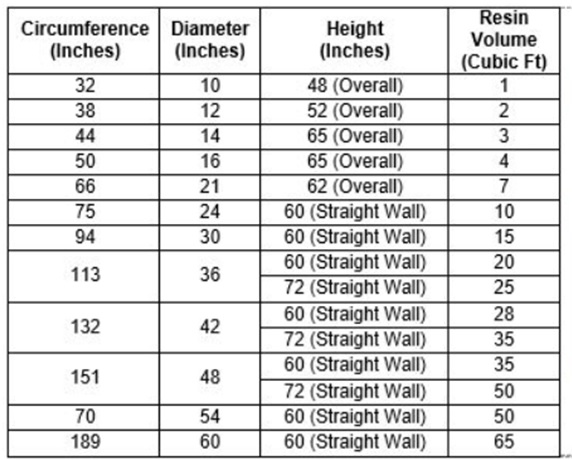

2. The volume of resin in cubic feet (ft3)

3. Salt dose in pounds (lbs) per square foot of resin

The following table can be used to compare the tank circumference and height to the resin volume, if the resin volume is unknown. The resin exchange capacity is dependent on the salt dosage during regeneration. An exchange capacity of 30,000 grains/ft3 resin is typically provided by a salt dosage of 15 lbs/ft3 resin. Salt saver dose is based on lower salt dosages since they allow for more cost-effective salt usage, while reducing capacity.

How is the resin capacity calculated in a water softener?

The product's supplier's Data Sheet mentions the resin exchange capacity.

One unit of resin = (Feed Hardness in ppm X Water Quantity m3)/ (Exchange capacity).

How much salt is required?

150 Grams of NaCl per liter of resin, or 110 Kg of NaCl is generally required.

So, a certain amount of water is needed to dilute a 100% solution.

= say, 320 grams of NaCl dissolved in a liter of water at 20 degrees Celsius.

Add 3440 liters of water to create a 10% solution.

Currently, 3784 liters must be infused with that much water in 20 minutes for regeneration.

Then, begin the backwash process for an additional 40 minutes.

After a brief washing to bring the hardness below 5 ppm, the unit is now ready to start extracting up to 100 m3.

Feed pressure must be kept between 1.5 and 2 bars, and exchange capacity is crucial; it varies from product to product.

Conclusion

One of the most prevalent issues with water quality that many homeowners have is water hardness, which is removed by a water softener. Hard water dries out hair and skin, damages appliances, and creates a film of soap scum all over bathrooms and kitchens. Water softeners are essential because over 85% of Indians use hard water for cooking, washing, and bathing.

A water softener saves you from spending many hours cleaning off soapy residue, and replacing prematurely damaged water heaters, and scaly faucet heads. You may save time, effort, and money, and safeguard your house and property by investing in a water softener.

What do we offer?

One of India's top producers of water treatment facilities is Netsol Water Solutions. In order to provide our customers with a solution created to operate with our purification and filtration plant, we have introduced a specific line of water treatment plants and wastewater treatment plants which include physiochemical and biological processes.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.