What is Nanofiltration Method of Wastewater Treatment?

Nanofiltration is an advanced wastewater treatment technology that utilizes membranes with pores in the nanometer range to remove contaminants from water. It is considered a pressure-driven membrane process that can effectively remove multivalent ions, organic compounds, and other pollutants that are smaller than 0.001 microns. Nanofiltration offers several advantages over traditional water treatment methods, including high permeability, excellent removal efficiency, and relatively low energy consumption. For these reasons, nanofiltration has emerged as a promising technology for water recycling and purification, especially for challenging wastewaters from industries like textiles, pharmaceuticals, and food processing.

Principles of Nanofiltration

Nanofiltration membranes typically have pore sizes ranging from 1-10 nanometers, which is larger than reverse osmosis membranes but smaller than microfiltration and ultrafiltration membranes. These tight nano-scale pores allow nanofiltration membranes to reject divalent and multivalent ions, organic molecules, sugars, proteins, and other contaminants based on a combination of size exclusion and electrostatic repulsion mechanisms.

The key aspects that determine the separation performance of nanofiltration membranes are:

1- Molecular weight cut-off - Pore size distribution and geometry that determines which compounds can pass through or get rejected.

2- Surface charge - The surface charge repels ions of the same charge. Nanofiltration membranes usually have a negative surface charge.

3- Water permeability -Determines the membrane's filtering capacity. Higher permeability requires lower operating pressures.

4- Ion rejection - Ability of the membrane to reject charged dissolved contaminants based on Donnan exclusion principles. Magnitude of rejection depends on size and charge.

In essence, nanofiltration leverages size exclusion and electrostatic interactions to separate ions, organic matter and other impurities from water.

Applications in Wastewater Treatment

Nanofiltration has proven to be a versatile technology for treating a wide range of municipal and industrial wastewaters due to its fine pore structure:

1- Municipal wastewater -Effective for disinfection and removal of bacteria, viruses, pharmaceuticals, endocrine disruptors, and other trace organic contaminants.

2- Textile industry wastewater -Used for color removal and recovery of dyes/salts from dyeing effluents. Removes color while allowing salt passage.

3- Food and beverage industry -Suitable for simultaneously concentrating, de-salting, and removing organics from wastewater streams.

4- Landfill leachate -Removes refractory and toxic organic compounds from contaminated leachate.

5- Oil and gas industry -Separates emulsified oils and suspended solids from produced water and refinery effluents.

6- Metal/mining industry - Recovers precious metals, rejects heavy metal ions and purifies acid mine drainage.

7- Semiconductor industry - Purifies and recycles ultrapure water used in wafer fabrication processes.

Thus, nanofiltration can be tailored for site-specific pollutants and effluent standards by proper membrane selection and system design.

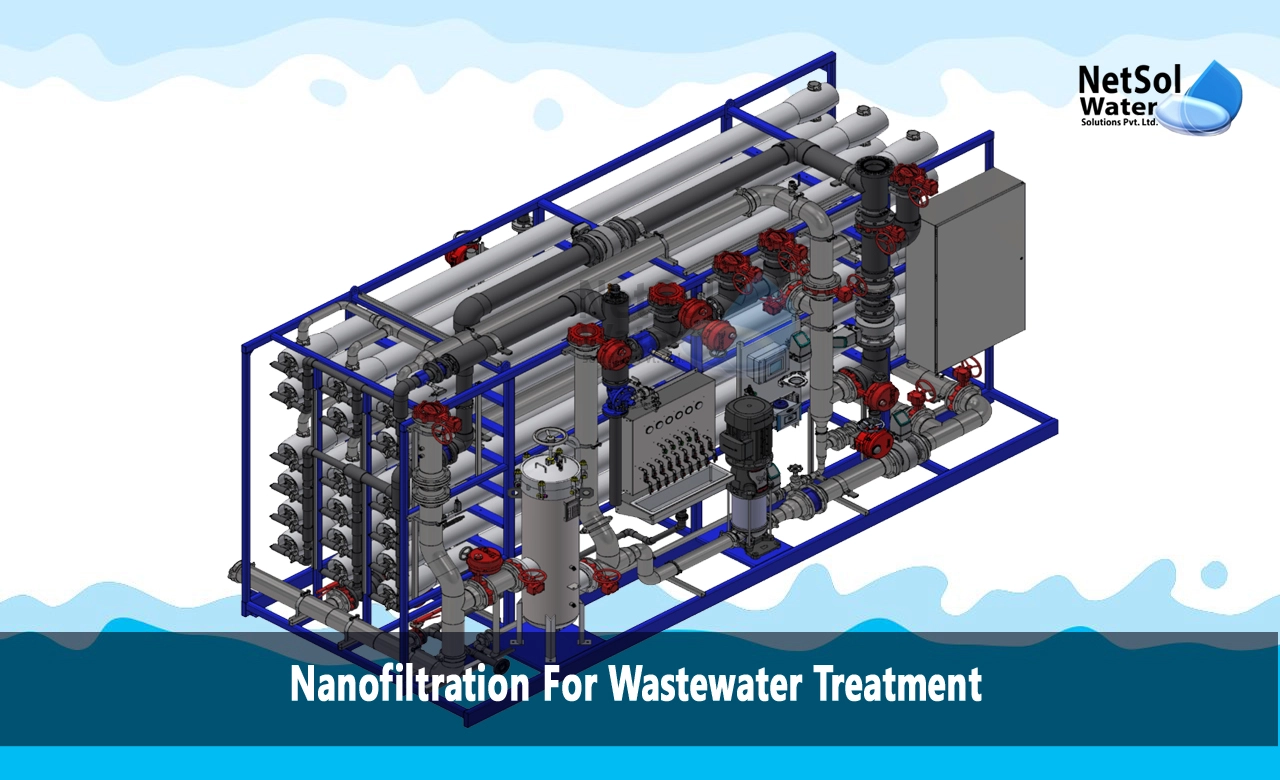

System Design and Operational Considerations

Nanofiltration systems need to be custom designed based on the wastewater properties and treatment objectives. Key design factors include:

1- Membrane material and orientation -Determines separation characteristics. Polymeric membranes like polyamide are commonly used. Can be configured as hollow fiber or spiral wound modules.

2- Operating pressure - Typically varies from 70-150 psi based on water chemistry and membrane properties. Higher pressure improves separation but increases costs.

3- Water pre-treatment - Raw wastewater needs pretreatment like screening, coagulation, softening to prevent membrane fouling.

4- Module configurations - Membranes can be arranged in parallel or series stages for efficient contaminant separation.

5- Chemical cleaning - Periodic cleaning using acids, alkalis, detergents isrequired to restore membrane performance.

Critical process parameters that affect nanofiltration efficiency and operating costs include pH, temperature, flow velocity and fouling control. Automated sensors to monitor membrane pressure drop, conductivity and permeate flow rate allows optimized performance.

Future Outlook and Conclusion

With its unique abilities to remove challenging contaminants, nanofiltration has proven to be a key enabling technology for efficient and eco-friendly wastewater purification and recycling. Ongoing membrane developments are expanding nanofiltration capabilities for demanding industrial effluents and hard-to-treat wastewaters:

1- Fabrication of novel nanoporous substrates with superior permeability, fouling resistance and separation efficiency.

2- Surface modifications using nanomaterials to enhance membrane hydrophilicity, permeability and selectivity.

3- Integration of nanofiltration with other technologies like activated carbon adsorption, UV oxidation to design compact hybrid systems

4- Development of antifouling and self-cleaning membrane technologies to reduce operating costs.

5- Use of renewable energy sources like solar PV to power treatment systems and reduce carbon footprint.

However, the high membrane cost is still a constraint for widespread adoption. With upcoming improvements in membrane fabrication methods, nanofiltration costs are likely to go down, enabling its use for small scale decentralized systems.

In summary, nanofiltration is an exceptionally versatile green technology that can enable sustainable water reuse across diverse industries. With ongoing technology refinements, nanofiltration is poised to make a substantial impact in efficient wastewater purification, zero liquid discharge systems and aquatic environmental protection in the coming decades.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com