The color of water is one of the most visible parameters that can have a significant impact on its quality. It can be caused by a variety of factors, including natural substances, such as tannins and humic acids, as well as anthropogenic sources, such as industrial effluents and agricultural runoff. Color can be a sign of organic matter, bacteria, algae, or other contaminants in the water. Color removal units are commonly used in water and wastewater treatment processes to remove color from the water.

Let us learn about color removal units and their working.

What is a Color Removal Unit in Water and Wastewater Treatment?

A color removal unit is a device that is used to remove color from water or wastewater. It is an essential component of many water treatment plants that must meet strict water quality standards. The unit removes color by utilizing a variety of physical and chemical processes, including:

· Adsorption,

· Coagulation,

· Flocculation,

· Oxidation, and

· Biological treatment.

Best Solutions:

Some of the technologies used for color removal are:

1. Nanofiltration System:

Reverse osmosis-style systems are comparable to nanofiltration (NF) systems in design. The difference between the two, though, is in the degree of filtration. Water with low levels of total dissolved solids or organic matter uses nanofiltration devices. The optimum solution to handle both softening and demineralization would be the NF system. The NF system is distinctive because it performs both filtration and softening tasks. NF systems are able to soften the water while also removing a certain amount of impurities thanks to their softening membranes. Although less comprehensive than a reverse osmosis system, the level of filtration does eliminate impurities that could have given water a discoloured appearance. Membrane filtering is used in this procedure.

2. Activated Carbon Filter:

The most popular method of removing color from water is an activated carbon (AC) filter. This traditional treatment is intended to absorb particles and organic pollutants in water that could cause unpleasant tastes and odours, in addition to removing color from the water. This treatment approach can also filter out turbidity and iron. It's crucial to realize that activated carbon filters do not eliminate microorganisms, though. Thus, it is described as filtration as opposed to purification. One of the least expensive treatment options, AC filters can be quite successful in lowering dissolved solids.

Here we will use Activated Carbon Filter.

Working Function.

The working function of a color removal unit can be divided into three main stages:

1. Pre-Treatment:

The first stage of the process is pre-treatment, which involves screening the water to remove large particles and debris that may interfere with the subsequent treatment steps. This stage is essential in protecting downstream equipment and ensuring efficient operation of the color removal unit.

2. Treatment:

The second stage of the process involves the actual color removal process. The coagulation, flocculation, sedimentation, filtration, and adsorption processes work together to remove color from the water. Coagulation involves adding a chemical coagulant, such as aluminum sulfate, to the water to destabilize the colloidal particles and facilitate their aggregation. Flocculation involves gently stirring the water to promote the formation of large flocs. Sedimentation involves allowing the flocs to settle in a sedimentation basin, and the clear water is then decanted from the top. Filtration involves passing the clarified water through a filter bed to remove any remaining particles and impurities. Finally, adsorption involves passing the water through an activated carbon bed or resin bed to adsorb any remaining color molecules.

3. Post-Treatment:

The final stage of the process involves post-treatment, which involves disinfecting the water to remove any remaining bacteria or pathogens. Disinfection can be achieved through various methods, including chlorination, ozonation, and ultraviolet (UV) radiation.

Process of a Color Removal Unit:

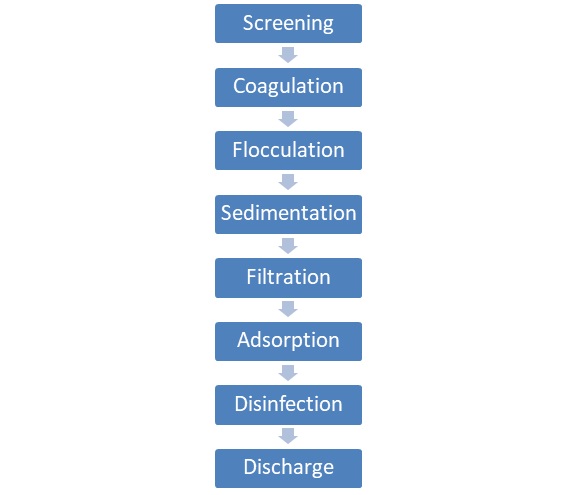

The process used in a Color Removal Unit can be understood by the flow diagram below:

The following is a process flow diagram of a typical color removal unit in a water or wastewater treatment plant:

1. Screening: The first step in the process is to screen the water to remove large particles and debris.

2. Coagulation: In this step, a coagulant is added to the water to destabilize the colloidal particles and facilitate their aggregation.

3. Flocculation: After coagulation, the water is subjected to gentle stirring to form large flocs.

4. Sedimentation: The flocs settle in a sedimentation basin, and the clear water is then decanted from the top.

5. Filtration: The clarified water is then passed through a filter bed to remove any remaining particles and impurities.

6. Adsorption: The water is then passed through an activated carbon bed or resin bed to adsorb any remaining color molecules.

7. Disinfection: The final step is to disinfect the water to remove any remaining bacteria or pathogens.

Summary:

Color removal units are essential components of water and wastewater treatment plants. They play a crucial role in ensuring that the water meets strict quality standards by removing color and other impurities. The color removal process involves a series of physical and chemical processes, including coagulation, flocculation, sedimentation, filtration, and adsorption. The process flow diagram and working function of a color removal unit described above provides a general overview of the process. However, the specific design and operation of a color removal unit may vary depending on the water source, the nature of the color, and the quality standards that must be met.

Overall, color removal units are a vital tool in ensuring that water and wastewater are safe for human consumption and the environment. By removing color and other impurities, they help to protect public health and promote sustainable water management practices.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.